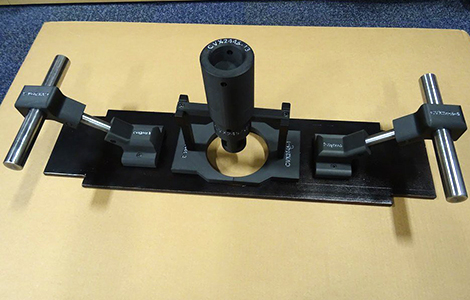

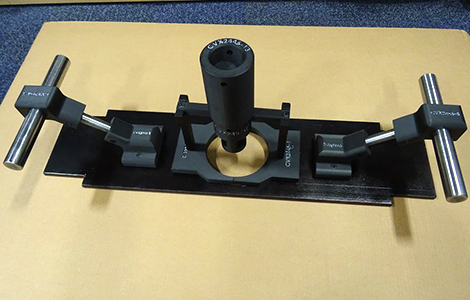

Prototype tooling done in Markforged’s Onyx material

Dunlop’s Systems and Components division has spoken about its move to using 3D printed tooling and prototype parts to aid the development of the next generation of electric vehicles.

Based in Coventry, the facility’s main output is air suspension systems, mostly for trains and heavy machinery, and with the aid of a new Markforged desktop 3D printer it has been producing fixtures to hold parts in place while going through the process of hydraulic crimping.

Original tooling was made from nylon, but hot summer weather caused the nylon workholding to warp, prompting the team at Dunlop to print a replacement fixture using Markforged’s Onyx material.

This method uncovered new timesavings – having previously spent two-to-three weeks on average waiting on parts – and now the company’s tooling is waiting for their respective parts to arrive, instead of the other way around.

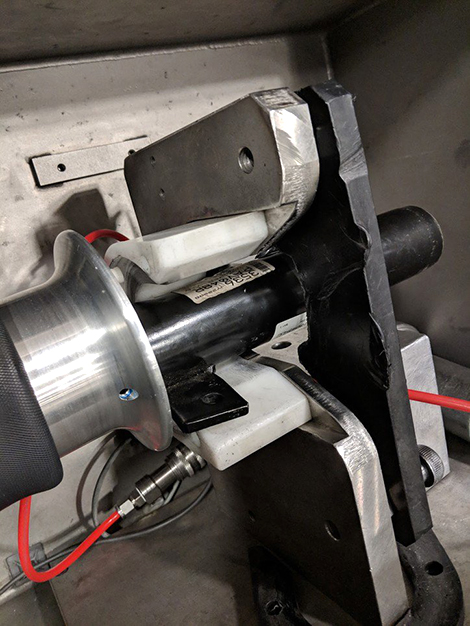

Prototype tooling for a new electric vehicle design

“Our department’s almost got bragging rights because we can now say that we don’t hold up any program. If you want something done, we can now print it within a couple of days. So we’re not holding anyone up,” said production and engineering manager Mark Statham.

It is estimated by the team at Dunlop that it will save £40,000 each year by using its Markforged 3D printer for such projects.

The printer is currently being utilised to print custom tooling for a beta version of a new electric vehicle. The company had previously spent a significant amount of money on the prototype tooling for the car, and have saved thousands of pounds just by using their Markforged printer instead of outsourcing it.

One prototype piston part, for example, would usually cost the team about £500 to fabricate, but now costs £15 to print.

“Since we’ve had it, we’ve never looked back,” adds Statham, “Should have bought it earlier to be honest.”