Materialise has unveiled the 2025 Magics release with nTop implicit geometries integration alongside two next-generation Build Processors and partnerships with Raplas and One Click Metal.

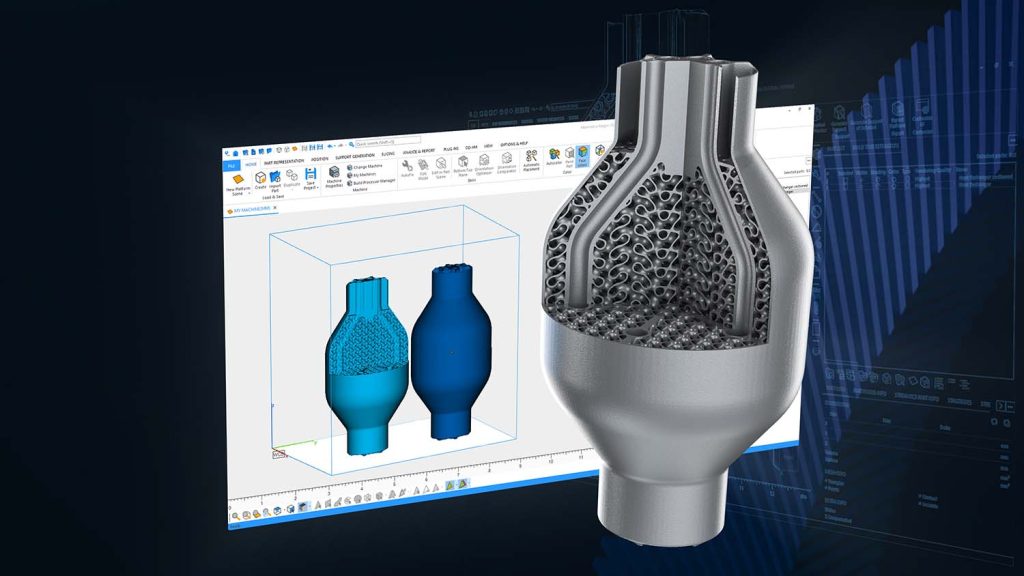

The combined solutions of the new Magics release with nTop implicit geometries is said to overcome traditional 3D printing design challenges by reducing build preparation time from days to seconds while maintaining design precision. This new capability in Magics, combined with Materialise’s next generation of Build Processors promises the printability of complex parts that could not be printed before.

2025 Magics offers solutions for both polymer and metal 3D printing challenges. Magics introduces seamless processing of nTop implicit geometries without the need for mesh conversion, drastically reducing preparation time for complex parts. Paired with the slicing capabilities of Materialise’s next-generation Build Processors, it enables the design and production of parts that could not be printed before due to substantial data and memory requirements.

The new release’s extended BREP processing capability enables users to work with native CAD geometry throughout Magics, ensuring higher part quality, faster performance, and a reduced need for manual fixes. Materialise says that this is ideal for CNC workflows as well as SLS, MJF, and Metal LPBF users, as it streamlines operations by supporting advanced functionalities such as measurements, wall thickness analysis, nesting, and STEP file export for seamless integration into CAM or CAD software.

With post processing accounting for a reported 40–60% of total costs in AM, the latest Magics brings further optimisations for build preparation workflows and support generation, reducing material use and post-processing requirements while maintaining high-quality output.

Designed for series production and prototyping, a new Replace Part & Transfer Support tool facilitates design interactions more easily for NPI and product improvements by transferring support when using the Replace Part function, reducing repetitive work, human error, and lead times.

Supports can be reduced in complex areas with self-supporting volumes, simplifying removal and reducing post-processing efforts. Designed for LPBF, it also benefits other technologies, enabling higher-quality parts with fewer supports.

Magics’ new release also includes several functional updates to simplify the user experience and significant rendering and memory usage optimisations for more efficient, responsive workflows. Materialise says it delivers up to 40 per cent less video memory usage for marked mesh parts and accelerated operations like Extrude (70%) and Perforator (50%). The new Magics release will be commercially available in May 2025.

“As additive manufacturing transitions from a niche technology to a cornerstone of modern manufacturing, the need for intelligent, integrated software is more critical than ever,” said Udo Eberlein, vice president of software at Materialise.

“We are listening closely to the demands of the market and evolving our software portfolio into an integrated range of solutions that work together with other manufacturing tools. By addressing challenges such as cost, scalability, and precision, we are laying the foundation for seamless workflows that connect additive manufacturing to broader production ecosystems.”

Focusing on AM scalability, Raplas and Materialise announce the Raplas next-generation Build Processor for series production in resin-based additive manufacturing, demonstrating a reported 30-40 per cent increase in printing speed, as well as enhanced part quality and reduced post-processing requirement. Materialise has also announced a Build Processor integration with One Click Metal to support the rapid growth of the mid-market 3D printing sector.

“Materialise’s strategy is to enable the next generation of additive manufacturing by combining advanced software with diverse hardware platforms. Collaborations with Raplas and One Click Metal and the launch of the 2025 Magics release reflect our commitment to supporting the full spectrum of AM production. These solutions empower customers to save time, reduce risks, and lower costs, supporting successful AM builds from start to finish,” stated Bryan Crutchfield, VP and GM Materialise North America.