We are in a transformative time for product development, characterized by advancements in sustainability, artificial intelligence, electrification, and connectivity.

Companies that effectively leverage these innovation opportunities will emerge as leaders. The journey of true product innovation begins with outstanding design in the concept phase.

Benefits of MODSIM

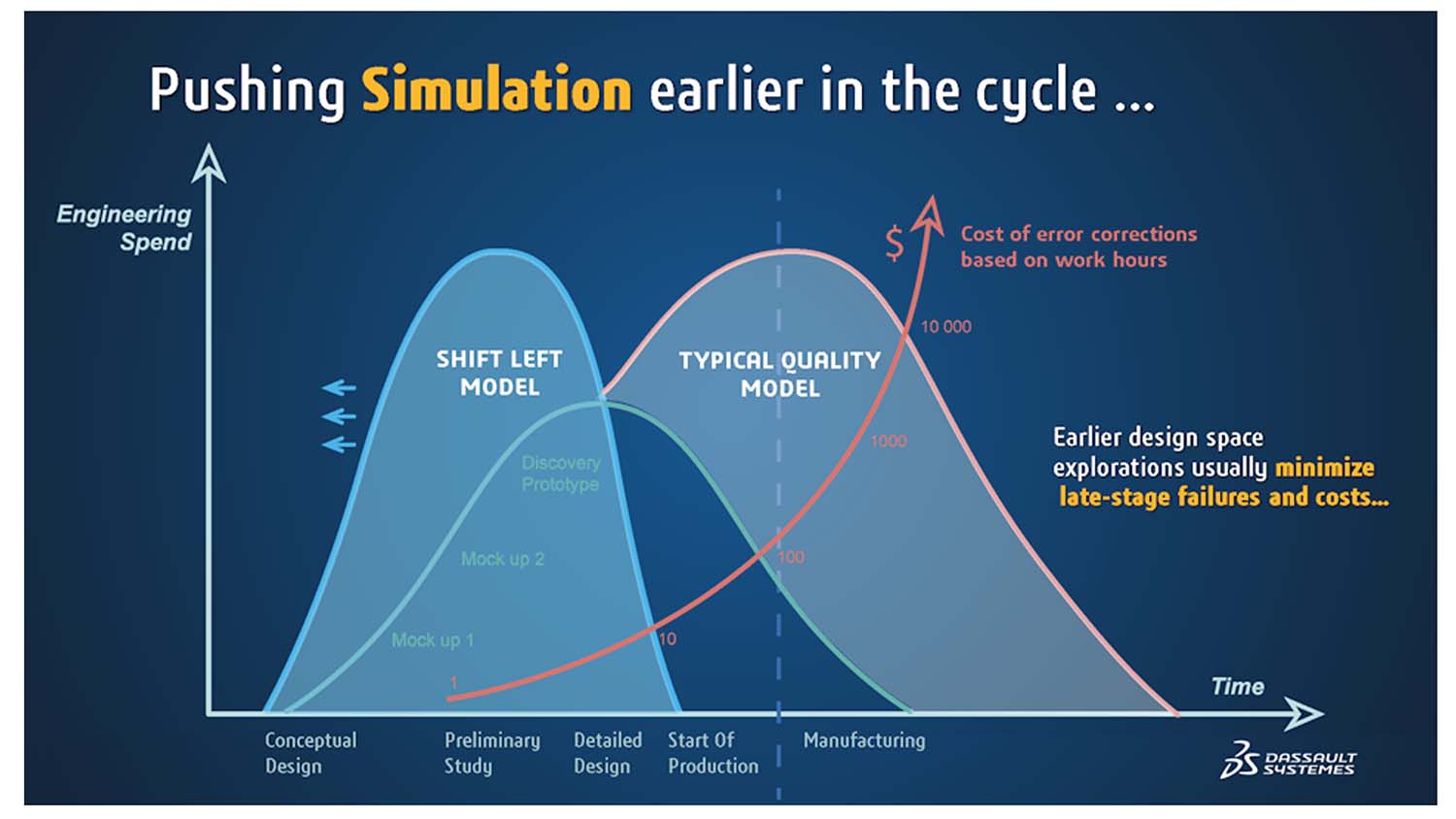

Integrating CATIA Modeling with SIMULIA Simulation gives designers early access to simulation capabilities. When designers, mechanical engineers, and simulation engineers work with the same data model, they can validate design concepts early in the process.

