Sintratec has released its first nesting solution software for its SLS 3D printing, with the goal of attaining ‘unprecedented packing density’.

The Swiss manufacturer of SLS 3D printers has produced the software in order for its users to save time and materials when using its Sintratec S2 3D printer.

Sintratec says that with a single click, the imported 3D objects are analysed by its algorithm and optimally placed inside the cylindrical print area of the Sintratec S2 System according to various configurations.

Not only does the Sintratec Nester solve these calculations much faster in direct comparison with previous market leaders, they say, but it also sets new standards in terms of density.

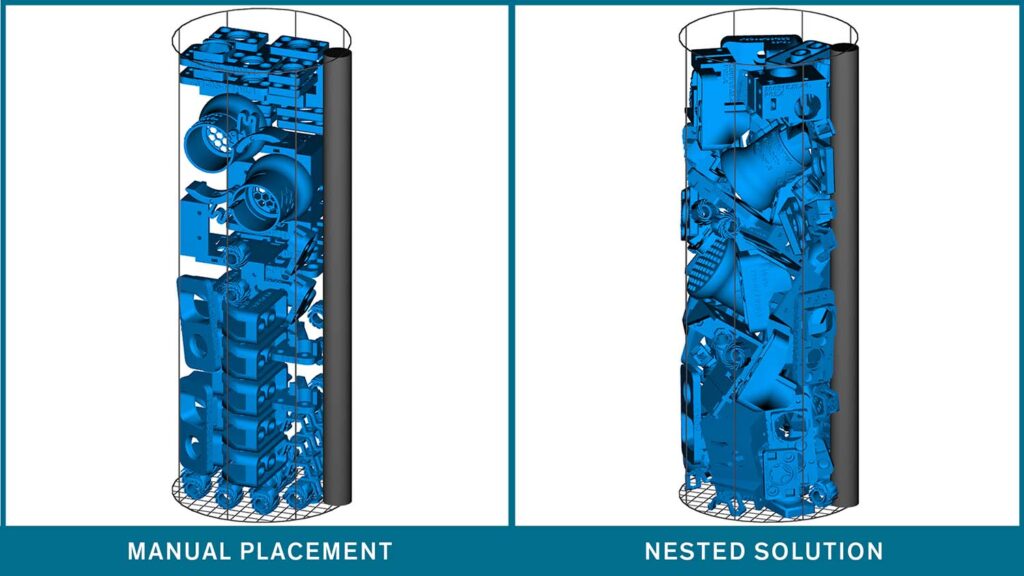

Packing density is a key factor in optimising the throughput of 3D production – especially with Selective Laser Sintering (SLS), which does not require support structures. Depending on geometries, Sintratec says its algorithm achieves up to twice the density of manual placement, thus reducing the required print volume by half.

Nesting 100 print jobs with our Sintratec Nesting Solution is reportedly able to save 50 work hours, 47 kg of powder, and 800 hours of printing time.

The new software is free of charge for the first year to all current and new Sintratec S2 customers.

Sintratec CTO Christian von Burg, said: “With the addition of a 3D nesting function, we are taking our software to the next level. No other program on the market is capable of nesting 3D parts as densely in such a short time as ours.

“The Sintratec Nesting Solution therefore marks a milestone on the path towards efficient additive manufacturing and is a real game changer in the field of selective laser sintering.”