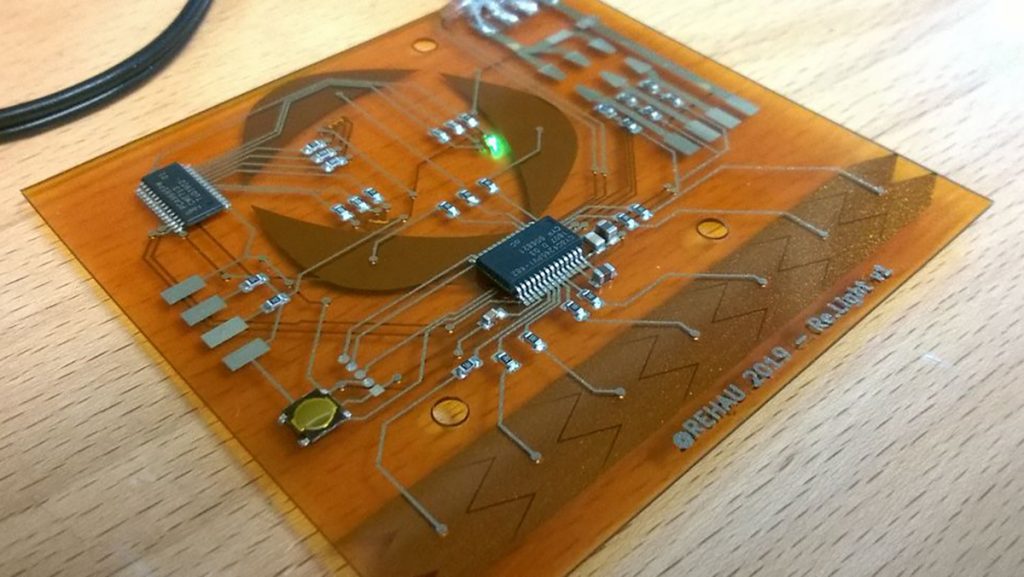

A 3D printed touch sensor produced using Nano Dimension’s technology by Rehau as it looks to innovate consumer products with IoT capability and develop devices with improved performances and efficiencies at a lower cost.

Devised as part of Rehau’s dedicated Electronics into Polymers technology platform, the mission is to make their premium polymer products smarter and increase the value for its customers by seamlessly integrating electronics.

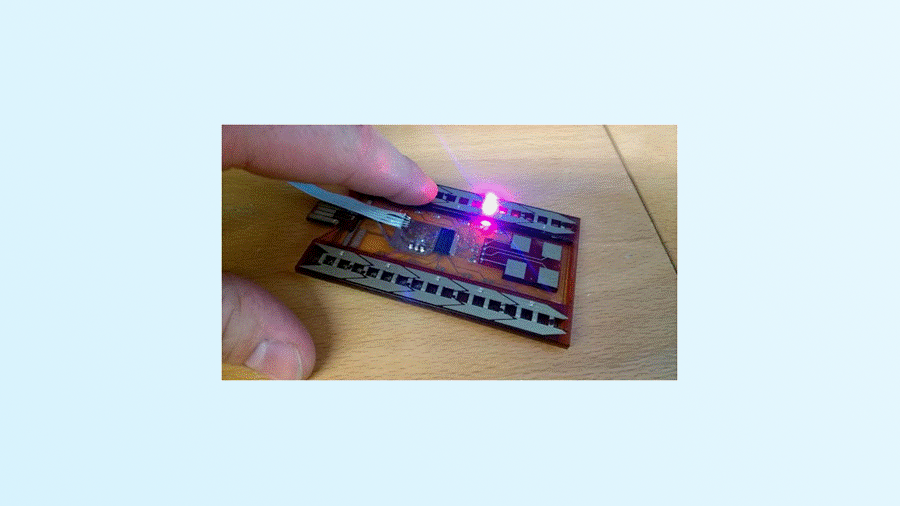

The device allows for polymer products to be transformed into back-lit human-machine-interface surfaces, increasing the part functionality and the convenience for the user, all within a very sleek design.

The 3D printed touch sensor and its electronic circuity was printed as one using the NanoDimension DragonFly LDM, which is capable of producing unique and non-standard shapes for circuitry.

“Rehau is developing improved products for the smart home and IoT environment, and Nano Dimension is providing important technology to help accelerate the availability of promising new applications,” said Dr. Ansgar Niehoff, head of Rehau’s Electronics into Polymers platform.

Dr. Philipp Luchscheider, the Rehau engineer behind the 3D touch sensor design, added, “With the DragonFly LDM we will drive forward Rehau’s Electronics into Polymers strategy to speed up in-house electronics development and find new installation spaces and functions for our products.”

The process proves particularly economical when used for fabricating small batch sizes or a large number of variants.

Rehau is currently running projects in the glazing and automotive sectors, for example, which with the help of the new technology, prototypes can be produced within a few days without having to rely on many tools or external partners.

Nano Dimension EMEA GM Valentin Storz, added, “This gives Rehau the increased design freedom to develop innovative products, quickly and cost effectively.”