Hänssler Group has revealed its recent path to qualifying more parts for end use, using Ultimaker S5 3D printers and Kimya’s specialist ABS-ESD filament to produce highly accurate sealant parts with with anti-electrostatic properties.

The German company has over 30 years of experience in producing industrial products such as seals and O-rings, having traditionally CNC machined the parts and more recently explored additive manufacturing processes.

Its most recent parts, 300 seals, were designed to be integrated within an existing production line, to provide thermal protection between two components within a machine.

Surface defects impact ESD performance, which would inevitably alter the dissipation of charges. To get past this, Hänssler’s parts had to be reproducible for both ESD behaviour and dimensional accuracy, in addition to meeting visual and integrity requirements.

Filament diameter is known to have a remarkable effect on ESD behaviour reproducibility. The narrow dispersion of 2.84 mm ± 0.0062 mm (99.999936% confidence interval) in filament diameter of Kimya ABS-ESD enabled flawless extrusion volumes and height layer-stacking, prior to melt solidification.

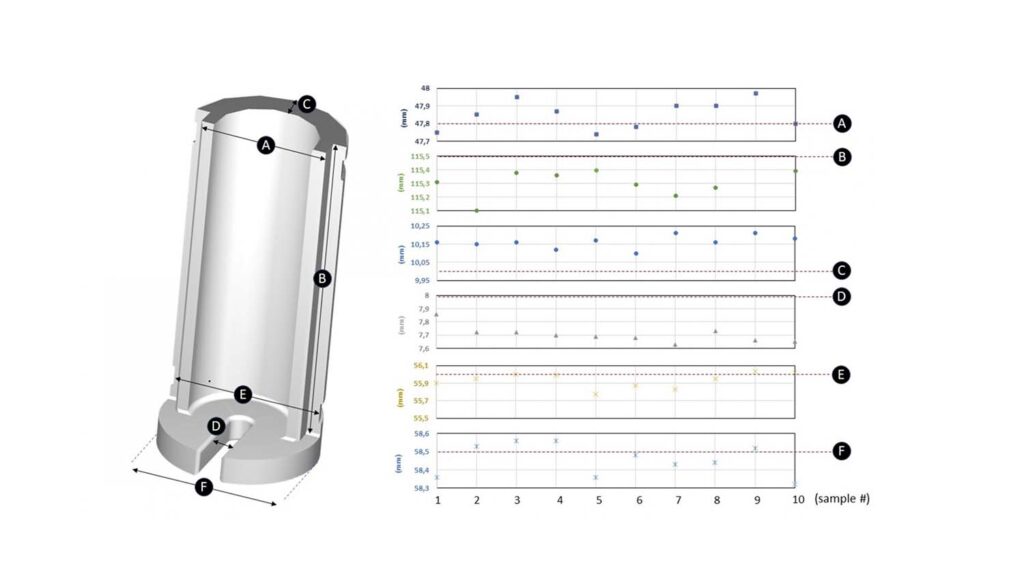

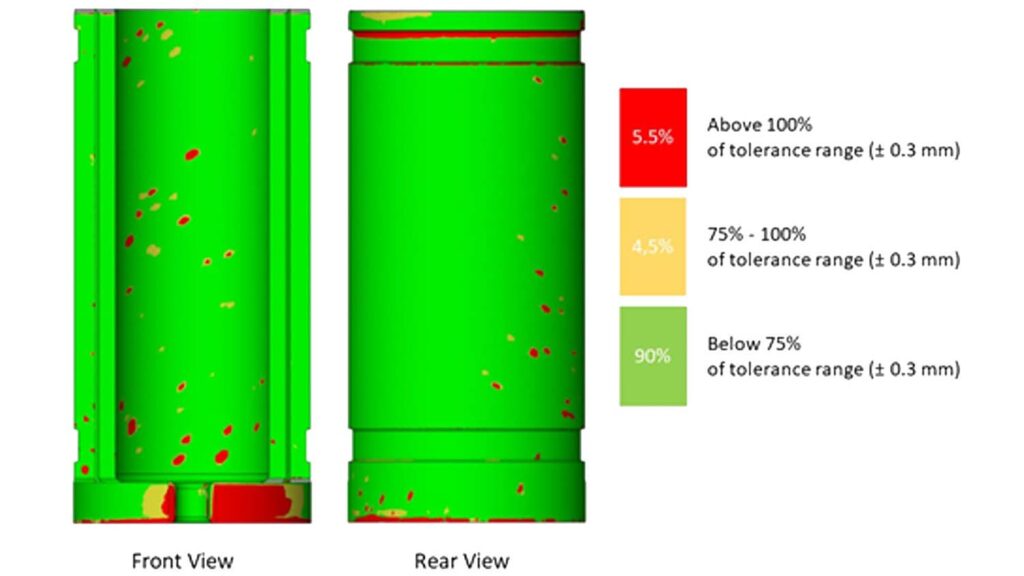

To assess the surface quality of the prints, engineers performed a high-resolution 3D scanning analysis on a select number of parts using a GOM Atos Core 3D scanner. The scan data showed relative deviations between the ideal CAD model and the printed part.

A ‘pass/no pass’ filter for dimensional accuracy with a threshold of 0.3mm enabled Hänssler to create an optimised ABS-ESD printing profile to print parts on the Ultimaker S5 with minimal tolerance limits.

The optimised material printing profile combined with the Ultimaker S5, resulted in parts with minimal batch-to-batch dimensional variation and untouched ESD performance, as well as temperature resistance for up to 90°C.

Adrian Heinrich, Hänssler Group marketing manager, said: “Besides the opportunity to create accurate and more complex parts with 3D printing, we also reported a reduction in material waste in the range of -80 per cent and -60 per cent in cost per part versus our traditional milling techniques.

“The accessibility and reliability of 3D printing and great support of Ultimaker’s ecosystem partner Kimya, made this project just the beginning,” he said.

“Ensuring high dimensional accuracy with 3D printing is key for companies that need to guarantee their customers every batch is identical and ESD safe. It should not matter when, where or who print the parts,” added Ultimaker CTO Miguel Calvo. “I’m proud of the close collaboration between Kimya and Ultimaker to make this happen for the Hänssler Group.”