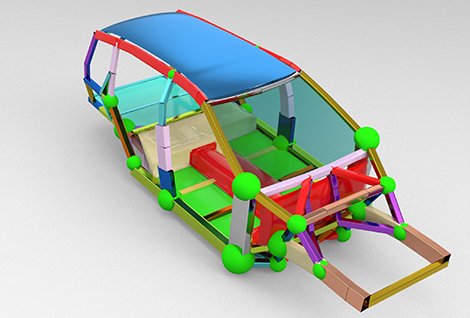

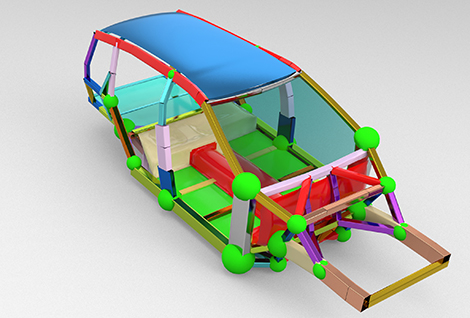

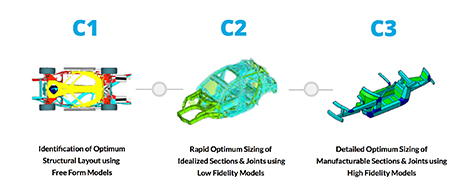

The Ferrari ‘Next Generation’ platform will have gone though the C123 optimisation process, similar to this model, halfway through the process – displaying optimum sizing of sections joints using low fidelity models

Luxury sports car maker, Ferrari, has been working with a team of specialised designers and engineers from Altair to realise the company’s ‘Next Generation’ vehicle platform.

The design will prove the basis of several new flagship vehicle derivatives, reportedly being 15 per cent lighter, while enhancing the performance of crash, NVH and other critical attributes by over 20 percent.

Altair’s team worked on-site at Ferrari’s vehicle development centre in Italy, alongside the Prancing Horse’s own design, engineering and manufacturing teams, to enable Altair’s ‘Concept Optimization Driven Process’ – C123 – driven by its HyperWorks simulation technologies.

The C123 process not only optimises layouts and structures of the concept, but suggests the manufacturable sections

Maximilian Szwaj, Ferrari’s director of innovation and BIW development, stated: “It was important for Altair to supply both CAD and CAE expertise to facilitate tight integration particularly when packaging ideas and manufacturing process are so fluid.

“The speed of the optimisation processes deployed were able to control the weight whilst achieving the demanding structural targets as new packaging changes were introduced.

“For Ferrari, the Next Generation platform is a significant engineering achievement.”

The announcement signifies the relationship that the two companies have enjoyed since they began working together over a decade ago.

“I love the Next Generation architecture, it has an organic nature, with the structure flowing smoothly from sections to joints,” announced Dr Royston Jones, Altair ProductDesign exec VP european operations and global CTO.

“It’s an outcome of a massive deployment of structural optimisation defining optimum material layout resulting in outstanding weight/performance characteristics. I believe it truly warrants the title of ‘Next Generation’ and importantly, repays Ferrari’s trust.”

“As an innovation strategy, Ferrari encourages ideas from everywhere and our new design processes were able to rapidly assess the majority of ideas.”