Whether it’s designing new products or solving the most challenging engineering problems, product development professionals in the manufacturing industry are turning to solutions that help them stay competitive and keep up with project demands.

The design and manufacturing of physical products can be incredibly complex. Engineers and designers must find ways to accelerate concept development, perform realistic simulations, and improve productivity across global teams.

Groundbreaking hardware and software tools, powered by NVIDIA RTX technologies, are unlocking new capabilities in design and engineering workflows. Professionals can create and deliver realistic visualization and simulations, whether it’s for automotive models or consumer products — and they can do this with real-time rendering, large GPU memory, virtualization, extended reality (XR) and a platform for full fidelity visualization and simulation of digital twins.

Accelerating Design and Simulation With Real-Time Rendering

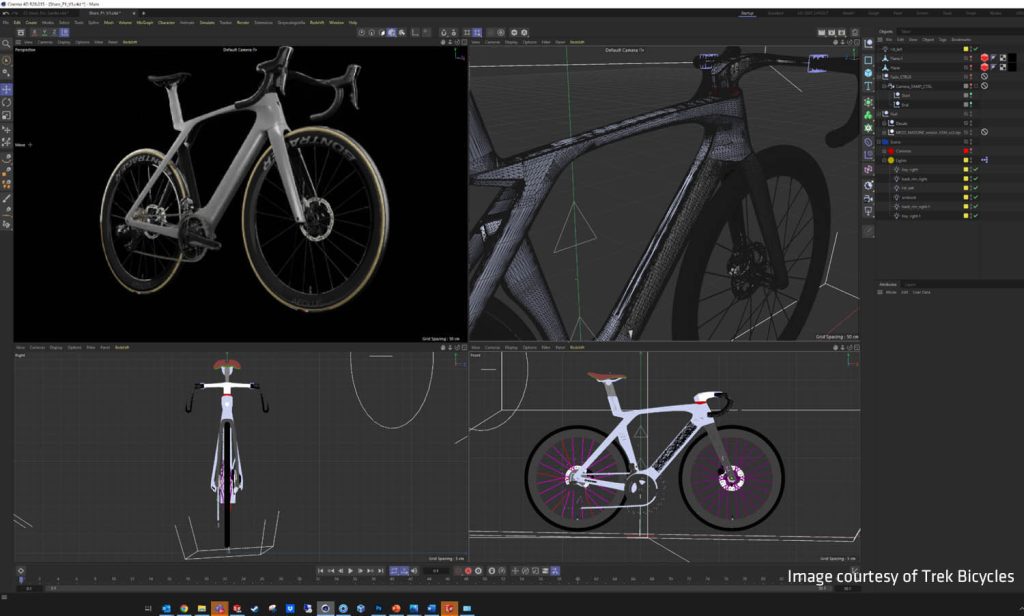

GPU-acceleration in 3D design and engineering applications is helping manufacturers handle large, complex models, render photorealistic images, and run engineering simulations — all in real time. Designers and engineers can tackle computing and multitasking with NVIDIA RTX, which allows them to leverage real-time ray tracing to accelerate production workflows while boosting productivity and efficiency.

One example of this is Alstom, a global leader in the mobility industry based in France. Alstom provides a range of equipment and services, from high-speed trains and metros to customized services and more. With NVIDIA RTX, Alstom designers can speed time-to-market and use GPU power for their design workflows.

Concept review and customization with Autodesk VRED are significant components of Alstom’s design process. And the team reviews these designs on a 16- million- pixel stereoscopic power wall display using NVIDIA RTX GPUs to achieve high quality real-time ray tracing.

Large GPU Memory

Real-time ray tracing can help engineers and manufacturers enhance their designs, but there’s another component that can make a huge impact on design workflows — GPU memory.

The GPU memory, often referred to as VRAM, is an ultra-high-performance pool of memory dedicated for use by the GPU. This memory offers significantly higher performance than the RAM used by the CPU. The product development process generates massive amounts of graphics data coming from 3D models, rendering scenes and engineering simulations.

NVIDIA RTX professional GPUs deliver large GPU memory and bandwidth, so users can easily handle massive datasets and complex 3D models. The large GPU memory also enables professionals to tackle multi-app workflows and graphic-intensive applications.

In addition to real-time ray tracing and rendering, the Alstom team utilizes the 48 GB GPU memory of the NVIDIA RTX™ A6000, the largest VRAM in workstation cards. And with NVIDIA NVLink doubling it, Alstom experienced an increased performance of 40x more than previous GPU generations.

