Siemens Mobility’s flagship site, the RRX Rail Service Centre in Dortmund-Eving, Germany, services around 100 trains in the depot every month – a level of throughput that puts pressure on its supply chain.

In response, the RXX is looking to eliminate the need for an inventory of selected spare parts and reduce the manufacturing and delivery time of these parts by up to 95% by taking FDM 3D printing in-house.

“We believe our RRX Rail Service Centre is the most advanced train maintenance centre in the world,” said Siemens Mobility head of additive manufacturing Michael Kuczmik. “Bringing together a range of innovative digital technologies, we can significantly increase the efficiency of our customer’s rail operations.”

According to Kuczmik, the ability to 3D print customised replacement parts on-demand has increased its flexibility to meet customer requirements.

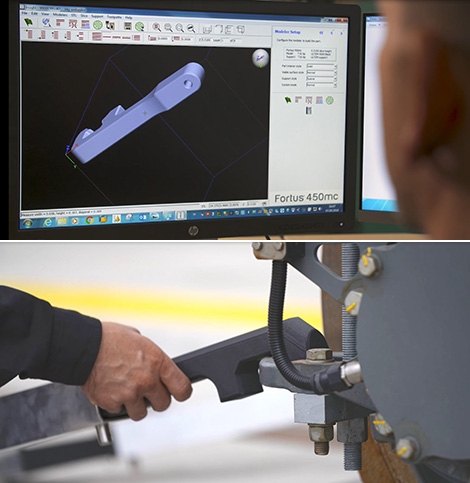

The company invested in a Stratasys Fortus 450mc Production 3D Printer to produce replacement parts and tooling on-demand, while enabling engineers to re-optimise older spare parts for longer life cycles, at reduced costs and in shorter timeframes.

With each train going through maintenance several times a year, and with demands of quality and safety, the RXX team also have to fight through unplanned or last-minute jobs, across a wide range of train models and operators – meaning there’s a lot of customised solutions needed.

One such example is an essential ‘connector’ tool that is used to maintain train bogies (the chassis or framework that carries the wheelset). Tools for this application are notoriously hard to produce via conventional methods, as they have extremely complex shapes and require a high-level of customisation.

In addition, bogies weigh several tonnes, therefore tough and durable materials are required to withstand the significant forces when the vehicle is moving or braking.

The RXX is now using a Fortus 450mc to turnaround one-off tools customised to each bogie in a matter of hours. To meet the demanding material characteristics required, the team is using Stratasys’ industrial-grade Ultem 9085 thermoplastic material.

“The ability to 3D print customized tools and spare parts whenever we need them, with no minimum quantity, has transformed our supply chain. We have reduced our dependency on outsourcing tools via suppliers and reduced cost per part, while also opening up more revenue streams by being able to service more low-volume jobs cost-effectively and efficiently,” concludes Kuczmik.