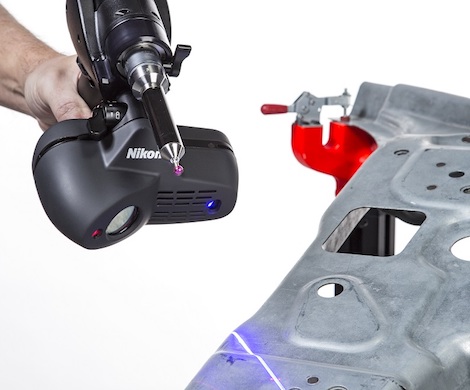

Nikon Metrology has launched the latest update to its range of portable laser scanning devices.

The new ModelMaker H120 is based on Nikon’s blue laser technology which features an ‘ultra-fast frame rate’, specially developed optics and the ability to measure the most challenging materials – something that lower end laser scanner (and some more pricey ones as well) struggle with.

Having a field-of-view width up to 120 mm and a point resolution down to 35 μm, the system is said to be ideal for users requiring fast, detailed data collection over a large area.

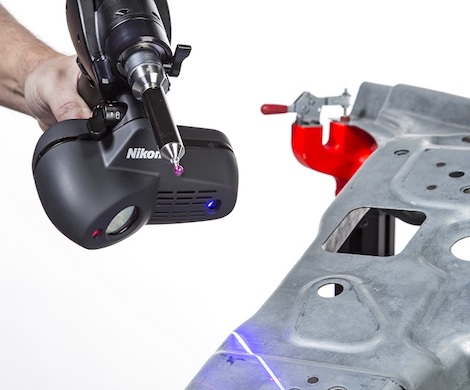

A frame rate of over 450Hz is available even when measuring difficult surfaces such as carbon fibre and gloss black as well as reflective or multi-coloured parts. With 2,000 points per scan line and no reliance on point-to-point interpolation to artificially boost data density, it is possible to measure very small details on large surfaces even when cycle time is critical.

ModelMaker H120 uses advanced Nikon optics and a blue, low speckle laser to generate high accuracy, low noise data, making it possible to clearly identify small scratches and abrasions on a surface.

In addition to rapid collection of surface data, sharp edges are represented with clarity thanks to a scanner accuracy of 7 μm and a combined system accuracy with Nikon Metrology’s MCAx articulated arms of up to 28 μm.

The fourth generation of the company’s Enhanced Sensor Performance (ESP4) dynamically adapts the laser source intensity not just for every scan line, but for every point in each scan line, enabling parts with significant colour changes or reflectivity to be measured from any angle.

This minimises the need for training, as a single scanner setting is capable of measuring almost all parts encountered in industrial metrology applications.

Thermal stability and temperature compensation eliminate the need for a warm-up period. The user simply connects the unit to a PC using a USB cable, powers on and starts scanning within a few seconds.

Real-time feedback is provided by display of the boundaries of the measurement area, ensuring that scanning is always from the optimal position.

An integrated locking mechanism provides a simple, user-friendly and repeatable connection to MCAx arms of different sizes and specifications throughout a facility, so there is no need to move the whole arm assembly.