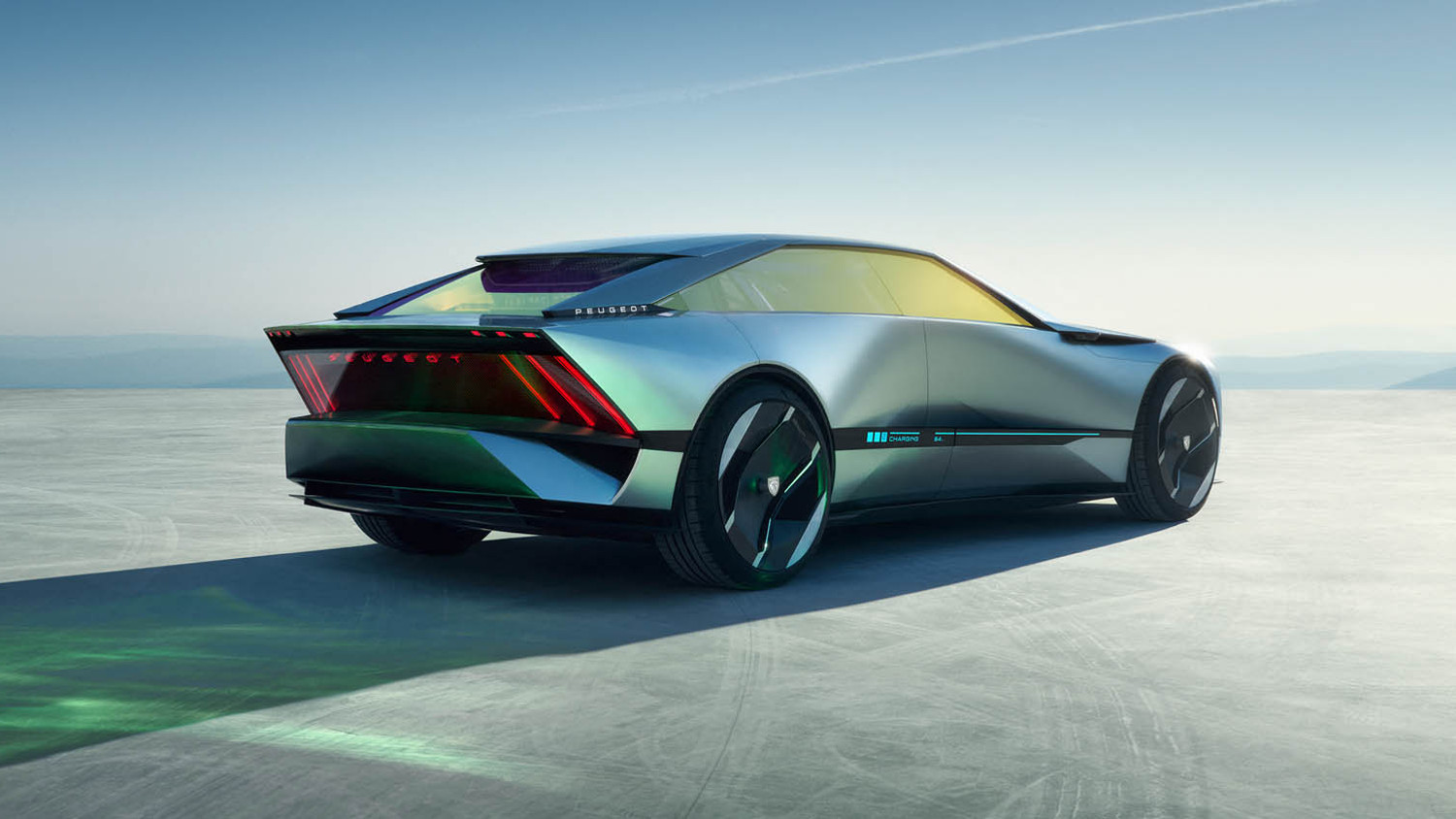

Heralding a new era for electric vehicles at Peugeot the brand’s Inception concept car boasts 3D-printed textural patterns applied to its interior fabrics and seats, in order to enhance the form and function of this futuristic vision

A concept car exists not just to present a vision of exterior design intent, but also to showcase creative ideas for interiors. That is certainly the case with Peugeot’s Inception concept model, launched at the Consumer Electronics Show in Las Vegas in January.

