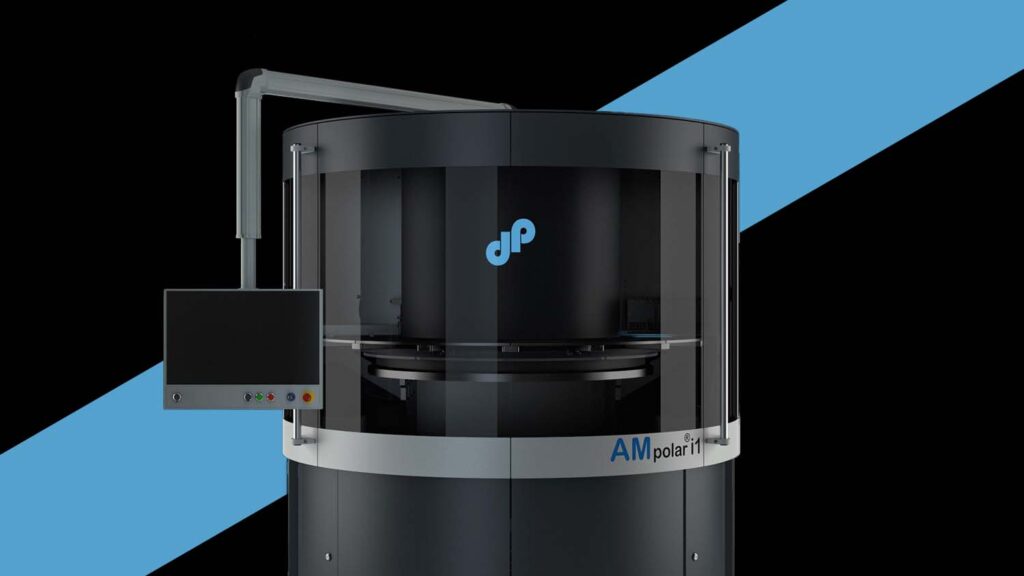

3D Systems has acquired DP Polar as it looks to accelerate its polymer 3D Printing technologies by taking advantage of DP Polar’s patented continuous printing process, which uses a stationary printhead above a rotating platform.

The large-scale, segmented, rotating print platform looks to eliminate the start/stop operations of virtually all additive manufacturing platforms and also has bonuses for longevity, with the process minimising the wear and vibration associated with traditional print head motion.

The rotating platform can be paired with a variety of printing technologies and can even accommodate pick-and-place robotic systems that can embed electronics or other features into the body of the component as it is printed.

The printing process designed by DP Polar also allows for simultaneous application of different materials to add desired performance properties in components – such as elasticity, hardness, temperature resistance, or colouring – with high precision.

With this acquisition, 3D Systems says it will leverage its polymer materials portfolio as well as Oqton’s software technology to bring true high-speed, mass production additive manufacturing to a breadth of industries.

“DP Polar has designed a very unique system that provides true high-volume production,” said 3D Systems CEO Dr. Jeffrey Graves. “The ability to print a broad range of materials, alongside the printer’s modular design that enables multiple processes in one high-speed platform not only increases productivity by orders of magnitude but also reduces the total cost of ownership.

Graves says that 3D Systems found the level of machine intelligence embedded in the platform’s operating system particularly impressive, enabling continuous operation across the large, rotating print platform. “This unique capability is central to the exceptional throughput, economics, and versatility of DP Polar’s 3D printing system,” he said.

“By combining our renowned polymer materials portfolio with this first-to-market high-speed production technology, I believe we’ll affect a monumental shift in production workflows for high-value applications in industrial and healthcare markets.”