Targeting the revolution in automotive electrification, the latest release of Simcenter from Siemens Digital Industries Software has added multiple new updates, as well as new capabilities for sectors like aerospace and additive manufacturing.

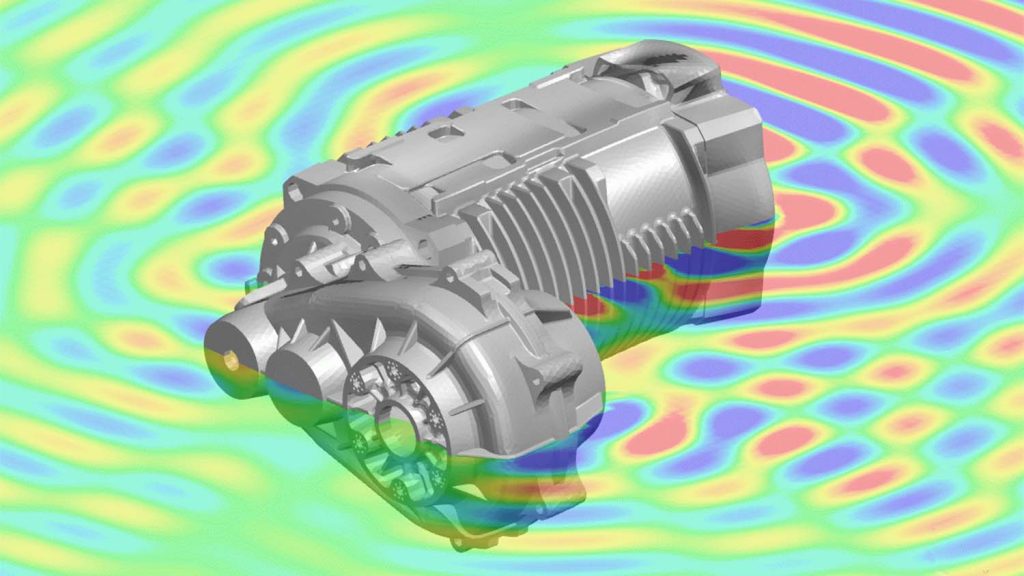

The development of new Electric Vehicle (EV) powertrains tend to be broken into silos for e-motor design, transmission analysis, NVH and acoustics, with Simcenter mechanical simulation tools looking to break down these silos by helping critical load, design and model information to flow between each.

Beyond EV powertrains, there’s additional improvements for the simulation of other automotive applications, from NVH to tires.

Even windscreen wiper performance sees an update, with a new contact pattern display in Simcenter 3D helping analyse wiper contact patterns across the glass. By modelling the wiper as a flexible body combined with contact elements, Siemens says the new contact pattern display will show easy to interpret results of the wiper forces across the windshield.

This should let the user to learn how consistently or inconsistently the forces are distributed and if the wiper design is working as expected, without the need for costly and time-consuming physical testing.

Simcenter Tire software has an updated road contact algorithm to reduce the large amount of road data exchange required to build high-fidelity tire models required for driving simulators and hardware-in-the-loop set-ups. This means that computational performance should be increased by up to 45 per cent, enabling the use of high-fidelity tire models in real-time applications.

“Addressing complex engineering challenges such as developing products that are more powerful, yet greener, lighter yet stronger requires a fully-integrated CAE solution,” said Jean-Claude Ercolanelli, senior VP of simulation and test solutions at Siemens Digital Industries Software.

“The latest release of Simcenter offers a host of powerful enhancements to help engineers meet those challenges efficiently and significantly faster than ever before, whether that is getting tire contact simulations solved 45 per cent quicker or reducing airframe structure preprocessing by up to 80 per cent.”

