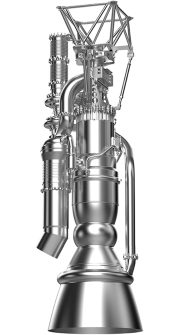

With more than 20 critical components inside the QL-1 rocket engine built on 3D printers, engineers at Space Circling Aerospace Technology not only have new opportunities for innovation, but also more time to test out their bright ideas

When it recently passed a 200-second, long-range hot fire test with flying colours, the QiaoLong-1 (QL-1) rocket engine reached yet another milestone in its impressive development.

The process began back in 2021 at the Liquid Rocket Engine R&D site operated by Space Circling Aerospace Technology in Xi’an, China. In under five years, the company has raised over 100 million yuan ($13.9 million) to take its idea from initial concept to a working 85-ton-class rocket engine.

The results of these latest tests provide a clear demonstration of significant progress, not just in the company’s design of the QL-1, but also in China’s commercial space propulsion ambitions.

The QL-1’s design eliminates the need for an onboard gas generator, allowing for a slimmer form and for five of the engines to be mounted into the 3.35-metre diameter space available on Chinese spacecraft.

Smooth ignition, rapid shutdown and stable, high-efficiency operation throughout testing strongly suggest that the QL-1 is now fast approaching its next stage of development.

Built smart

More than 20 critical components within the QL-1 engine have been designed to be built using metals 3D printing, including thrust chambers, turbopumps, valves and other key structures.

From the earliest stages of its development, Space Circling’s designers kept in mind that traditional manufacturing methods would involve multiple time consuming and costly steps that would in turn hinder them from rapidly iterating on their design.

In their place, additive manufacturing methods have allowed the team to integrate parts, streamline production and significantly accelerate the rocket’s development.

Bright Laser Technologies (BLT), a Xi’an-based 3D printer manufacturer, has been deeply involved right from the start, with 3D printing technology used to efficiently and precisely manufacture key structures that significantly enhance the engine’s overall performance and reliability.

As the primary power source of a rocket engine, the thrust chamber converts the thermal energy of high-temperature, high-pressure combustion gases into kinetic energy to provide propulsion.

In the QL-1 engine, additive manufacturing enables the production of complex internal flow channels within a single build, supporting precise optimisation of propellant pathways and leading to higher combustion efficiency and lower energy losses. The result is improved engine thrust and overall performance.

Other key components, including the thrust chamber nozzle extension, gas generator, thrust chamber body and oxygen inlet were all built using BLT 3D printers. These range from the huge, multilaser BLT-S1000, capable of 1200 x 600 x 1,500mm builds, to the smaller and highly efficient BLT-S450 system.

By using additive methods, Space Circling has sidestepped many challenges associated with fabricating complex internal flow channels, including multiple manufacturing and assembly processes.

The turbopump, which serves as the heart of the QL-1 engine, drives pressurisation and delivers propellant to the combustion chamber, ensuring continuous fuel supply. For this, multiple critical components were produced, including dual-stage impellers, turbine guide vanes, fuel and oxidiser housings.

Time and space

The ability to produce end-use parts using additive manufacturing saw months saved in the development process. For example, the two-stage impeller with dimensions of 340 x 340 x 55mm was built on the BLT-S450 in a single, integrated 3D printing process.

With traditional manufacturing methods, the typical production cycle for this kind of part – from material procurement to final machining – might be expected to exceed three months. This was slashed to 45 days, allowing designers to undertake more testing and achieving a cost saving of approximately 75%.

Space Circling now has ambitions to develop its own reusable launchers using its engines, and with progress this fast on the ground, it can only be a matter of time before take-off is achieved.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here