The new Stratasys J750 technology is set to allow customers to add more than 360,000 different colour shades, plus multiple material properties, to a single 3D print build model.

The latest addition to the Objet Connex multi-colour, multi-material series of 3D Printers, aims to remove time wasted on standard post-printing jobs such as painting and assembly.

The machine is focussed on radicalising the prototyping process, giving designers faster access to an expanded array of colours over previous Polyjet technologies, thanks to a new higher resolution Ricoh printer head with six material jetting nozzles and two for support material.

The new machine is similar in size to the Connex3, but requires a materials handling unit

The new print heads also help aid print speed, with simulated production plastics, like Stratasys’ Digital ABS, reportedly able to be 3D printed in half the time of other Stratasys PolyJet systems.

The Stratasys J750 also helps minimizes downtime associated with material changeovers. Featuring a large, six-material capacity, it keeps the most used resins loaded and ready for printing.

A new streamlined workflow beginning with the all new PolyJet Studio aims to let users choose materials, optimise the build and manage print queues. Assignment of colours, transparencies and rigidity is eased via familiar design controls. Colour textures can be loaded fully intact via VRML files imported from CAD tools.

“With its one-stop realism, the Stratasys J750 is quite simply a game changer,” said Stratasys chief business officer Josh Clamant.

“By combining full colour with multiple materials and a streamlined workflow, it recalibrates the impact of 3D printing in the product development cycle.

“Informed design decisions can be made immediately after the concepting stage. The time saved by eliminating the painting and assembly process can lead to faster product delivery times.”

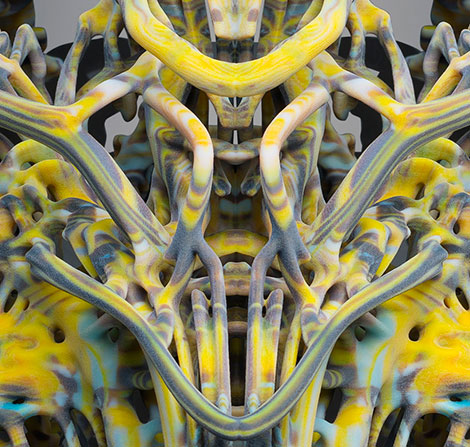

Close up detail of artist Nick Ervinck’s sculpture Wolfram, produced on the J750

Art pushes colour abilities of latest Stratasys 3D printer

Allowing users to add more than 360,000 different colour shades removes the need to paint models, removing the need for post process painting for producing colour prototypes fast.

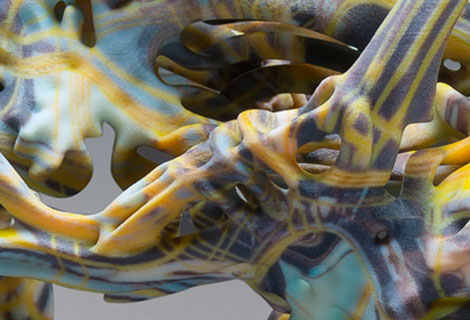

However, it is artist Nick Ervinck’s sculpture, Wolfram, that is already pushing the colour capabilities by combining detailed, unusual forms with colour embedded into the artwork.

“The vibrant colors and intricate details of the piece, such as the central lines representing the figure’s veins, were integral to the sculpture, both in creating a sense of movement and fluidity and in reflecting the traditional cultural styles that inspired the work,” explained Ervinck.

“It would have been impossible to manually transfer this texture onto the sculpture in any other way – it is only with the new Stratasys J750 3D Printer that this first-of-its kind artwork has been made possible.”

The colour palette of previous Stratasys colour 3D prints was limited by comparison, while with the J750 each pixel is a purposefully chosen colour from a massively expanded range primarily aided by the higher resolution Ricoh printer head with its six colour material jetting nozzles.

The 3D printed sculpture in full