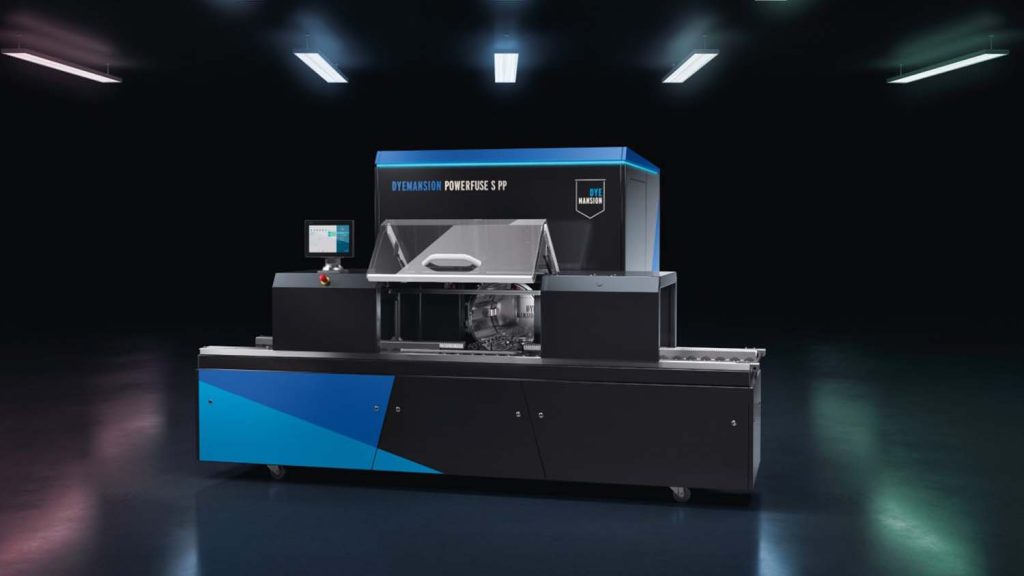

Dyemansion has announced its Powerfuse S PP post processing station for vapour polishing, allowing for 3D printed polypropylene parts to benefit from surface and material improvements.

While the original Powerfuse S model works with all common rigid and flexible materials on the market such as PA, TPU and ULTEM, he new Powerfuse S PP is dedicated for the processing of for polypropylene.

The new machine enables more application possibilities with the use of polypropylene in Additive Manufacturing, and claims to be a more sustainable option through its use of VaporFuse VF44 EcoFluid PP, a ‘100% bio-based and readily biodegradable as well as non-toxic: no PFAS, non-CMR, non-vPvM/PMT’.

A high degree of automation and closed loop circulation with integrated solvent recovery means that this industrial solution should help users attain good cost per part at full production capacity.

Polypropylene is one of the most widely produced plastic globally with advantages due to price, toughness and ductility, as well as chemical resistance, and the Powerfuse S PP has been validated together with all technology providers for PP already, including Stratasys, HP, BASF, EOS, Prodways and more.

Dyemansion has also announced new partnerships with 3D printing vendors Next 3D and HP – with the latter specific to the Jet Fusion 5420W. HP is working closely with post- processing tech company DyeMansion to offer connected post-processing workflows for finishing and colouring white parts produced with the new HP solution.

DyeMansion’s solution is capable of providing a wide range of vibrant colours with high consistency and different finishes depending on application needs.