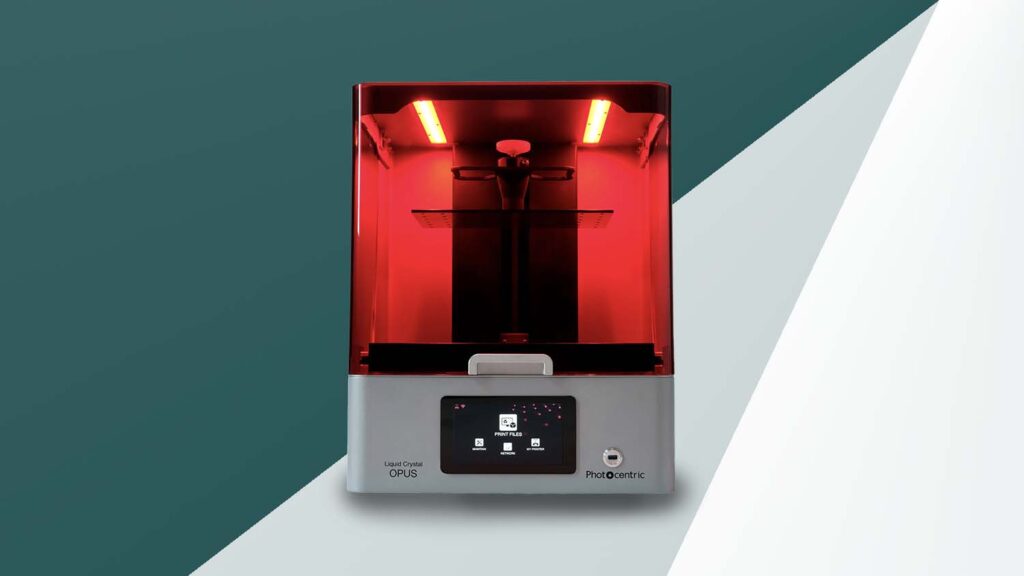

Photocentric has launched the LC Opus 3D Printer, its latest desktop system to utilise LCD light stereolithography for fast curing and low running costs.

Using a 4k 14 inch monochrome LCD screen to cure a wide range of resins, the LC Opus features 310 x 174 x 220mm build volume, and is capable of print layer thickness of 25, 50 and 100μm (resin dependent).

Photocentric has optimised the LC Opus’ light distribution for a repeatable, uniform cure, that when coupled with the 3D printer’s aluminium construction, Trinamic motor drivers and new resin vat design (which includes a self-cleaning mode) should allow it to produce accurate parts.

The Peterborough, UK-based company states that the LC Opus is ready to go ‘out of the box’, with the machine pre-calibrated in the factory, with the included Photocentric Studio software making it suitable for experienced and new users.

Some eye-catching details of the new 3D printer include its interchangeable build platforms that remove the need to re-calibrate for each use; the purpose built 7 inch display, as well as Photocentric’s patented ‘Vat-Lift’ peel release technology.

“We wanted to build a versatile printer that was easy to use and delivered great performance and I believe that we have achieved this,” said Photocentric sales director Sally Tipping.

“It provides customers with a speedy, simple and versatile solution that is equally at home in a dental laboratory as it is in an engineering workshop. Its intuitive and simple operation makes LC Opus perfect for both beginners and experienced users alike across a broad range of applications.

“With its fast cure speed, low running costs and impressive build volume, LC Opus is an excellent all-rounder.”