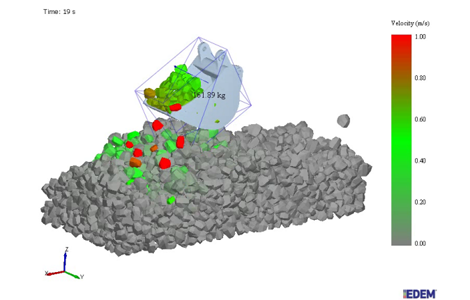

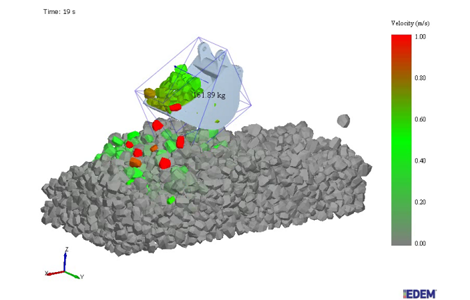

Excavator simulation for rock lumps, where EDEM provides realistic data on the mass loaded in the bucket and the force against the bucket

DEM Solutions has announced new EDEM co-simulation solutions with three leading Multi-Body Dynamics (MBD) software packages; MathWorks Simulink, Siemens LMS Virtual.Lab Motion and MSC Adams.

The tools allow manufacturers of heavy equipment to gain better insight into machine-material interaction, such as the capability to model and visualise the dynamics of equipment movement and examine how loads exerted by bulk materials are distributed throughout the mechanical system.

The EDEM-MBD solutions make use of the EDEM Coupling Interface – a programmable interface that enables bi-directional communication between EDEM and other codes.

//www.youtube.com/embed/JQhC4xjLwlo

By regularly exchanging information, the interaction between equipment and material can be more accurately modeled. Testing of design variations is performed virtually and the resulting changes in the material interaction are fed back directly to the model.

“Being able to predict the loads and forces acting on equipment is the key to optimising equipment performance and durability,” said Richard LaRoche, DEM Solutions VP of engineering and software development.

“Without EDEM, design engineers have to rely on ‘rules of thumb’ and guesswork for the forces exerted by bulk material. EDEM-MBD co-simulation enables engineers to look at equipment interaction with different types of materials and different maneuvers with a high level of fidelity.”

DEM Solutions is set to pursues a strategy of integrating EDEM with other CAE tools, so expect to hear more stories along this line in 2015.