A May update for Fusion 360 has been billed by the team behind it as one of the biggest in a long while, and packs in a wide variety of new features and upgrades for the CAD package and its extensions.

Design

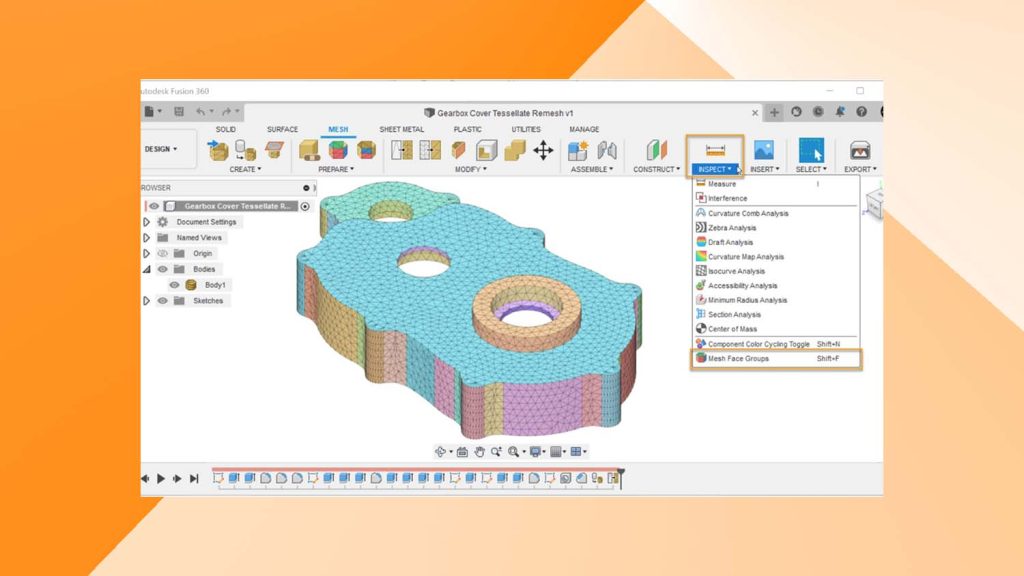

A new mesh face group Display Toggle command is available in the Design workspace [Main Image], letting users easily change the view style of mesh bodies to see which triangles make up each face group. These can now also used in the Manufacturing workspace while creating support structures for additive workflows. The coloured display can be turned on or off depending on what you are focusing on, and the new toggle and keyboard shortcut should help users flip to the wanted setting much faster.

Rib options have been added to the Boss command. This includes a preview of what the rib will look like, default presets, improvements to the Boss for screw connection, rib draft angle and fillet option.

In the Product Design Extension, Snap-fit has been given a better preview with transparency with section view, new selectors to select/deselect bodies, as well as having a Radius Hook Root.

The Replace Component command introduced earlier in 2022 now supports replacing external components that are part of a pattern in Parametric Modelling mode. Select any instance of the component, right-click, then select Replace Component. Navigate to and select the new external component you want to use, and all the instances in the pattern update at once.

Additive Manufacturing

To begin with, five new additive materials have been added into the Fusion 360 Material Library, making this an exciting release for users of EOS and Formlabs 3D printers.

The Autodesk material testing labs in Australia have done the due diligence on these materials, which are now available in the Design, Simulation, and General Design workspace. They can be directly assigned to a design so that it accurately represents what parts are made of, as well as the properties that come with these materials.

They include:

PA11 – Nylon HP 11-30 (with EOS P 396 3D printer)

PA12 – Nylon PA 603-CF (with EOS P 3D printer)

PEKK – Polyetherketoneketone Reinforced With Carbon Fibers – HT-23 (with EOS P 810 3D printer)

Nylon 12 (with Formlabs Fuse 1 3D printer)

Tough 2000 (with Formlabs SLA 3D printer)

Additive Simulation is now a part of the Additive Build Extension, meaning users no longer need to gain access to two separate extensions to fully benefit from Fusion 360’s metal additive capabilities – of which more machines have been added. SLM Solutions: SLM NXG XII 600, Xact Metal: XM200G and DMG MORI: LASERTEC 30 SLM. These machines can be downloaded from Fusion’s online machine library, or can be accessed directly within Fusion 360 if users have the following technology preview enabled.

Part orientation in the build chamber gets new common sense added to the Automatic Orientation function available within the Additive tab. A new Ranking criterion in the May 2022 update, “Center of Gravity Height”, will rank the outcomes of an automatic orientation study, with lowest centre of gravity, above other orientations.

The Fusion 360 team has also modified the System defaults for the Automatic orientation dialog, so that the top ranked orientation outcomes you get after running an orientation study is the desired outcome for printing parts with an FFF printer. This change to the system defaults eliminated the need for a duplicate template to exist in the template library, removing the “Automatic Orientation -FFF” template from the installer.

There are new Additive Support Templates in Template Library, the ability to select mesh face groups while creating supports, and you can now taper the angle of padded bar supports. Never say that Fusion 360 doesn’t offer support!

The online machine library now also hosts Print Settings, which among other things, has also added new print settings for PETG filament so you can 3D print with a desktop FDM 3D printer, as well as several print settings for industrial Renishaw systems.

Users of desktop FDM 3D printers also get the ability to pause prints to insert items such as magnets by simply typing in the layer number(s) you wish to interact with your print during manufacturing.

A new filament change option to print with multiple colors on a single extruder Prusa printer, for example, should add a bit of variation.\

Electronics

It wouldn’t be an update of Fusion 360 without PCB design updates, and the May update is no different. To ensure PCB manufacturability, certain design rules and regulations (such as clearance between traces, trace width and annular rings) need to be considered during the PCB design process. Before beginning the trace design process, the first step is to determine how many signal layers your board will need – i.e. your layer stack.

