The wire’s been abuzz since yesterday since HP and Stratasys announced a partnership, with many seeing this as the long-overdue point where the 3d printing world jumps off and really becomes mainstream. So, let’s take a look at the announcement, then make a few judgement called on what it means for both companies, why it’s happened and what it means. First, the announcement:

Stratasys, the leading manufacturer of 3D printers and 3D production systems, today announced it has signed a definitive agreement with HP for Stratasys to manufacture an HP-branded 3D printer. Used by product designers and architects, Stratasys 3D printers create three-dimensional plastic models directly from 3D digital designs.

Under the terms of the agreement, Stratasys will develop and manufacture for HP an exclusive line of 3D printers based on Stratasys’ patented Fused Deposition Modeling (FDM) technology. HP will begin a phased rollout of the 3D printers in the mechanical design (MCAD) market in selected countries later this year, with the right to extend distribution globally.

“We believe the time is right for 3D printing to become mainstream,” said Stratasys Chairman and CEO Scott Crump. “We also believe that HP’s unmatched sales and distribution capabilities and Stratasys FDM technology is the right combination to achieve broader 3D printer usage worldwide. HP has made a similar move in this market before, capturing a dominant position in large-format 2D printers. Together we hope to repeat this success with 3D printers.”

“There are millions of 3D designers using 2D printers who are ready to bring their designs to life in 3D,” said Santiago Morera, vice president and general manager of HP’s Large Format Printing Business. “Stratasys FDM technology is the ideal platform for HP to enter the 3D MCAD printing market and begin to capitalize on this untapped opportunity.”

HP’s Graphic Solutions Business – part of the company’s $24 billion Imaging and Printing Group – will execute the distribution agreement. HP is a leading provider of Designjet and Scitex large-format printing solutions, Indigo digital solutions for commercial and industrial printing, inkjet high-speed production solutions and specialty printing systems.

For me, the key part of this announcement is this “Stratasys will develop and manufacture for HP an exclusive line of 3D printers based on Stratasys’ patented Fused Deposition Modeling (FDM) technology.” There have been link ups between traditional RP vendors in the past. see the merger between Contex, a scanning device manufacturer and Z Corp. And of course, Sony were active in the stereolithography market for quite sometime but that seems to have died a death of late.

So, this is the first time that there’s been a rapid prototyping link up between a traditional player and a major manufacturing force – and they don’t come more major that Hewlett Packard. What’s interesting here is that it appears that HP will not be badging Stratasys’ products (as Contex do with Z Corp products), but Stratasys will be developing new line of products – and that is huge. While Stratasys’ Dimension Printing business line has been shifting major units of its lower-cost products for a good decade or so and has been a market leader, running ahead of the pack with Z Corporation for some time.

Why Now?

Many have been talking about mainstream rapid prototyping for many years, but until very recent, it was still restricted to the world of design, engineering and manufacturing. the reasons for that were down to two key factors as far as I could see. The major is cost. RP machines have, until recently, been very very expensive. From the early days of stereolithography with 3D Systems and EOS, through the introduction of Sintering-based process, the equipment was costly (mostly because it uses laser optics based methods). FDM changed the game, as it uses an molten extrusion of filament to build parts, rather than costly lasers and optics. Z Corp offered lower cost products for the same reason. Lower cost parts, process and materials meant they could offer lower cost machines.

The other reason is patents. The RP world has been patent mad – to qualify that statement, the various manufacturers have been rabid about protecting their intellectual property to the point where it’s nearly killed some of the bigger vendors by distracting from product development and real innovation.

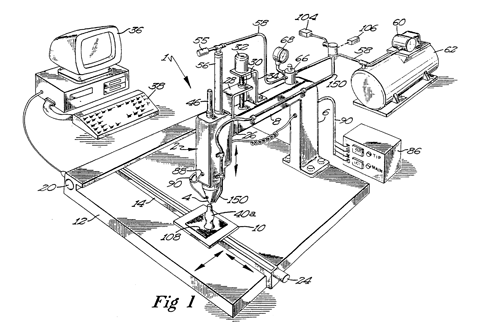

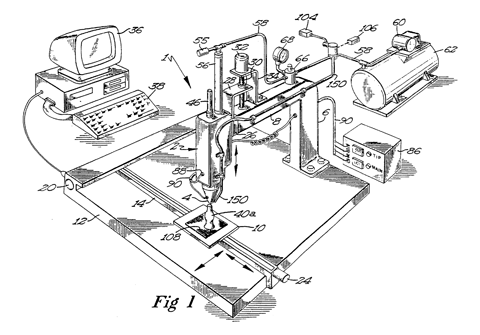

But patents expire and many of the original and highly fundamental patents have now started to expire. One of the key patents is US Patent number 5121329. US patents have a lifespan of 20 years. As you’ll see, this fundamental patent expired last October. Without that fundamental protection, Stratasys have gone past the point of no return and despite of a heavy schedule of filing new patents, without this core patent, there would be interesting times. But alongside these commercial shenanigans, there’s an interesting analogy with the RP world and HP, who famously started in a garage.