This efficient collaboration allows for quick design iterations—designers are able to modify simulation data and re-run simulations, leading to more informed decisions.

By adopting this performance-driven approach, teams accelerate innovation cycles. As a result, they can achieve faster iterations, resulting in market-leading products.

“With robust CAE processes at the concept design phase, designers are realizing that what we are doing through optimization is lowering their costs, their weight and improving their performance, and it’s not a trade-off. Value is going to go up because you spend less money on testing, and time to market has been shrunk because of this collaboration.”

Behrooz Shahidi

Manager,Ford Motor Company CAE Integration Department for North America and Europe vehicle programs

Addressing Development Challenges

As competition intensifies, engineers must navigate the complexities of balancing performance, quality, and cost. A fragmented approach often leads to late-stage design issues that result in higher costs and complexity, posing significant challenges for development teams.

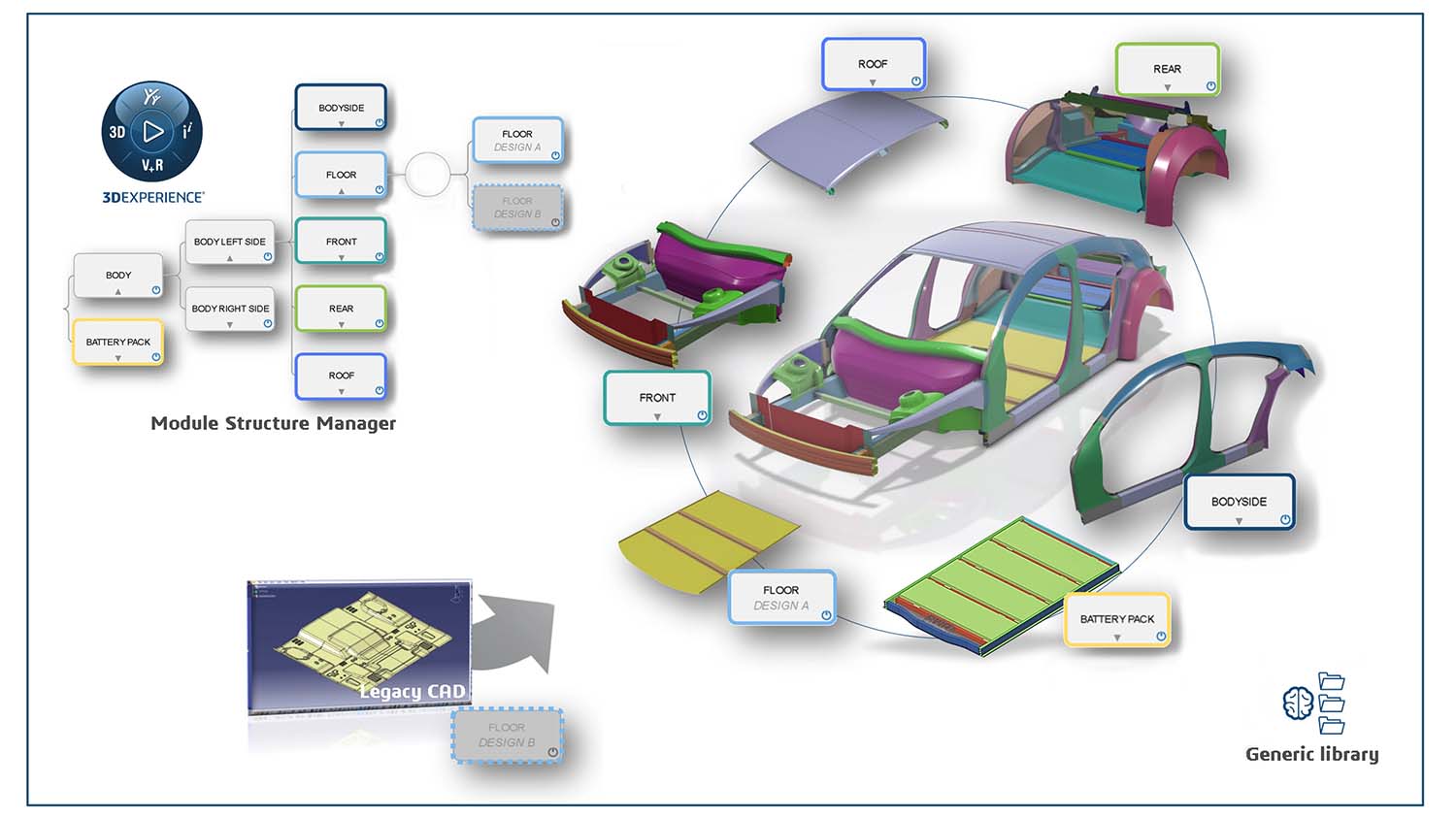

The 3DEXPERIENCE platform fosters seamless collaboration among all team members.

“CATIA helped us to make simultaneous engineering real.” How? “Starting after the ideation phase, we generated the conceptual design […] to validate the model and the composite layout structurally. 3DEXPERIENCE helped us build up the model accordingly and ensure that bikeframe resists the static load cases as well as achieves an outstanding lightweight performance, which is what we aim for in the end. Amongst others, in this bike project, we can take advantage of the close interface between CAD modeling and FEA simulation within the 3DEXPERIENCE-platform.”

Denis Schmitz

EcoDesigner for Mobility, DeSde Creangineering.com

CATIA Engineering, powered by AI, takes advantage of existing legacy assets to automate repetitive tasks in accordance with your company’s design & engineering rules. This frees up valuable time for more innovative alternatives, by automatically generating accurate ones.

Designers and engineers can then focus on more complex engineering topics, with the help of unified, dedicated virtual assistants. Your competitive advantage will be strengthened by the limitless possibilities of AI-powered engineering solutions.

“Generative design is like asking nature how it would solve a problem. It feels like collaborating with the Earth itself in creating something efficient, elegant and logical.”

