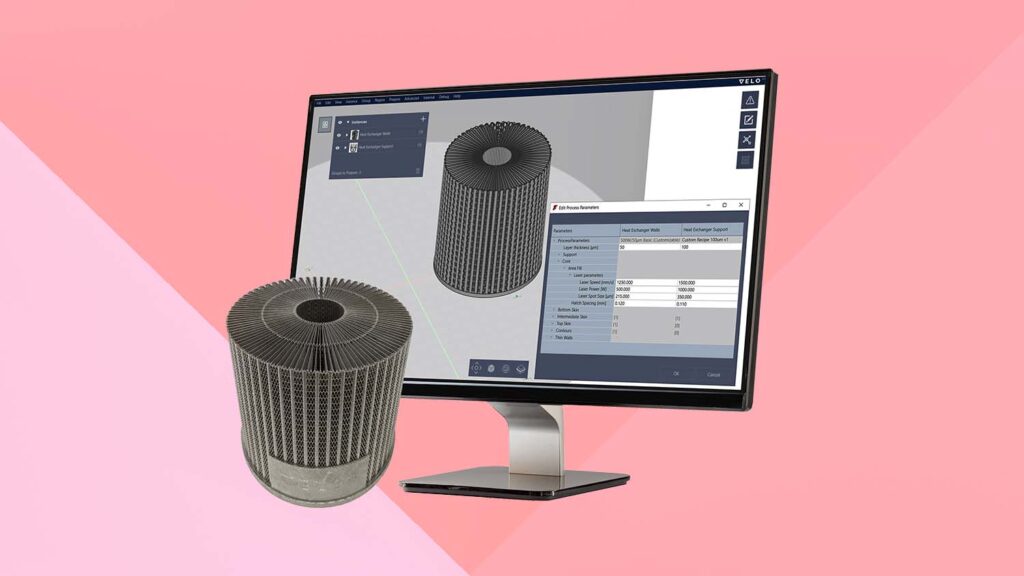

A new feature to Flow 7.0 print preparation software, Developer, offers ‘editor-level access’ for custom control of Velo3D’s metals 3D printing print parameters.

Developer gives access to indepth print parameters, giving increased flexibility and control when using Velo3D 3D printers.

The company says that the feature unlocks full transparency and control of its additive manufacturing process, allowing users to control production, quality and repeatability of their designs.

Users will be able to import proven parameters they have developed, optimise default parameters for specific application needs, and develop parameter sets supporting new material development for novel solutions and specific applications.

Once a part produced using Developer has been qualified, users can scale production.

According to Velo3D CEO Brad Kreger, the company’s mission has always been to provide an additive manufacturing solution that ‘delivers repeatability from machine-to-machine’. Previously, this was done through pre-defined parameters, which had little flexibility.

“When you combine Flow Developer with our ability to produce identical parts using the same print file, we strike the perfect balance between usability, repeatability, and flexibility,” said Kreger.

“This has allowed these early access customers to think outside the box of conventional additive manufacturing to progress beyond their current limitations and realise true production scalability for their parts.”

Prior to its general release, Developer was beta tested by Velo3D customers, including rocket propulsion technology company Ursa Major.

“It can be a challenge to produce repeatable results across different metal 3D printers – even when they’re the same model of printer,” explained Ursa Major additive manufacturing manager Thomas Pomorski, who’s team first transferred parameters from a non-Velo system to a Velo3D Sapphire 3D printer to try and increase the scale of production.

“On our first try, we imported a part with highly complex, sensitive features and achieved incredible results that were within specification. Since then, we’ve accomplished the same process with other parts and in some cases, have been able to reduce print time by nearly 50 per cent without sacrificing accuracy or quality,” he said.