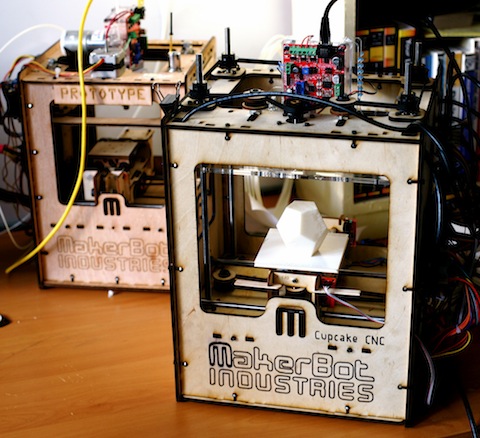

The last few years have seen a similar movement in the RP world. Much of these were kicked started by Adrian Bowyer at the University of Bath and his RepRap project with developed over the course of a number of years, a fully open source rapid prototyping machine. this work has exploded in the last few years and spured many commerical endevours to build businesses of the back of it – perhaps the most famous is the MakerBot . These products offered dramatically cheaper alternatives to traditional vendor’s offerings (often by a factor of 10x cheaper or more) BUT, you’ll notice that they also use the extruded deposition method of construction.

So, with those in the ‘garage’ (if you call MakerBot shifting 150+ units a month a garage business) jumping all over their turf with cheap (and I mean really cheap) alternatives and patent expiration, the time is perfect for a link up with an organisation that has the ability to shift serious volume of products. With volume comes the ability to reduce cost of manufacture and that for me is another key factor.

This is the dirty little secret of the RP world. Unless you’re talking laser optics-based systems, many 3D printing machines are pretty basic mechanical devices. Z Corp uses powder, ink, binding agent and off the shelf inkjet print heads to create models. FDM uses plastic filament, a heated tip to do the same. All have some form of movement mechanism, but these are height enabled version of the same mechanisms that have been around in dramatically lower cost machines for decades.

With HPs involvement the potential for Stratasys to shift dramatically larger volumes at lower costs means even cheaper machines and that in turn means more volume. The cycle is endless. According to Ralph Grabowski’s blog, Stratasys admitted that they’d only be able to produce 5,000 units per year. While this initial agreement sees Stratasys building the machines for HP, my prediction is that HP will bring its global manufacturing expertise to play if things take off. And that’s when it’ll get crazy.

Why Stratasys?

The answer is simple. There are many different rapid prototyping methods. SLA uses resins and lasers. Sintering uses lasers and powder. Z corp uses powder and printed binder. The list goes on. And on.

What links these is that they all have at least one advantage – of mess or of complexity/cost. Z corporation is a relatively cheap process in comparison to SLA, but the powder nature of material means that it’s not ideal for home or office, widespread use. Stratasys’ FDM process is perhaps the cleanest of them all.

I had this part built when we tried out the uPrint machine when it launched – data straight from SolidWorks built in a couple of hours. And yes, you can jump on it and it won’t break.

It also builds very very tough parts. While the material is often referred to as being a production intent material (such as ABS), the product method and the production process means that you’ll never get the same mechanical characteristics as injection moulded plastic – but it’s helluva lot tougher than most RP parts and the company has built its reputation on that fact alone.

Questions?

The deal raises many questions. When? Later this year. Where? For once, the Europeans will get first go at it, with Germany, France, Italy, UK, and Spain getting the first dibs (I’d guess there’s either some patent licensing/commerical agreements, perhaps with resellers stopping the US getting in on the act at launch too. How much? God knows. My prediction is that these will be much lower than the uPrint machine (it’s currently $14,900) – my guess around about the $6K to $8K mark.

If HP use their printing experience, perhaps they’ll even discount it further and make the cash back on selling filament materials. More technical questions mostly relate to materials – both build and the question of supports and their removal. At present, Stratasys’ machines all use support material that in most cases is water soluble. I wonder how this will work out in more commercial product. The likes of the MakerBot do without it. Can the HP FDM do without it too and just produce parts, straight off the machine? Also, how will the material be delivered? Stratasys have cartridge based material deployment at present, but is that ready for the big time? Also, what about blocked nozzles and such?

Alongside these questions, there are also questions relating the industry as a whole. Other vendors are going to have to look at their business models and product/consumable prices. Service providers might be affected also if these things proliferate. and of course, there’s also a whole industry waiting in the wings to build around these types of products. If you have commmon place 3D printers, then people are going to need parts to build. Someone will build a business around providing spare part models for common appliances – you buy, you download, you print. That raises the question of liability if that part fails (something that’s been discussed at the ReBang blog.

But let’s not get carried away with the negativity. This is a huge week for the rapid prototyping world. Perhaps it’s time that the promise of the last 30 years comes true and that we can all afford to have a 3D printer in the home, or at least in the office. This might all be pure speculation and I’m sure I got a few details wrong, but it’s exciting times and we’ll find out what’s going on in the coming few months.Game on.