Patrick Jouin

Designer

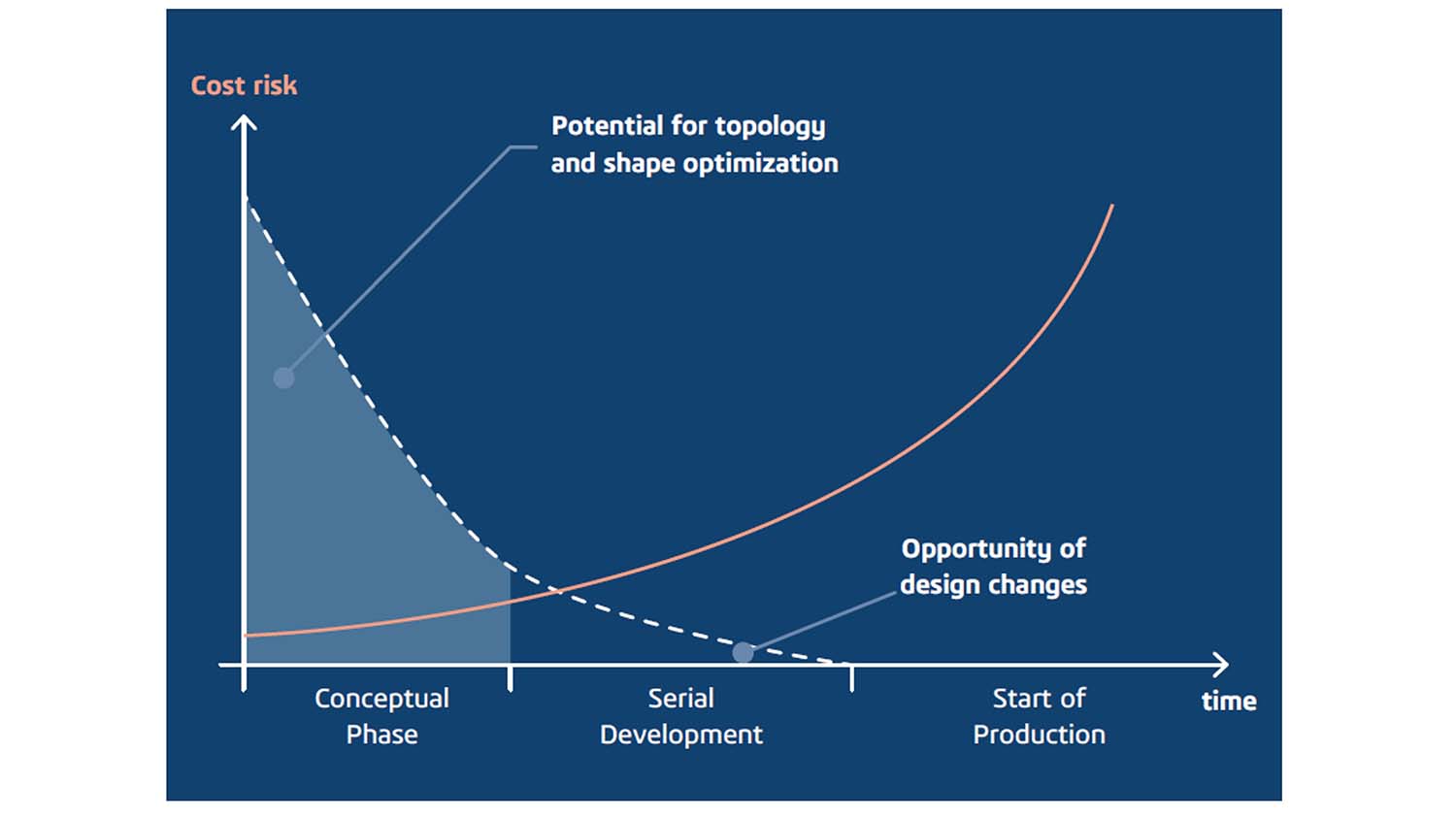

Early Optimization

Establishing a consolidated view of design information as early as the concept phase is crucial. This early optimization not only facilitates exploring your designs for good performance and high robustness, but also optimizes the corresponding tools.