The most common layer stack consists of two or four layers, but Fusion 360 can handle up to 16 signal layers.

Now users can specify the material (and material properties) used for all your PCB layers such as surface finish, the conductive weight property for your signal layers, and the type of dielectric material (prepreg or core) used to separate each layer. PCBs that require high speed communication, such as DDR, will use very different layer stack properties than a high-voltage power supply design. With this implementation, you’ll be able to capture and communicate your design intent to a manufacturer more accurately.

Additionally there’s support for slotted pads (a user request), improved handling of panels, and a new Radial Template added to the Library Editor.

Fusion 360 includes numerous libraries created its team of librarians as well as components added by partners such as TE Connectivity, Wurth electronics, and many others. If what you’re looking for is not available, making a component from scratch with Fusion 360 Electronics is an easy option. The library editor includes a package generator that utilises templates to streamline the component creation process using mechanical specifications.

The May update for Fusion 360 also adds Ultra Librarian, an add-in for Fusion 360 that provides access to a rich repository of design ready electronic components.

Ultra-Librarian has a significant amount of electronic CAD components with schematic symbols, footprints along with 3D Models. In addition, the component description also includes links to the data sheets and the product page. Autodesk says that with this new add-in, users can directly import the parts required for a design into the library that can be accessed from Fusion 360 Library, Schematic & PCB workspaces.

Updated icons are to be found following what Autodesk says is a comprehensive update to all of the electronics toolsets with the ambition of making commands ‘more visually representative and distinct’, which should improve productivity and ease of learning.

Generative Design & Simulation

Generative Design sees a maturation of Fusion 360s Experimental Generative Solvers and Features Preview, adding an additional outcome to the generation process based on new solver technology that the team has been working on that should bring improved performance and improved scalability.

Users will now see an additional outcome in setups that contain fixed, pinned, or frictionless constraints and force, pressure, moment, and bearing load types.

New Auxiliary Views have been added to Drawings in Fusion 360, meaning that the detailing of features on faces at an angle just got a lot easier. Auxiliary views let users project a view parallel or perpendicular to a face or edge. Elsewhere a new arc length dimension tool has been added, letting users create dimensions that display the true length of arcs.

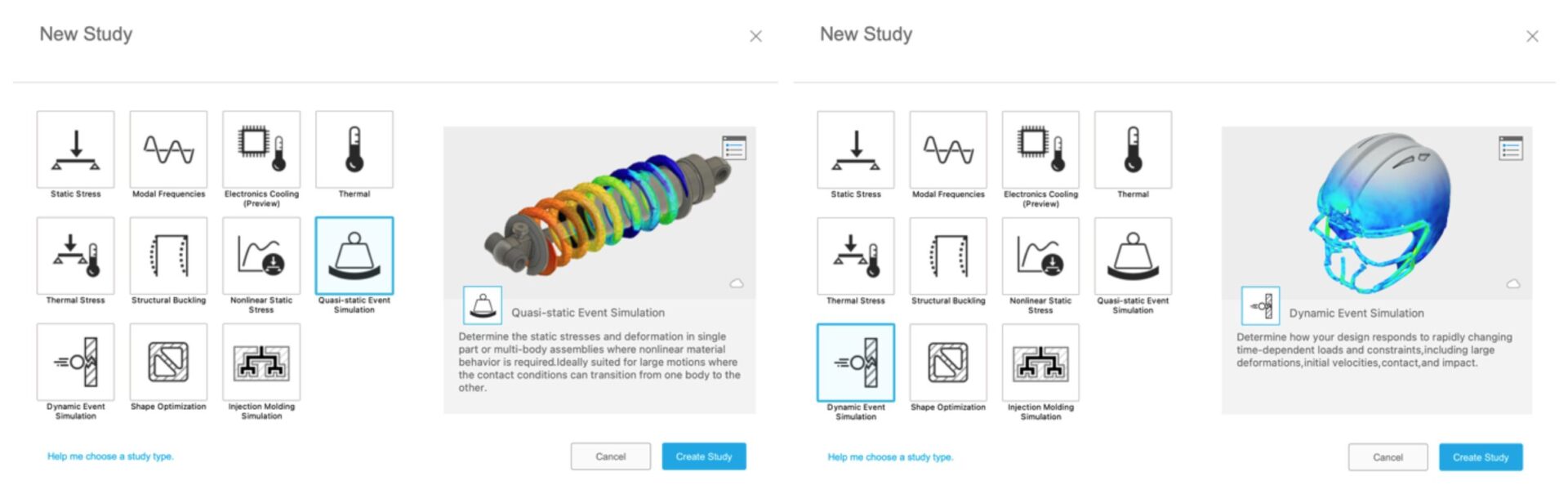

Simulation updates in Fusion 360 have seen features like quasi-static simulation study made easier to discover – this analysis set-up is useful for large deformation and contact problems that involve large sliding motions and friction, or Nonlinear material behaviour such as large plastic deformations.

There are also two new result visualisations for Contact Force and Contact Pressures along with an added enhancement where the user can now get Reactions data for Force and Moment at Contact locations as well. Autodesk says that these Reaction values can then be used as a reference when setting up a Generative Design Study.

Manufacturing

In the Manufacturing toolset, May sees the beginning of the end for the Legacy Tool Library, moving the Tool Library out from behind public feature flag and making it the default experience for all Fusion 360 manufacturing users. Its a big release for Manufacturing features, so here’s a short video that should help sum up all the key info:

As ever, there’s a huge number of updates and marginal gains in this release, and the best way to dig deeper into all these new features is via the Autodesk Fusion 360 Blog produced by the team behind the software.