Hexagon has announced two new wireless 3D scanners designed for measuring parts in a wide range of inspection environments.

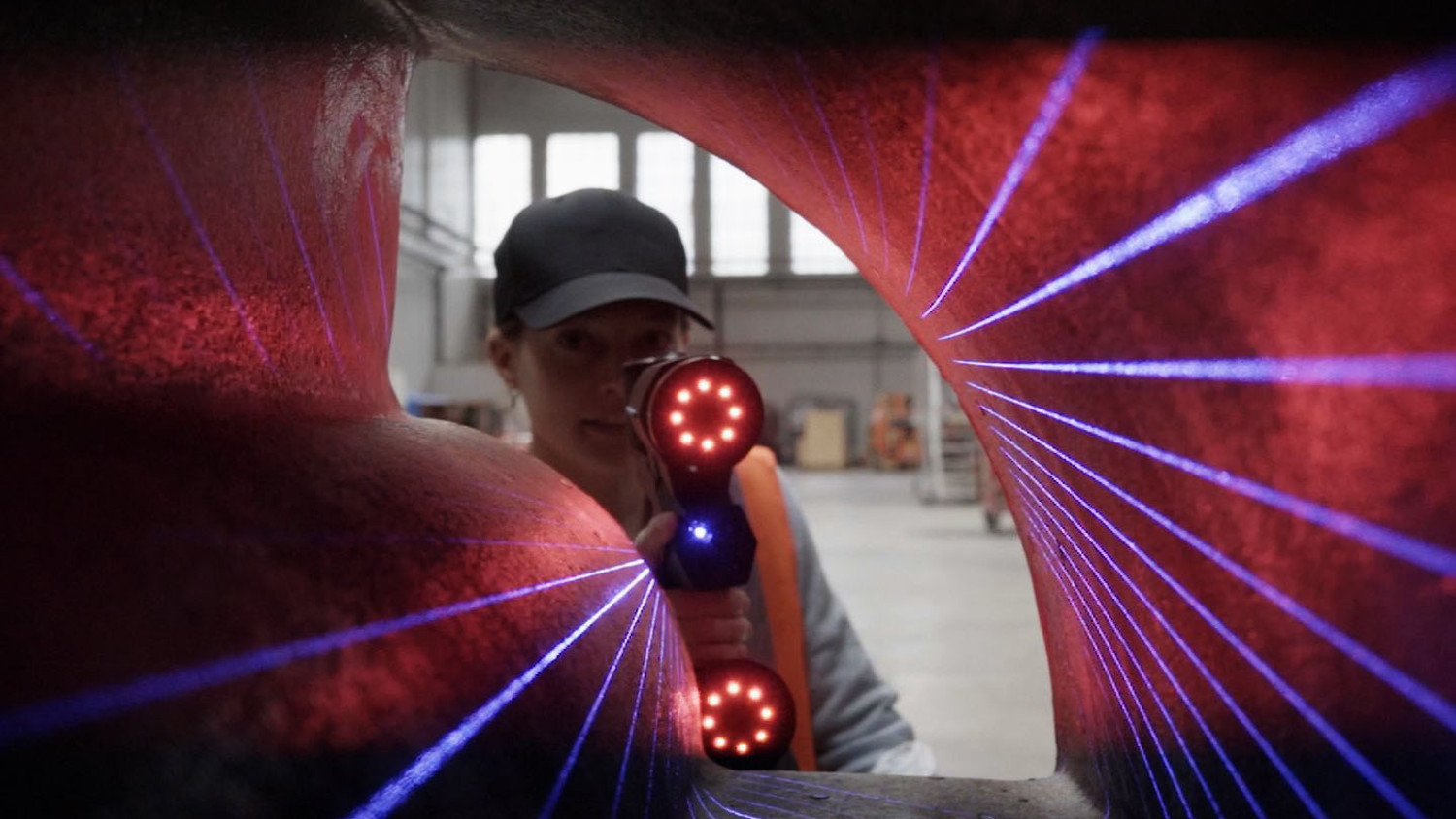

Hexagon’s Manufacturing Intelligence division has created the company’s first 3D scanners, Atlascan Max and Marvelscan that do not need a PC or any cables tooperate, and are battery-powered, making measuring surfaces in outdoor environments or confined spaces more practical.

Multi-mode scanning means users can switch between Fine mode, for scanning detailed surfaces with a high resolution, and Standard mode for scanning open surfaces.

All the data collected during scans is combined into a single point cloud regardless of which scanning mode was used to collect it.

Both scanners feature thumb-operated controls that are designed to be ergonomic.

It is not necessary to fix parts prior to scanning on either scanner, saving time and allowing greater measurement flexibility, or to measure holes and slots, as a hole-flash feature mode enables instant data capture.

Due to their large measurement standoff distance, Hexagon says that Atlascan Max and Marvelscan are ideal for integration within automated inspection processes mounted on industrial robots.

“Today, manufacturing and engineering teams recognise the value of up-to-date 3D scans throughout the product lifecycle. This means almost anyone might need to perform a metrology-grade scan of a part regardless of their location,” said Pirmin Bitzi, general manager for portable measuring devices at Hexagon.

“Our first handheld 3D scanners enable customers to digitalise parts without worrying about fixturing or environmental conditions and Marvelscan’s cutting-edge, integrated photogrammetry system aligns to reference targets without the need for stickering. Wireless and ergonomic, these scanners provide a seamless, instant scanning experience from the shop floor to the shipyard.”