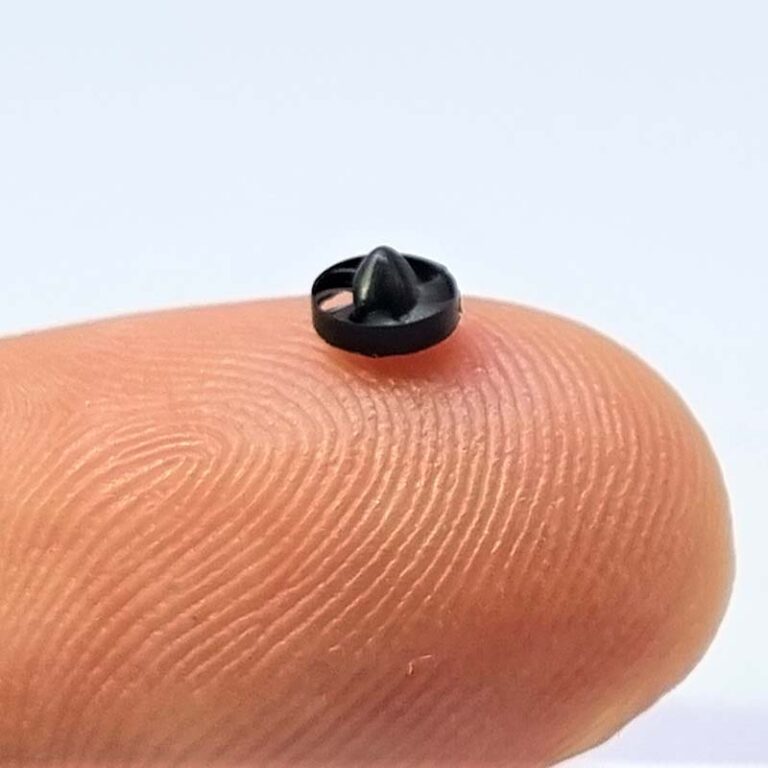

Fabrica Group is working at the cutting edge of additive manufacturing (AM), which as a technology has until recently been unable to attain the tolerances and accuracy demanded by companies looking to miniaturise plastics parts and components.

Fabrica Group has now commercialised its Fabrica 2.0 technology which for the first time can attain micron level resolution repeatably, and therefore for the first time provides an alternative production process to micro moulding.

We sat down with Avi Cohen, EVP Sales at Fabrica Group, whom is quite known in the 3D Printing industry for more than two-decades – to get some answers and details about Micro AM and its unique benefits.

Where can companies see your technology and more importantly see the parts that you can make?

It needs to be realised that we commercialised our technology during the pandemic lockdown, so we have only just begun to meet customers and masses face-to-face. We recently returned from a successful Rapid TCT event, and we are proud to be able to attend the Formnext 2021 event in Frankfurt, Germany 16-19 November 2021, where attendees are invited to come and see the Fabrica 2.0 up close, and also look at some of the parts made using the technology which can achieve sub-micron tolerances. Fabrica Group will be on the Nano Dimension stand, Hall 12.1 booth C131.

Fabrica Group is aware — as the first movers in the Micro AM space for production — that it needs to establish partnership relationships with its customers that extends from product inception through to mass manufacturing. As such, Formnext represents a perfect place for customers to engage and discuss the specifics of their particular applications. In 2022 we will be attending a series of events across the world, and look forward to engaging with as many customers as possible in the short to medium term.

Can you briefly explain how the Fabrica 2.0 works?

The Fabrica 2.0 is based around a Digital Light Processor (DLP) engine, but to achieve repeatable micron levels of resolution combines DLP with the use of adaptive optics. This tool in conjunction with an array of sensors, allows for a closed feedback loop, the reason that Fabrica 2.0 system can achieve very high accuracy while remaining cost-effective as a manufacturing solution. In addition, through rigorous R&D, Fabrica Group has managed to develop its own proprietary materials (based on the most commonly used industry polymers) which enable ultra-high resolution in parts built.

So what does that mean for the nature of the parts that the technology can produce?

It is only through the unique combination of hardware, software, and material innovations at Fabrica Group that we can claim that the Fabrica 2.0 is the first AM machine to not just be able to achieve unmatched precision and accuracy, but to be able to do so while at the same time being commercially viable in terms of speed of production and cost of production. The Fabrica 2.0 is now proven to be a game changer when it comes to opening up the advantages of 3D printing to the micro manufacturing world for the very first time. Design engineers and OEMs can now see that restrictions that they have to work within when designing and manufacturing for traditional manufacturing processes are no longer there. As such the Fabrica 2.0 and the use of 3D printing for micro manufacturing will be the spur to innovation and increasingly cost effective, speedily produced mass customizable micro parts and components into the future.

What does the commercial availability of a Micro AM technology mean for industry?

Well, the ramifications are profound. Traditional micro molding is ideally suited to extremely high volume runs, due in no small part to the requirement for extremely costly and time-consuming micro tools. The expense associated with micro tooling means that only when parts are mass produced in the millions will it be cost-effective. OEMs requiring prototype, small, or medium volume runs are left with limited options but can now use the Fabrica 2.0 Micro AM technology to manufacture smaller numbers of parts cost-effectively.

AM requires no tooling, and therefore provides an agile and attractive alternative to legacy production processes when it comes to lower volume runs. In addition, AM is agnostic to geometric complexity, which means that it stimulates innovation as it opens up the production of parts and components impossible via traditional manufacturing technologies.

Existing at the interface of AM for production and the industry-wide drive towards miniaturization, Fabrica Group’s industrial next-generation micro 3D printing technology lifts the lid for designers and manufacturers in their quest to embrace the inherent advantage of the technology, and enables them to exploit the ability that exists through 3D printing to build complex parts in small, medium, and high volumes in a timely and cost-effective fashion.

It seems that Micro AM, bring a certain interest and breeze to the traditional AM industry. Can you tell us more?

For many manufacturers, the goal when looking at AM as a production technology is high volumes. The ability to mass produce AM parts without the need for time consuming and costly hard tooling, and with all the advantages AM brings in terms of agility and geometric complexity impossible using traditional production techniques is a goal the Fabrica 2.0 makes attainable on the micro scale.

Boasting single micron resolution, Fabrica Group’s technology is targeted squarely at the optics, semi-conductor, micro-electronics, MEMS, microfluidics, and life sciences sectors. These sectors exhibit high-level demand for accuracy and complexity, and until now the only route to market has been through disproportionately expensive or restrictive traditional manufacturing technologies.

You can contact Avi Cohen at Fabrica Group today via Avi.C@nano-di.com to arrange a face-to-face meeting with the Fabrica Group team, who will be happy to discuss the specifics of your particular applications.