//giphy.com/embed/LRQEKMLgVgQyA

A collaboration between Krone Golf and an experienced Italian parts manufacturer, CRP Group, has resulted with the creation of the KD-1 composite driver clubbed, where the different materials have a specific function and structural competence.

While titanium and composite materials have been used in the golf industry for nearly 20 years, very little has been done to take full advantage of how they are used to optimise the design or part performance.

Krone was determined to create the world’s most advanced high-performance golf equipment and decided to break away from the ‘mass produced’ manufacturing techniques favoured by big brands.

Having done extensive research and testing of different additive manufacturing processes such as laser sintering of titanium, and 3D printing of wax for casting patterns, Krone found that some of the results were quite promising there were also quite a few issues with accuracy, repeatability , and part quality.

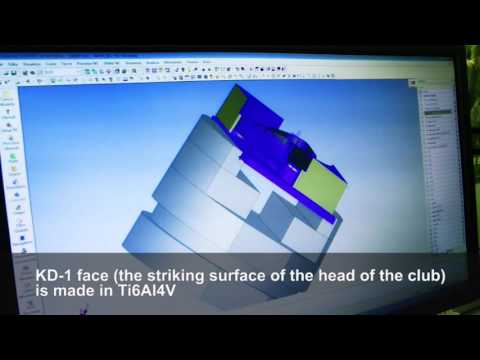

The choice was made to combine FDM 3D printing for the main body, while high precision CNC machining would finish the face of the club – all under the design and manufacturing guidance of CRP Group from its base in Modena, Italy.

The engineering behind a great golf driver involves optimising the thickness of each surface, controlling total weight of the head, and tuning the center of gravity of the assembly.

“It’s a balancing act to get everything right,” explains The various rules committees for professional golf have placed limitations on the maximum size and volume that a golf driver can be – so engineers are constrained to design within a certain ‘box’,” said Krone CEO Marc Kronenberg.

“We see the opportunity to do something revolutionary in the golf industry and design a superior product through the use of intelligent design, innovative materials, and high tech manufacturing methods.”

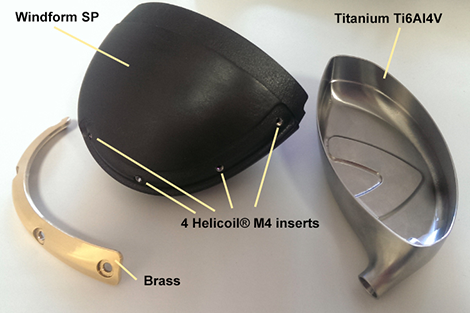

The 3D print was built in CRP Group’s own Windform SP filled carbon FDM material, which allowed for the creation of a very stiff lightweight structure with 3D lattice geometries.

A CNC machined titanium face was easily attached, and the design allowed for helicoil screw inserts to be easily added, to attach a machined brass rear weight that could be used to tune the club.