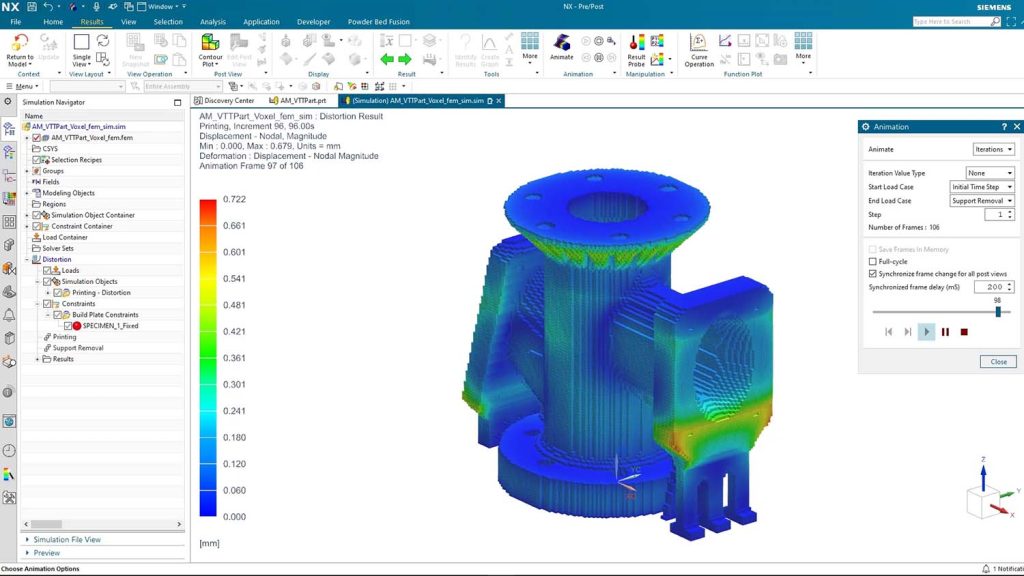

For additive manufacturing, Simcenter has added a simplified application for simulating the powder-bed fusion (PBF) build process that it says is easier to use for engineers without in-depth CAE expertise. Using a voxel-based mesh in the background it can quickly model and simulate the PBF build process, allowing engineers to gain a good understanding whether a part will build successfully. More detailed analysis can then be performed by CAE experts also using Simcenter 3D, enhancing collaboration.

Following on from the introduction of the ability to launch simulations on remote HPC systems directly from within Simcenter 3D, engineers now have the ability to review simulation results directly from the Remote Simulation interface. This helps engineers determine if simulation studies ran correctly before transferring large results files back to a local workstation for in-depth evaluation.

For the Aerospace industry, new capabilities reduce the number of models needed to simulate the behavior of thin aircraft skins and perform margin of safety calculations faster than ever before. In addition to the new improved airframe applications, Simcenter is looking to help engineers better understand rocket launch dynamics by simulating the liquid sloshing in fuel tanks. While not limited to aerospace and rocket applications, liquid fuel sloshing dynamics will benefit from a new incompressible fluid model to predict slosh frequencies and hydro-elastic modes.

In other industries, this can also be used for evaluating sloshing in cargo, ballast or fuel tanks of large ships, automotive vehicles, rail cars and much more.

New standard calculation templates have also been added to the margin of safety analysis tools within Simcenter 3D. These automatically prefill all the inputs based on a set of rules so the engineer just needs to select the geometry to apply calculation to – removing the traditional reliance of custom script development and the associated maintenance costs.

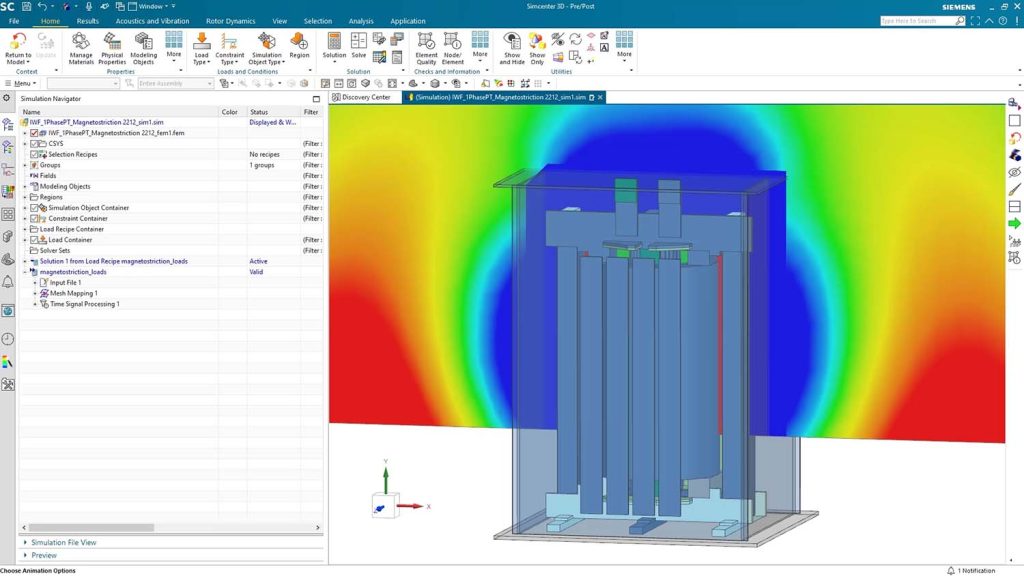

For the industrial machinery sector, where machine uptime is the prime driver, Siemens is positioning Simcenter to help with durability prediction without the need for specialist knowledge. Simcenter 3D can now automatically calculate the parameters needed to adhere to the industry standard FKM guidelines, letting engineers conduct durability analysis directly from their stress analysis results, to ultimately help machines meet operation requirements.

The software can now also simulate the complex multi-disciplinary magnetostriction effects that cause transformer noise, with the forces calculated able to be used both for noise and vibration assessment allowing electromagnetics and acoustic performance simulation within a single environment.