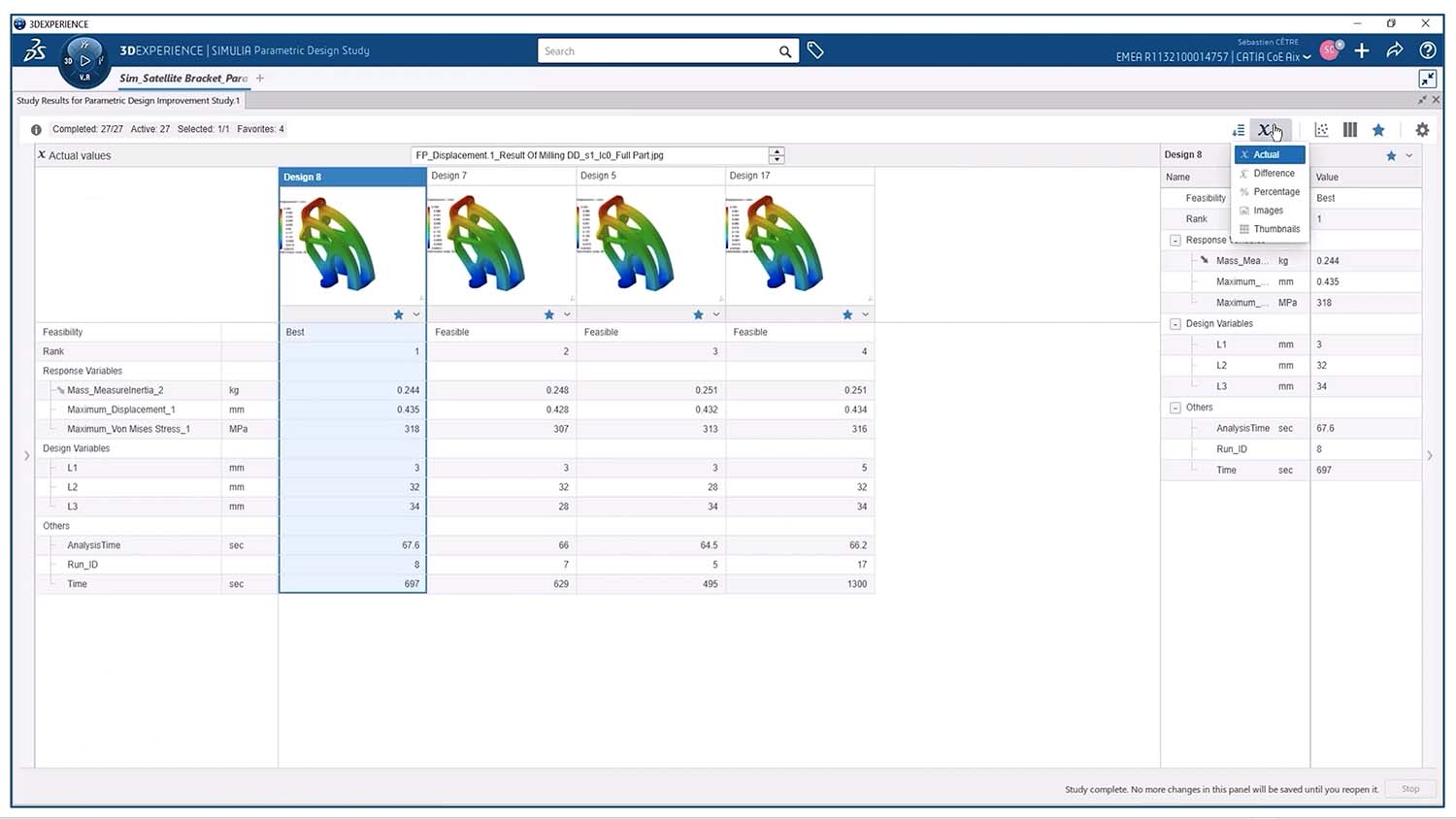

With easy access to geometric and simulation parameters, as well as formulas and configurations, designers can run automated parametric design studies. They define constraints and targets for your KPIs and quickly explore the design space. They can also investigate how tolerances will impact your product behavior and KPIs.

“We design with CATIA, generate the surfaces, mesh the model, run the simulation and then bring those results directly back into the design environment,” Jansonnie said. “Within the context of the full structure, we can see which parts are working properly according to the flow. It’s much smoother to exchange ideas.”

Olivier Jansonnie

Technical Director, Peugeot Sport

In addition, engineers can compare & correct load-induced deviations using virtual-to-real shape morphing. This process minimizes costly issues that may arise later in the product development cycle.

Democratization of Simulation

Equipping teams with simulation tools enables them to make more informed design choices. These scalable performance simulation solutions address all physics and provide valuable optimization to designers.

By fostering collaboration between engineers and analysts, organizations can enhance competitiveness and drive the development of superior products while reducing late-stage complications.

- Read more about StrongByForm and its sustainable materials innovation

- Watch the Interactive eBook for market-leading products

- Discover how a chair is redefining how we approach design and innovation

- Explore also how MODSIM is used in architecture with the Beijing Institute of Architectural Design

- Building the new PEUGEOT 9X8 Hybrid Hypercar from scratch