There’s been a lot of discussion about the rise of Direct Modelling in the pages of DEVELOP3D this past year. Ever since Siemens launched Synchronous Technology in the Summer of 2008, there’s been a renewed interest in non-history based modelling methodologies all across the industry.

IronCAD has been there from the very beginning and since its inception as Tri-Spectives a decade ago the system has proved that there is a viable alternative to history-based processes. Its flexible modelling technology allows users to define design intent with ease and uses feature-based modelling to great benefit. The product has evolved over the last few releases to grow into an impressive modelling system. Its approach has always been highly interactive, using a combination of direct manipulation of geometry, standard forms and user defined features to enable users to get their thoughts down digitally in the shortest time possible.

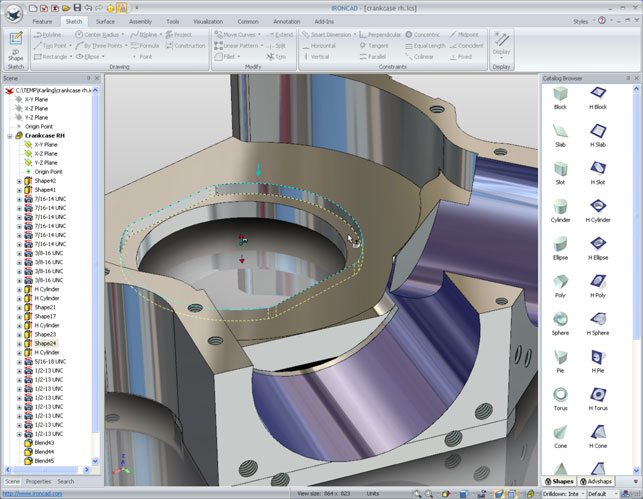

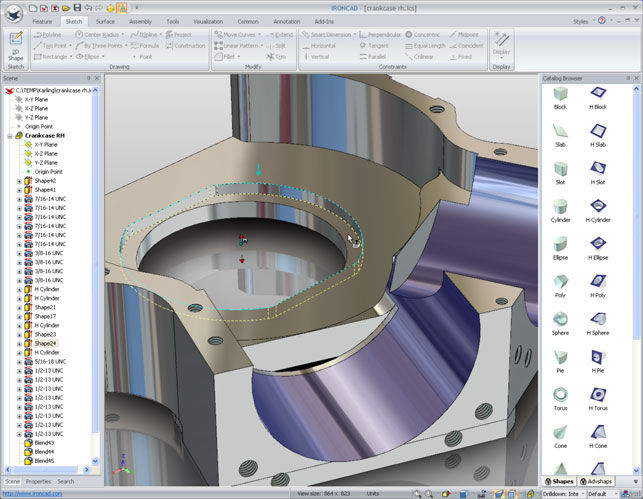

IronCAD Next Generation incorporates history-based modelling alongside direct modelling. Both use the same dynamic feature editing tools, allowing the drag, drop, snap and positioning of geometry

The fact that IronCAD contains not one, but two modelling kernels has also set it apart. The use of both ACIS and Parasolid within a single application is still something unique to IronCAD. This can bring benefits in problem modelling situations. If one can’t build the geometry, the chances are the other can.

With ACIS and Parasolid under the hood, plus PTC’s GraniteOne technology, the other huge benefit is that IronCAD has a very rich native data translation capability, allowing users to work with geometry from a much wider set of systems and with a much reduced chance of error.

Historically, IronCAD hasn’t seen the mainstream success of other modelling systems – but this has begun to change somewhat in the last few years. IronCAD is now part-owned by Chinese software solution power house CAXA and the system has been growing in adoption in the company’s home market. This has lead to increased development resources and funding and the next release looks to bring the company from one of the ‘also rans’ to perhaps achieve a bigger place in the grand scheme of things. The irony is that this release sees a new direction for IronCAD.

While IronCAD has been distinctly non-history-based for years, the next release, entitled IronCAD Next Generation, sees the introduction of a history-based modelling approach for the first time. Alongside this, there’s been an overhaul of the interface and extensive work done to bring greater tools for downstream processes, such as drawing and annotation. So let’s dive in and have a look.

In recent years while it may have been considered one of the minor players, this could be set to change with the Next Generation of the product

A new look

The first thing that’s noticeable is the adoption of the Windows Ribbon interface scheme. While there are still the IronCAD favourites, such as the catalogues to the right hand side of the screen for standard features, parts, and rendering materials, the system now looks much fresher and more modern. Commands are segregated into panels for sketching, features, surfaces, assemblies, visualisation (for display states and rendering), annotation and add-ins. Each is logically ordered and you’ll find that you adapt to the ribbon with ease.

Adding history

With the introduction of the new history plus feature-based approach, users now have to make a decision when starting work – whether the part lends itself to a feature history based approach, where each action is recorded and available for editing, or is suited to the world of direct modelling. This decision depends on the form of the geometry and the experience of the user, but as a rule of thumb, complex shapes lend themselves to a history-based approach (where feature shape may become obscured, meaning editing might be problematic), whereas more prismatic parts, where feature forms are maintained lend themselves to a direct modelling method. Whichever route is chosen, the user still has the same highly dynamic method of dragging and dropping geometry features, faces and edges that IronCAD mastered some years ago. And if the sketch/build feature/repeat method is preferred, the two can be mixed and matched within the same design environment.

