3DGBIRE has announced a partnership with CMG Technologies to offer debinding and sintering services for 3D printed parts made using BASF Ultrafuse 316L and 17-4PH filaments.

Previously parts had to be shipped to Germany, which has become an increasingly costly and prolonged process thanks to the effect Brexit has had on the movement of goods, prompting 3DGBIRE to set up the new service with CMG Technologies, which has over 20 years of experience within the Metal Injection Moulding (MIM) industry, which uses similar techniques and technology.

The service is billed as the first in the world that debinds and sinters 3D Printed and MIM parts in the same ovens at the same time. The combination of parts from different manufacturing methods leads to huge cost savings and reduction in lead time for customers using these services.

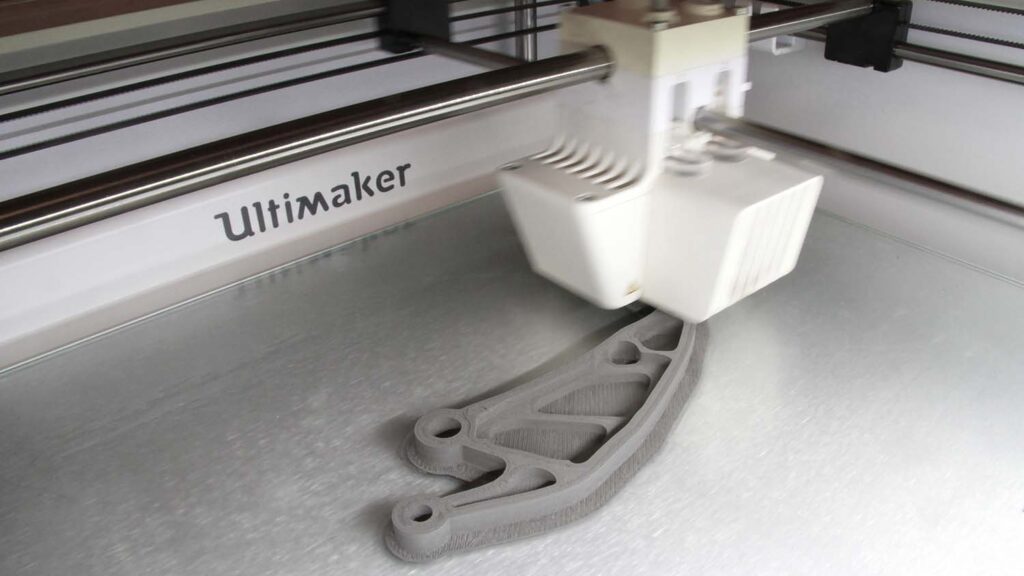

The primary aim of this partnership is to provide UK based debinding and sintering options for parts 3D Printed in BASF Forward AM metal Filaments, for which 3DGBIRE is the sole UK supplier, which can be used on a wide range of FDM 3D printers, including some desktop Ultimaker products.

Additional aims include offering finishing services for the parts, as well as encouraging the adoption of additive manufacturing by facilitating the training, up-skilling and professional development of staff within customer organisations.

“Before Brexit you could quickly and cost effectively ship parts and goods to Germany that is no longer the case, so we were very keen to establish a debinding and sintering offering in the UK that enables customers to realise the huge cost saving opportunities of Additive Manufacturing,” explained 3DGBIRE director Paul Croft.

“This is a very natural progression for us,” said CMG Technologies director Rachel Garret. “We can apply our skills within debinding and sintering of MIM parts directly to the debinding and sintering of 3D Metal Printed parts to ensure we are processing parts to the highest quality and accuracy.”