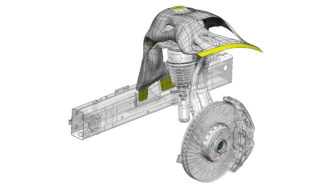

BMW has explained how from 2025 it will be using WAAM (wire arc additive manufacturing) to create lighter, stronger vehicle parts and generate less waste, to optimise its use of generative design tools.

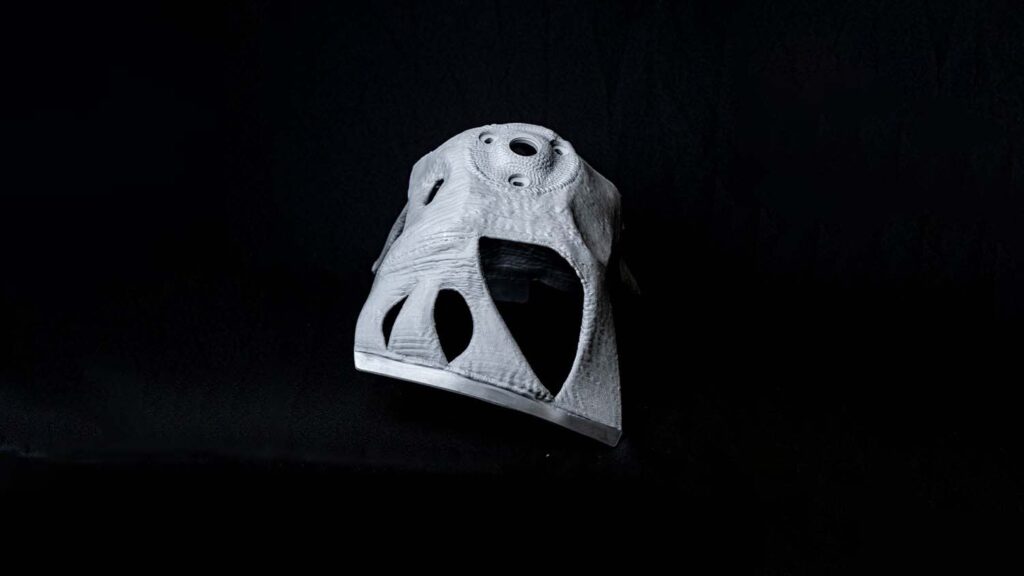

The WAAM process showcased uses aluminium wire feedstock being directly deposited via a laser welding head, allowing the automotive company to build lighter and more rigid than comparable large parts.

To optimise parts to be built with the technology, BMW says that a combination of the manufacturing process and a general new component design is paramount, for which BMW is accelerating its use of generative design, developing its own algorithms in close collaboration with interdisciplinary teams, in part ‘inspired by evolutionary processes in nature’.

“It’s impressive to see how WAAM technology has developed from research to become a flexible tool for not only test components but also series production components,” said Karol Virsik, head of BMW Group Vehicle Research. “The use of generative design methods enables us to make full use of design freedom and thus the potential of the technology. That was unthinkable just a few years ago.”

Despite the parts featuring a wide welding seam, BMW’s engineers demonstrated that WAAM components can still be used for high loads without needing a finished surface.

BMW has been trialling this DED process since 2021 at its Additive Manufacturing Campus in Oberschleißheim, Germany, where the first components will be made. BMW anticipates increasing production to other locations by using pre-existing assembly lines with new software.

The adoption of WAAM technologies will not replace SLS technology for more detailed parts, says BMW, but in terms of the possible size of the component and the deposition rate, wire arc additive manufacturing is ‘superior’.

The company is even considering the idea of using WAAM technology to produce individual components directly on the assembly line thanks to its ability to manufacture different parts without new tools, simply by changing the software.