3D Systems has returned to the FDM spectrum of 3D printing with its two recent acquisitions – Titan Robotics and Kumovis – both of which have developed their own extrusion technologies.

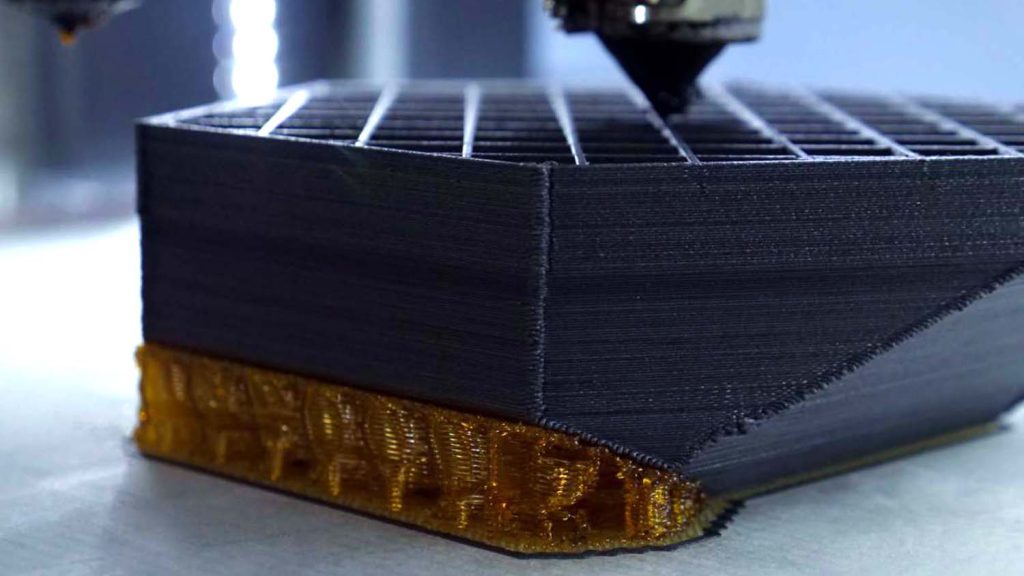

Colorado, USA-based designer and fabricator of large-format, industrial 3D printers, Titan Robotics produces application-specific processes, including hybrid machines that include pellet extrusion, filament extrusion, and a spindle tool head configurations for precision finishing.

With this acquisition, 3D Systems says Titan Robotics will expand the strength and breadth of its polymer 3D printing solutions portfolio to address ‘new applications’ in markets requiring large build volumes

“Through the innovative modular approach of their printers, and the ability to use both pellet and filament product forms in an open architecture with widely available production polymer systems, we believe the adoption rate of industrial 3D printing will continue to accelerate,” said 3D Systems CEO Dr. Jeffrey Graves.

Example Titan Robotics solutions include large format 3D printers with heated build platforms and chambers that scale from 762 x 762 x 1143mm to as large as 1270 x 1270 x 1829mm that boast print speeds up to 30,000mm per minute.

As a customer’s application focus expands in the future, the modular Titan system can be upgraded to accommodate new materials and product configurations to best meet their targeted performance and cost goals.

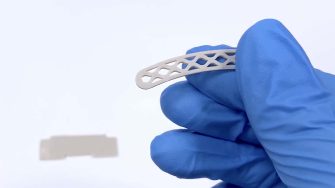

The second acquisition is Kumovis, a Munich, Germany-based additive manufacturing solutions provider for personalised healthcare applications.

Kumovis’ solution is built upon its filament FDM extrusion technology that it says has been specifically developed for precision 3D printing of medical-grade, high-performance polymers such as PEEK for human implants and surgical instrumentation applications.

3D Systems says the move will add a unique extrusion technology to its polymer printing healthcare portfolio, along with its unique ‘integrated clean room’ printing technology, that can help hospitals and end-users to tailor products on-demand to meet specific patient requirements in the quickest and most resource-efficient manner.

Both moves will position 3D Systems with a greatly expanded polymer additive manufacturing range – its first real moves in the FDM sector since shutting down its desktop Cube range in 2015.

The adoption of direct pellet-fed 3D printing opens up not only a wide choice of material options, with hundreds of formulations commercially available ranging from low durometer (soft) to high performance and highly filled resins, such as high loadings of carbon fiber and glass fiber, but a faster route to qualify parts.

However, despite being much vaunted – including by 3D Systems’ great rival Stratasys in its Infinite Build concept machine a few years ago – this has been a route less adopted.

Injection moulding experts Arburg launched its efforts around 2015, however the machines were never adopted for mass manufacturing, and were really more to qualify injection moulded parts, rather than replace them.

However, materials manufacturers would greatly welcome the use of its already plentiful pellet stocks, with pellets optimised for additive manufacturing being launched by the likes of DSM in recent years, while the addition of water-soluble support material and in-chamber CNC machining adds a whole new dimension.

The move into high-performance polymer materials is a much more crowded market. However, with 3D Systems now being on a much more defined and organised path in terms of its acquisitions and strategy (no more Cubes), its medical arm will likely continue to target Kumovis‘ existing market, while no doubt making use of its air filtration and monitoring technologies.