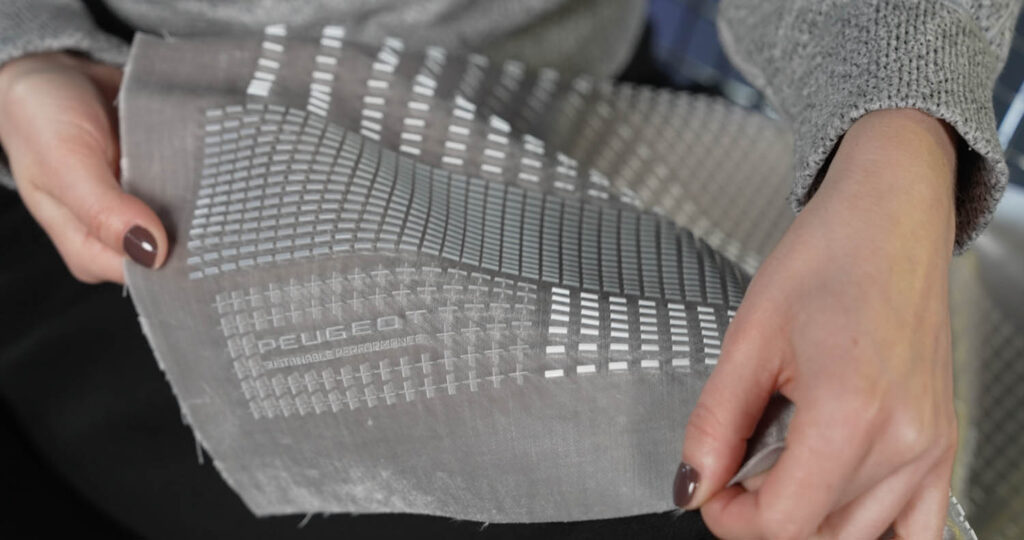

The interior of the car uses a velvet material that extends from the seats to the floor and features stunning 3D patterns created using Stratasys’ 3DFashion technology.

With Stellantis-owned Peugeot’s design for electric vehicles (EVs), a minimalist, angular interior supports the overall objective of reinventing the driver experience. Integral to this experience are these fantastic velvetcovered seats made from 100% recycled polyester.

“At Peugeot, we always like to combine function with aesthetics,” says Maud Rondot, Peugeot’s head of CMF design, the department responsible for the future vision of the Peugeot brand.

“Our objective with the Inception concept’s seating area was to modernise the velvet material used and decompartmentalise the design by extending it to also serve as a visually impactful floor mat,” she explained.

A fundamental theme of the Inception concept was to capture the relationship between materials and light, which required the Peugeot Advanced Design team to use materials that were in keeping with the car’s specific look and would embody the brand’s vision for future EVs.

Peugeot worked with single material effects, selecting a metallic shade for the velvet, which is designed to look futuristic while playing with light, before adding the semi-transparent ‘micro-architectures’ across the seats and floor.

“Instead of covering the whole stretch of material, it was really advantageous that we could leave the velvet visible,” says Rondot. “3D printing gave us the ability to modify and reprint the files very easily, but also important is its durability and efficiency. Indeed, as a technology, it doesn’t require moulds, which is revolutionary in terms of industrialisation.”

Produced using the TechStyle edition of Stratasys’ J850 3D printer, the process is capable of full-colour, multi-material 3D designs that can print seven different materials directly onto fabric at the same time, along with transparencies and detailed textures.

Rondot explains that with current embellishment methods, it is not possible to build thickness and height to the extent that Stratasys’ 3DFashion technology allows. Where the floor area space would typically need to be treated with a protective overlay, the Inception concept instead leverages direct-to-textile 3D printing.

Says Rondot: “Often, there is a delta between what we imagine and what we can obtain, so it was quite magical to see our idea arrive precisely as envisaged and with a remarkable quality of execution.”