Materials giant DSM has introduced glass-filled polypropylene granules optimised for 3D printing via fused granulate fabrication (FGF).

DSM claim the material will enable easy and consistent production of structural and demanding applications using the FGF process.

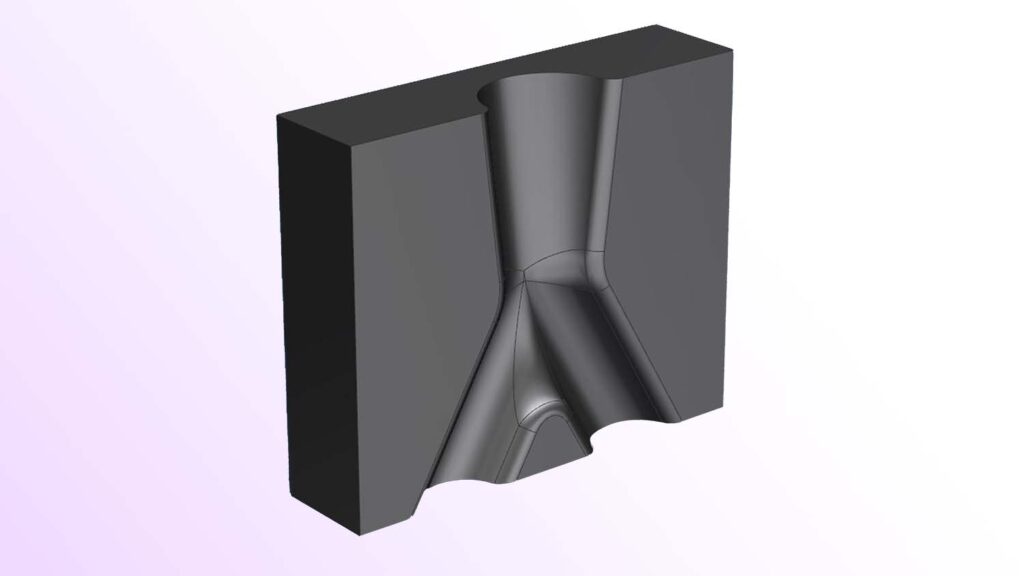

It hopes that this will appeal to automotive, industrial and infrastructure manufacturers – such as Sewage manholes, touted at launch as a possible application (main image) – looking to adopt additive manufacturing for low volume production, using the materials they are familiar with from traditional manufacturing.

DSM Arnilene AM6001 GF (G) – the (G) stands for granulates – stems from the same base material used in high volume production and is optimised for FGF 3D printing.

By combining materials knowhow, expertise in modeling and simulation, design for additive (vs traditional manufacturing) and printing expertise, DSM secured all of the desirable mechanical, thermal and chemical performance of glass filled PP with the flexibility of a proven 3D process.

DSM additive manufacturing innovations director Geoff Gardner, commented: “Availability of engineering-grade materials with the right property set is the next step in the additive manufacturing revolution.

“Developed by our experts, Arnilene AM6001 GF (G) offers industrial customers an industry standard material with robust mechanical, thermal and chemical performance in an additive manufacturing format.

“By using a material they already have experience with, they can fully focus on 3D printing and its benefits for their business.”

Currently FGF 3D printers are few and far between, although with pellet-form feed stock always touted as an easy means of driving down costs (utilising existing injection moulding materials), then this is an interesting move by DSM.