https://giphy.com/embed/5qFBXUtWtp8HWzsGPd

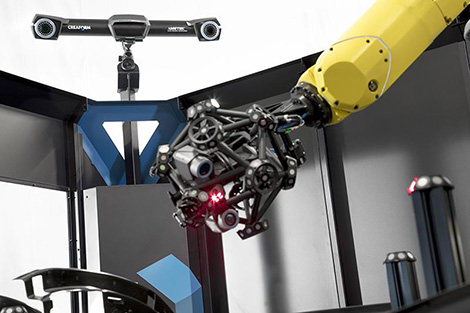

Billed as an off-the-shelf, fully integrated automated inspection solution as an alternative to CMMs in sheet metal, casting and composites, Creaform’s Cube-R should get some attention from big part suppliers.

The scanner extends the capabilities of Creaform’s MetraScan 3D for the dimensional measurement of parts ranging from 1- to 3-metres, with metrology-grade volumetric accuracy on the shop-floor.

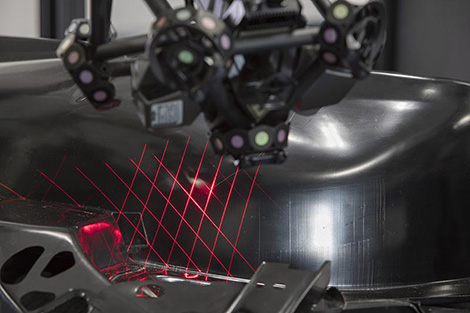

The Cube-R looks to deliver both speed and volumetric accuracy over conventional systems, maximizing production cycle and throughput by offering a simultaneous operation of data acquisition and analysis in a continuous and uninterrupted measurement flow.

Capable of performing inspections of several hundred parts a day, the Cube-R offers automatic field calibration procedure – reducing accuracy drift over time and allowing continuous operation – while also working on dark or reflective parts with complex geometry.

The system fits into a fully enclosed 4.1 x 4.1 x 3.1m turnkey solution with a flexible shop-floor configuration.

“Quality control managers are looking for integrated solutions that enable the detection of assembly problems earlier in the manufacturing process, all while reducing waste and down time to ensure better productivity and higher product quality,” says Creaform product manager Jérôme-Alexandre Lavoie.

“The Cube-R was designed with that in mind. It is the latest addition to our R-Series automated inspection solutions, which also include technology integration for clients looking for customised dimensional measurement solutions.”