Digital Twins Deliver Greater Efficiencies and More Possibilities

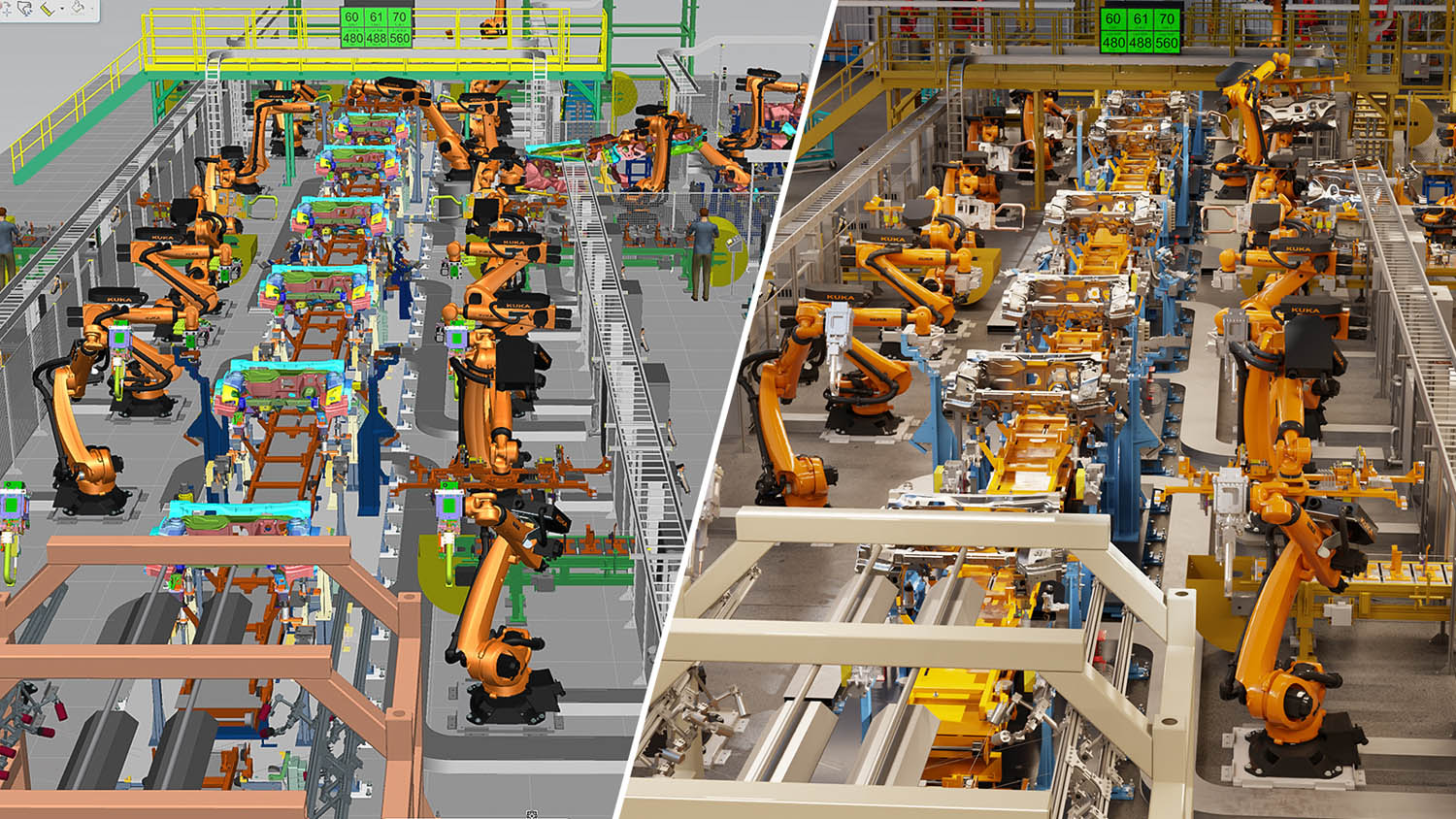

As per an ABI Research report, spending on industrial digital twins will grow from $4.6 billion in 2022 to $33.9 billion in 2030, at a 28% Compound Annual Growth Rate (CAGR). Manufacturing companies are using digital twin simulations to reach new levels of innovation and productivity. To create these realistic digital twins, businesses will need multiple platforms and advanced technologies — and NVIDIA Omniverse Enterprise is the solution that will connect them all.

Omniverse Enterprise is a real-time virtual world simulation and 3D design collaboration platform that streamlines complex workflows. It enables global teams to work together simultaneously across multiple software suites in a shared virtual space. Using Omniverse Enterprise, companies can build scalable digital twins, and manage massive, complex data sets from various 3D content creation applications.

BMW Group is one the leading companies using digital twins to create greater operational efficiencies with NVIDIA Omniverse Enterprise. One of the largest auto manufacturers with 31 factories around the world, BMW Group is creating industrial digital twins of several of its automotive factories.

The powerful capabilities of digital twins are still expanding. Recently, NVIDIA and Siemens announced they will connect the Siemens Xcelerator and NVIDIA Omniverse platforms, bringing digital twins within easy reach.

Powerful Virtual Performance For Any Workflow

Virtualization helps professionals run advanced graphics and computing workflows from the data center or cloud. Advanced solutions like NVIDIA RTX Virtual Workstations (vWS) deliver powerful virtual workstations from the data center or cloud to any device. Millions of engineers and designers can access the most demanding applications from anywhere with these high-performance virtual workstations.

Today, virtualization capabilities continue to expand. Recently, Microsoft announced the new NVads A10 v5 instances in Azure, built on the NVIDIA A10 Tensor Core GPU. These new instances bring greater flexibility and a lower cost of entry for accelerating graphics workloads in the cloud.

