With its advanced capabilities and multicore processing, Al Dean knows that simulation will soon be driving the product development process. What he didn’t realise was how pervasive it had already become

Over the past two issues we’ve run a lot of simulation-related coverage in the pages of DEVELOP3D. From advanced crack propagation and co-simulation to multi-core processing and the rise of the GPGPU (General Purpose Graphics Processing Units), it’s clear there have been some huge advances in the world of simulation and analysis. But this hasn’t been limited to advanced users. Simulation has gone mainstream.

Take, for example the new parametric design studies now within Inventor. These can use a combination of motion simulation, Finite Element Analysis (FEA)and design study optimisation to ensure designers and engineers are using the most efficient number of scenarios to get to an optimal design. The very idea that you can do all this, with a tool that costs just over six grand is quite something. And this is commonplace, rather than the exception.

Thinking back to when I used these tools in anger, you’d probably be looking at something in the region of thirty grand’s worth of software, running on a hardware platform costing a further twenty. I’m also aware that this last sentence probably makes me sound like the grumpy old fellow in the pub waxing lyrical about “How it all used to be better in the good old days.” – and it does – but with one big difference. It wasn’t better in those days. It was crap.

The software was hard to use, quite often command line driven, and the hardware was so scarily expensive that you’d save up for one SGI workstation and never be able to afford to upgrade it. In fact, you needed to book the pallet truck from old Frank in the storeroom, just to move it out from under your desk so you could install four grand’s worth (256K) of RAM.

Contrast this with today’s environment and near-future technology. We’re looking at multi-core workstations, up to a colossal eight cores as standard, and that’s before we even start thinking about using graphics cards to solve additional simulations. Sat beneath our desks some of us now have enough computing horsepower to effectively use simulation tools as an integral part of the product development cycle. Not just as a sanity check at the end of a project, but a fully integrated part of the process.

If you have the power to do the calculations as you design, you can use optimisation routines to find directions for design that you might never have conceived of. The tools are there, they are affordable and unlike systems of old are becoming more and more usable by the designers and engineer, as opposed to the specialist. But is it gaining traction? It certainly appears so.

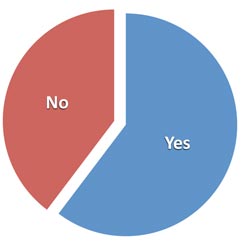

Are you currently using simulation?

We recently did some research into simulation usage amongst our readership and discovered something rather interesting. According to the results, a whopping 60% of you are already using simulation in some shape or form within your working practices and a good percentage are looking to adopt it in the very near future. Of course, there are always those involved in design, engineering and manufacturing for whom simulation holds no benefits, but it’s clear that the message is getting across and these tools are actively being used.

Another interesting discovery is what these tools are being used for. There’s always been a long held belief that simulation is used when products fail – to find the reasons for failure and to make post manufacture design changes – but this has changed. Validating a design variant prior to manufacture was the leading reason, closely followed by reducing physical prototypes and gaining insight into product performance. The old “fix it when it’s broke” reason came in last.

Perhaps the most gratifying statistic was who exactly was doing this type of work. Was it still the last bastion of the mesh-head, the big brain in the corner, with all the knowledge required to “do simulation.” It appears not. 78% of simulation work is now being done by designers and engineers, with only 20% carried out by the simulation expert, and a small fraction outsourced to a specialist.

While we would love to believe that our readers are much more advanced than the average designer or engineer, the key indicators can’t be ignored – simulation is everywhere. And with more and more processing power available on the desktop, all the pieces are in place to truly make simulation an integral part of the product development cycle to help create better products faster.

One question we didn’t ask in our survey was this: If you’re not currently using simulation to its full potential, can you really afford to be left behind?

Al Dean is Editor of DEVELOP3D Magazine. He nearly broke his office chair from the shock of reading the positive results of our simulation survey. If only his chair designer had learnt about simulation in DEVELOP3D.

{encode=”al@x3dmedia.com” title=”al@develop3d.com”}

Al Dean urges you to use simulation to its full potential, or get left behind