If you’ve developed a kick ass 3D printer that not only builds in killer nylon mixed with chopped carbon fibre, but also lets you add in layers of single strand fibres, what do you do next?

Well, for Markforged, it seems that the answer is GO BIG.

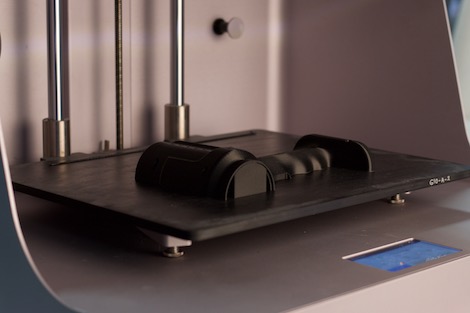

Launched today, After the success it has seen with its Mark Two 3D printer, Markforged has launched the next generation of its product range in the form of the Mark X.

The Mark X takes the core filament and fibre capabilities of its existing products and builds this is a large capacity, production capable machine. The Mark X features a 330 x 250 x 200mm (that’s 12 x 10 x 8 inches for you imperial perverts) build chamber.

For reference, this is over two and a half times that of the Mark Two and the print resolution is 50 micron. This build chamber, 3D print aficionados will realised, brings it directly into competition with Stratasys’ entry level Fortus 380mc machines. Namely, it’s big. Very big.

It takes advantage of the same material combination of Mark Two, meaning either Nylon or Onyx (a black nylon mixed with chopped, short strand carbon fibre) alongside single strand carbon fibre, glass-fibre and Kevlar.

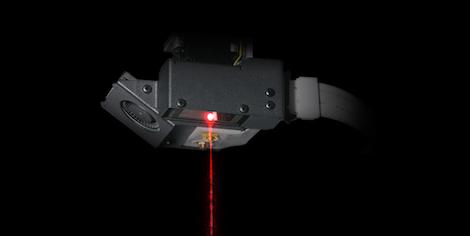

Alongside the greater build capacity and higher resolution, the Mark X also sees the introduction of in process inspection – with the integration of a laser micrometer into the build head.

The Mark X now includes in process inspection

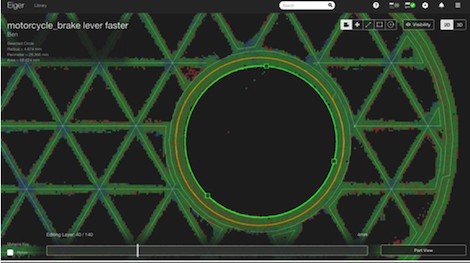

This will allow the machine to inspect each layer (or a user defined number of layers) to check for consistency and to inspect each part’s layer as it’s built or at specified time steps.

This means that parts that don’t meet tolerances can be aborted early – saving you a tonne of time and wasted materials. Eventually lead to closed loop inspection and automated pass/fail indicators once the parts come off the build plate.

Screenshot from Markforged’S Eiger system, showing results from in process inspection

The recommended price for the Mark X is going to be $69,000, featuring a kit to get you up and running. This includes the machine, two build plates, a selection of materials (Onyx, Nylon, Carbon Fibre, Kevlar and both the standard Fibreglass and high temperature glass fibre) and three print nozzles. Of course, with a machine of this size, scale and cost, servicing is going to be a concern for customers – sending this bad boy back to base isn’t going to fly. Markforged are in the process of finalising plans, but it looks like this will be primarily done through trained and certified resellers.

If you’re already a Markforged user, then you’ll get the price of your machine back (without having to trade it in), so it’s worth investigating.

Further reading:

We took a look at the Mark Two over two parts in recent issues – Those reviews are here and here