Built on top of NVIDIA RTX vWS technology, the NVads A10 v5 instances can support powerful virtual workstations. GPU resources can be scaled up to a whole A10 GPU, or across multiple GPUs for more demanding workloads like complex CAD modeling, simulation and rendering.

Immersive Experiences Help Elevate Manufacturing Workflows

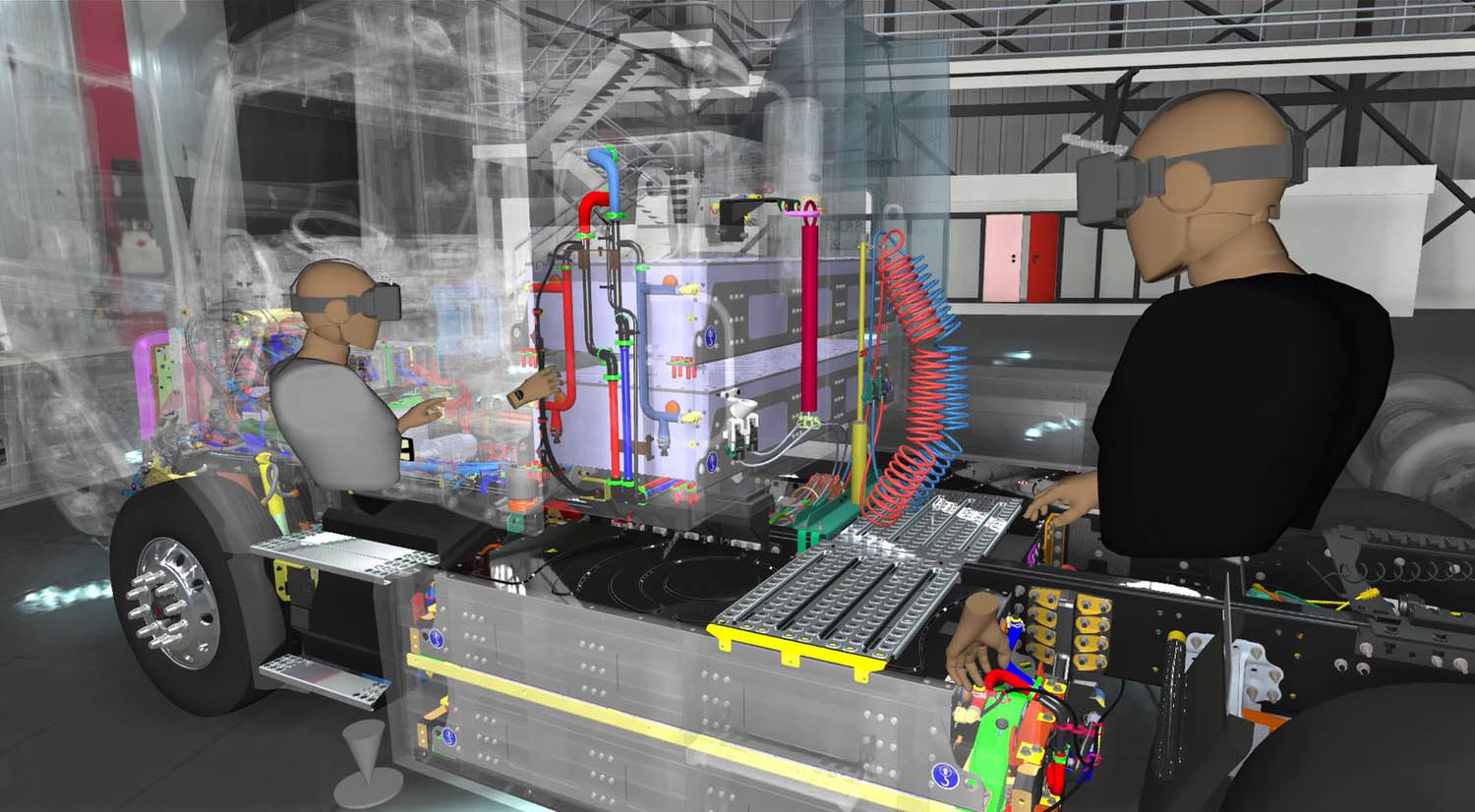

Streaming immersive experiences from the cloud offers many benefits to designers and engineers. Using XR can help speed up the prototyping process, as teams can create realistic 3D mock-ups in virtual reality.

And NVIDIA CloudXR is making high-quality XR streaming more accessible through streaming from the cloud. Using CloudXR, enterprises can deliver photorealistic virtual products and engaging XR experiences to any VR device, all while lowering costs and increasing efficiency.

Volvo is using NVIDIA CloudXR to deliver immersive experiences of products from anywhere in the world — this enables the team to stream virtual prototypes of new products to any XR device. CloudXR helps the Volvo team connect global engineering centers and production stakeholders from different locations into a common shared interactive virtual review. This eliminates the need for full-sized, physical mock-ups during the early stages of product development and planning, which helps reduce costs while accelerating production schedules.

Learn more about enhancing design workflows with NVIDIA solutions.