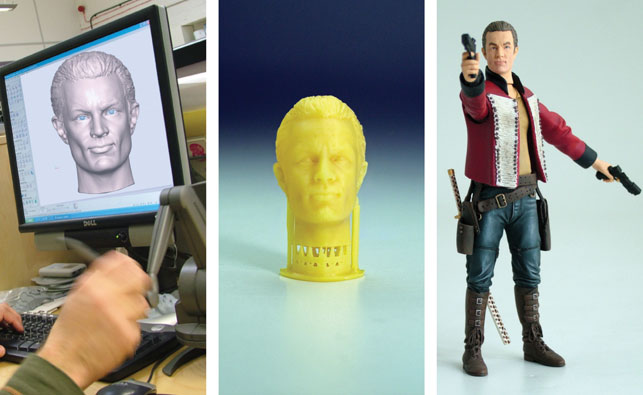

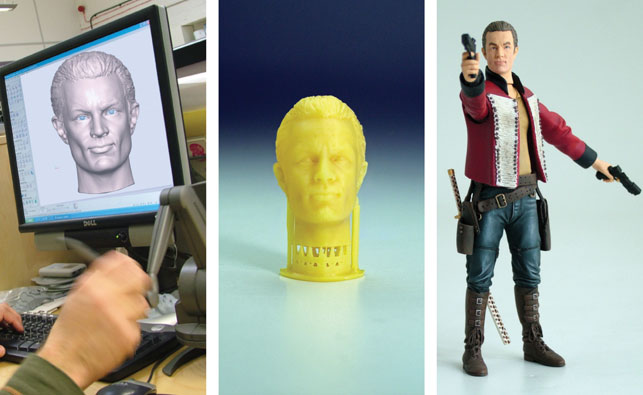

(L to R) Torchwood’s Captain John Hart sculpted using SensAble’s FreeForm; a raw Perfactory print of Captain John, and a final decorated prototype

A visit to Industrial Plastic Fabrications (IPF) is, quite literally, an experience in all that is bright and modern in the world of rapid prototyping. It’s with a defeated smile that head of prototyping, Gary Miller, explains (for possibly the thousandth time) why he is dressed in a polo-shirt ‘hot pink’ in colour.

The entire company underwent a makeover of ‘Gok Wan’ proportions last year, wheeling in a marketing team to transform an already successful business into a conjoined enterprise with a modern, striking identity. Split into sections, the RP department was branded with an eye-burning magenta that 1980s Barbie would be proud of. Yet it’s less ‘doll house’ and more ‘Action Man’ when it comes down to the typical projects it takes on. Equipped with the first Objet Connex 500 in the country, an Objet Eden 350v, and a high detail EnvisionTec Perfactory, the business is well positioned for a variety of clients including high detail figurine production.

Science fiction

How to make a Cyberman

Stepping into the RP bureau space in the top level of IPF’s headquarters in Nazeing, Essex, you find a gallery of spacemen, aliens and famous faces in miniature form. Easily the company’s most eye-catching work, the litany of action figures licensed from major sci-fi series’ such as Doctor Who and Torchwood stack the shelves in various limbs and parts. A line of ‘severed’ heads display just how detailed the Perfactory machine can be as David Tennant, John Barrowman, and a determined looking Cyberman stare into the middle distance.

Action figures form a key part of IPF’s RP division, with the team also contributing to other small but detailed models, whether it be a miniature Lewis Hamilton or a range of fishing lures.

The mini multi-lense Perfactory machine is ideal for the detail of the small parts. As Gary explains, “What it enables us to do is change the resolution of the part we can produce on it. A lot of people use it in the jewellery trade, but we tend to use it in the figurine market.”

The bright new marketing and a fun line of projects aren’t the only modern aspects to the company. The technology that Gary works with needs to be bang up to date to keep up with the constant demands on throughput. 18 months ago IPF purchased a Connex 500 machine and while at the time it was considered a bit of a gamble, it is now looking as though it has paid off.

“We’ve increased resin consumption by 40 per cent on the previous year and it’s going from strength to strength,” says Gary. “I think that’s down to us being so unique.” Turnover speed is a resounding factor for the business, with Gary putting in many unsociable hours to make sure a job can be pushed through to meet the client’s demands, while having the trust in the machinery to maintain the high levels of detail and quality.

The large build volume of the Objet Connex500 and its ability to print in more than two materials simultaneously is invaluable for IPF

“It’s the service I guess, but also the fact that we’ve got quite a large capacity – the Connex has a large build envelope and we have that backed up with the Eden 350V,” says Gary of the two large Objet machines that stand chest-high in the workshop.

Since taking on Objet’s Connex 500, IPF has maintained strong links with the Israeli company in order to get the best from its machines and to maximise the benefit to its customers by knowing what will work best.

Medical attention

The versatility of the machine means that IPF is not limited to science fiction, but also science fact by taking on a number of medical projects, while being able to use the different ranges of resin to make extremely life-like prototypes of consumer products.

“All the time we’re prototyping things that are as close to the final product as can be with prototyping. Rigid, flexible, a combination of them both, over-moulding; so the client can see, before pressing on with expensive tooling, what the product is going to look and feel like.”

It’s an attractive proposition for designers to be able to get their hands on a physical model to test from an early stage in such a quick turnaround time, which in terms of ideas is almost as bright as Gary’s pink polo shirt.

Toy story

Figurative sculpting is a speciality of IPF having worked on a wide range of collectable figures and children’s toys.

A large proportion of these have been designed by Windsor-based Designworks, which has a thirty strong design team specialising in freeform and digital sculpting.

Having a bureau service like IPF available gives Designworks a greater level of flexibility. “IPF fit into a lot of the different areas. We can use their RP process for master models for prototypes, equally as part of the development of a product,” explains Ed Barnett-Ward, Designworks director of sculpting. “The Objet and Perfactory printers are pretty much the best on the market.

“They suffer from a very high price tag and maintenance. It’s better for us not to buy them and to use a bureau as it takes out the stress and the strain of that part of the process.”

The highly detailed output from the Perfactory machine means the most can be made of scanned data, which is used to create the 15mm heads of a five inch action figure. Getting sculpts approved can be hard as the actors being produced in plastic have rights to their likeness. “But now scanning takes that out of the equation – if you’ve digitally scanned something it’s a true reflection,” says Ed. “It makes everything a lot more reactive in terms of what we do. When I started nearly 20 years ago, everything with a license was worked on a year in advance, but now we can work on things quicker and be more reactive.”

At the time of going to press Designworks was preparing to have new models ready for the London Toy Fair, some of which IPF was producing on a ‘same-day’ basis to meet the rush. “It’s living and breathing proof that we can do a same-day turnaround: printed at night and some of the parts printed the next morning, and them all sent over that afternoon as it was that urgent,” says Gary as the latest fleet of figurines were prepared for action.

Such is the speed of the entire process, Designworks can start with nothing, and have a full range of new action figures on shelves in three months. With the latest Doctor Who television series approaching fast, they won’t need a Tardis to have things ready on time.

www.designworksgroup.net

Industrial Plastic Fabrications prototypes lend a scary face to Doctor Who villains