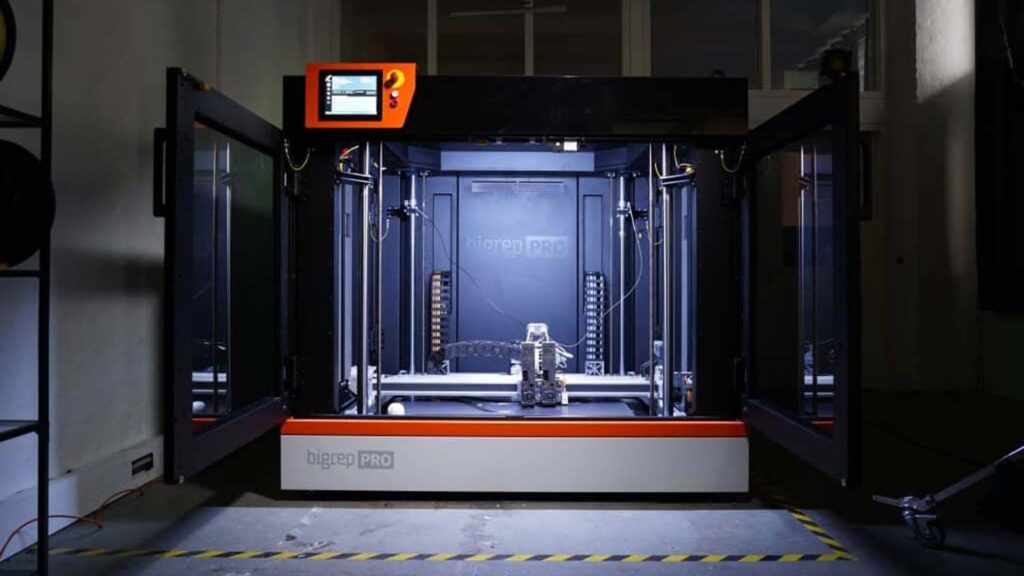

The latest BigRep Pro leads a new generation of products from the Berlin-based additive manufacturing experts, adding a new hybrid software-hardware solution, Jumpstart, that lets users start printing ‘within minutes’.

The BigRep Pro, a meter-cubed 3D printer designed with industrial needs in mind, combines three features within Jumpstart to make life easier for the user, first through a removable and flexible print bed surface that BigRep says eliminates the need for glues and removal tools. Second, a secure extruder mounting for greater precision throughout the entire print. Finally, BigRep’s MXT Controls System simplifies the user experience automating print bed and extruder calibration, ensuring that the crucial first printed layers are optimal every time.

The scale and versatility of the platform allows for full-scale, large parts including functional prototypes, factory tooling, patterns, moulds, and end-use parts.

The new BigRep Pro is now compatible with many fibre filled filaments including PA12-CF.

“We are excited and proud to present our new additive manufacturing solutions combining our diverse hardware, materials and processes, as well as software and controls expertise,” said BigRep MD Dr. Sven Thate.

“The new BigRep PRO was developed with our industrial users’ productivity and ease of use in mind.”

Additional upgrades to the BigRep range include the BigRep One, its original affordable large-format 3D printer, which comes with a new, lighter, and more precise portal and can be configured to the needs of the user. Users are able to choose from single, dual, or twin extruder modes plus

add-ons like an enclosed housing and even the printer’s colour to create the perfect machine just for them.