HSMWorks 2015 offers support for the latest high-end workstations, meaning faster tollbooth calculations

Autodesk has announced the release of HSMWorks 2015, its fully integrated CAM solution for users of SolidWorks software, the third since it acquired the HSMWorks product line.

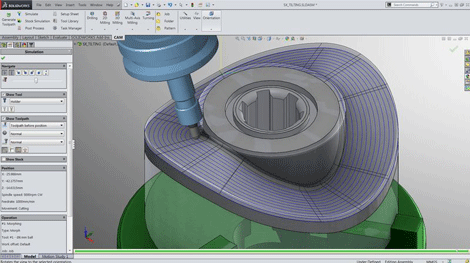

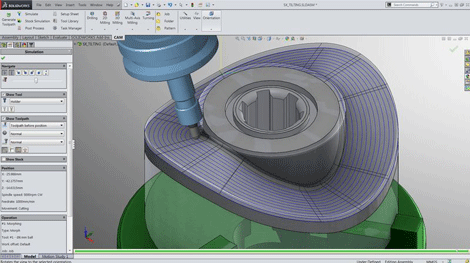

In that time, the company has also released twelve updates with hundreds of new features and enhancements. These enhancements allow users to turn their models and assemblies into machined parts, all within a fully integrated design to manufacturing workflow.

Among the new features is support for the latest Intel Xeon Processors and high-end workstations, like the HP Z840 Workstation, configurable up to 36 total processor cores in one system.

This will allow HSMWorks 2015 to take advantage of the computing power to speed toolpath calculation and post processing times; making it easier to accommodate last minute engineering changes and get CNC programs to the shop floor faster.

Significant updates include Adaptive Clearing, the product’s high-efficiency roughing technology, reducing valuable cycle time from machining jobs by taking advantage of efficient toolpath motion that maintains constant cutter engagement during material removal.

The updated Adaptive Roughing feature also now includes taper support for helical ramps, enhanced stay-down linking and optimised z-level transitioning, which directly contribute to reduced cycle times and more efficient operation on the machine.

Stock simulation has been updated with improved performance in 3D mode, important for customers in the mold/die industry and those who frequently work with large models with 3D and sculpted surfaces.

“This new release is a great example of our ongoing commitment to our customers, regardless of which CAD system they use,” said Robert “Buzz” Kross, senior vice president at Autodesk.

“The feedback from users tells us HSMWorks is valued for its integration, ease-of-use and performance. This release takes the software even further with innovative new updates and features.”

To download a free trial please visit here.