New draughting tools

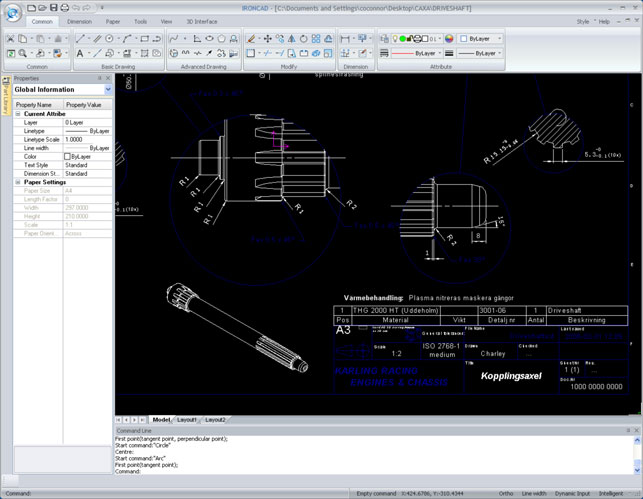

Alongside the huge change to how part and assembly geometry can be constructed, this release also sees a change in how IronCAD handles drawing production. In previous releases it used some home-brewed technology to build up a drawing environment. While it was perfectly capable of producing production-ready drawings, with all of the annotation and documentation required, the deal with CAXA gave IronCAD a more advanced tool that’s sold very well in the Far East. CAXA is known for its CAXA Draft application that brings a complete and extensive set of draughting tools, working as you would expect from any modern 2D CAD system.

The introduction of a fully integrated version of CAXA Draft sees IronCAD’s existing drawing capabilities extended

The IronCAD team has integrated this application directly within the IronCAD interface making that rich set of tools available to its users. This provides a fully-integrated, bullet proof drawing system that allows 3D parts and assembly geometry to be used for the creation of documentation required to move a product into production. It follows a similar user interface style to many of the leading 2D design tools on the market today. Alongside this integrated 3D/2D approach, adoption of CAXA draft also means that IronCAD can now offer it as a standalone application, for those looking to maintain separate 3D and drawing seats within their design office.

Conclusion

IronCAD is adapting to changes in the industry. While the system has always taken a direct modelling approach, the addition of history-based techniques changes the game somewhat. In recent years while it may have been considered one of the minor players, this could be set to change with the Next Generation of the product. The relationship with CAXA in China is obviously paying dividends as development resources are clearly being made available and the introduction of CAXA Draft into the main IronCAD system is a clever move. But when you’re looking at technologies such as this, you also have to consider the financial benefits.

The new User Interface brings the Ribbon to IronCAD, but the core parts of the system remain, such as the standard features Catalog to the right of the screen

IronCAD costs $3,995 per license. For that cost (which is a straight exchange from US dollars), you receive all of the core system functionality, but in addition, as part of the launch of Next Generation, IronCAD will also provide an additional license of CAXA Draft free of charge that can be used alongside it (or installed on a different machine as it’s not tied to the host IronCAD license). There is a much lower cost version of IronCAD, called Inovate, and this is a pure modelling system costing $1,295, which represents great value for money.

So, what does the introduction of history-based modelling mean for IronCAD? There’s a huge resurgence of interest in direct modelling at present and almost every vendor is jumping in with its answer. Autodesk has its Fusion Technology preview, Siemens has Synchronous technology, PTC acquired CoCreate and you’re seeing the filtering of direct modelling, history-less modelling introduced into Pro/E. Finally rumours have it that the next release of SolidWorks will have more direct modelling tools.

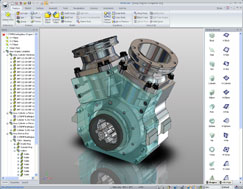

IronCAD is quick at creating mock-ups of products

I’m convinced that a combination of Direct and History-based modelling represents the future of 3D design. The two, seemingly disparate approaches will merge over the coming years in release cycles from every vendor. What’s interesting is that IronCAD is starting from the opposite end to most. It has mastered direct modelling and the introduction of history-based modelling can only serve its users better, giving them the freedom to work how they want.

If you’re looking at Direct Modelling as a potential weapon in your armoury, then IronCAD certainly has an impressive wealth of tools at your disposal. There will be a trial version of IronCAD Next Generation available on www.ironcad.com shortly and I’d encourage you to take a look.

History and non-history in practice

Karling Racing has been working with IronCAD Next Generation since the beta release and the company has been using the history and direct modelling tools on the development of the world’s fastest Harley Supertwin, which packs a breathtaking 2,000 horsepower.

Anders “Charley” Karling, owner of the Swedish company, shares his experiences, “When we set out to build the world’s fastest Harley Supertwin, we needed to be flexible in our thinking and dynamic in our approach to design. Throughout the development process and later in testing at the track, we had to make radical changes sometimes completely rethinking our approach to a problem. IronCAD’s dynamic approach to design was the only tool that allowed us to make those changes quickly and on the fly.”

“Today, things have settled down and our design is at the leading edge. We are fine tuning to ensure that we stay at the top of our game. To help us do this, we now embed more design intent into our models, today we have a lot more data about how changes should impact other parts around them, and we now want to build that intelligence into our core model data. IronCAD’s unique combination of history-based and direct modelling is the only product on the market today which allows us to achieve this.”

| Product | IronCAD Next Generation |

|---|---|

| Company name | IronCAD |

| Price | $3,995 |