DutchAero, an autonomous part of the Italian aerospace company Avio, produces aero engine parts at its 2,000m2 advanced machining facility in Eindhoven.

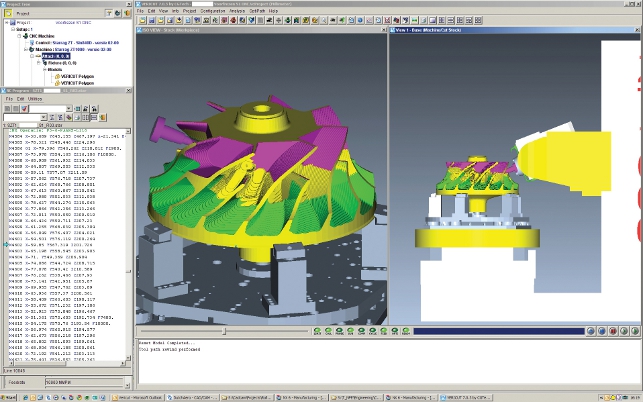

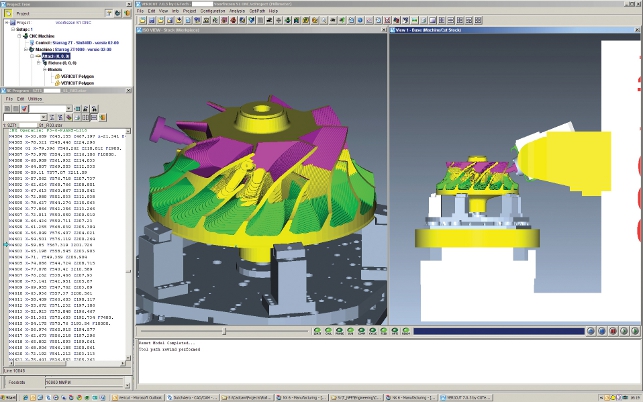

The NC code for an aero engine impeller gets the Vericut treatment

Manufacturers including GE, Rolls-Royce and Snecma in Italy all rely on DutchAero’s support in both civil and defence projects. “For example, we produce components for the F136 engine for the Lightning II joint strike fighter aircraft. These are fairly significant components with machining cycle times covering multiple shifts,” explains Patrick Delisse, HSM CAM engineer.

In the mid 1990’s DutchAero started to produce more complex aluminium structural parts and so invested in more complicated machine tools. It also installed Vericut NC code verification software from CGTech. “We needed Vericut to provide confirmation of the error free programming of the tool path, to protect both the raw material/component and the machine tool,” says Delisse.

CAD/CAM data comes from the company’s Siemens NX (Unigraphics) software, while Vericut provides an independent verification and simulation that the toolpaths run gouge-free and that the machine’s axes movements do not cause any collision between its structure, the workpiece, fixturing and cutting tool.

Simulation support

Machine simulation is very important for DutchAero and the latest machines installed, a Breton 5-axis turnmill machine and a StarragHeckert STC 5-axis machine, are all modelled in Vericut. CG Tech created the latter, while the machine supplier provided the model for its machine and Delisse added the dynamics.

“We used to do all development in house, but these days we work in close cooperation with suppliers,” says Delisse. “With the functions of a 3-axis it wasn’t too complicated, but for 5-axis it becomes very complicated so we rely on CGTech for simulation support.”

DutchAero’s large Pietro Carnaghi VTL is also modelled in Vericut. As this lathe can change cutting heads from horizontal to vertical, Vericut is able to get the tool in the correct orientation to completely simulate any machining operation it carries out. Tool management software comes from WinTool and the cutting tool assemblies are modelled as accurately as possible for use in Vericut.

Delisse uses Vericut interactively on his PC. “I run Vericut from line to line until it encounters an error, which is modified and stepped to the next error, and so on,” he explains. “Finally, I restart Vericut and run it through again to ensure the code is problem-free. I usually do this overnight so when I come in the following day and the code is all correct, it can then be issued to the shopfloor.”

Optimisation software

DutchAero also uses CGTech’s Optipath machining cycle time optimisation software, which adjusts NC program cutting speeds to make the machining process faster and more efficient. The software works on a simple premise.

Based on the amount of material removed in each segment of the cut, it calculates and inserts improved feed rates where necessary. In areas of light material removal, Optipath speeds feed rates and decreases the feed rates as more material is removed. Without changing the cutting tool trajectory, the updated information is applied to a new tool path.

Cutting down cycle times

Optipath is selectively used and, according to Delisse, judgement calls are made on which parts to run through Optipath.

“Some project parts have been running for a couple of years, even a small reduction in the cycle time provides a worthwhile return as you keep on making that saving,” he says.

“Usually we shave a significant percentage off the machining cycle times. And, it’s not just the time that we save it is also the cutting tools and the reduced stress on the structure of the machine tool. Generally tool life is extended when a NC program has been optimised and more often than not the surface finish is improved.”

www.cgtech.co.uk

www.dutchaero.nl

DutchAero hits new heights with Vericut’s machining optimisation module