Materialise and Ansys have partnered in a move to enhance 3D printing software Magics with Ansys’ simulation capabilities, reducing the lengthy times needed for data transfer.

In many cases, the AM process requires users to perform build and data preparation tasks on one software platform and run simulations on another. Build defects caught by simulation within Magics will remove the need for data transfer between tools to update build files. This ultimately requires users to master both platforms or transfer information to a completely different user, creating disconnected workflows and eliminating the scrap-saving benefits of simulation.

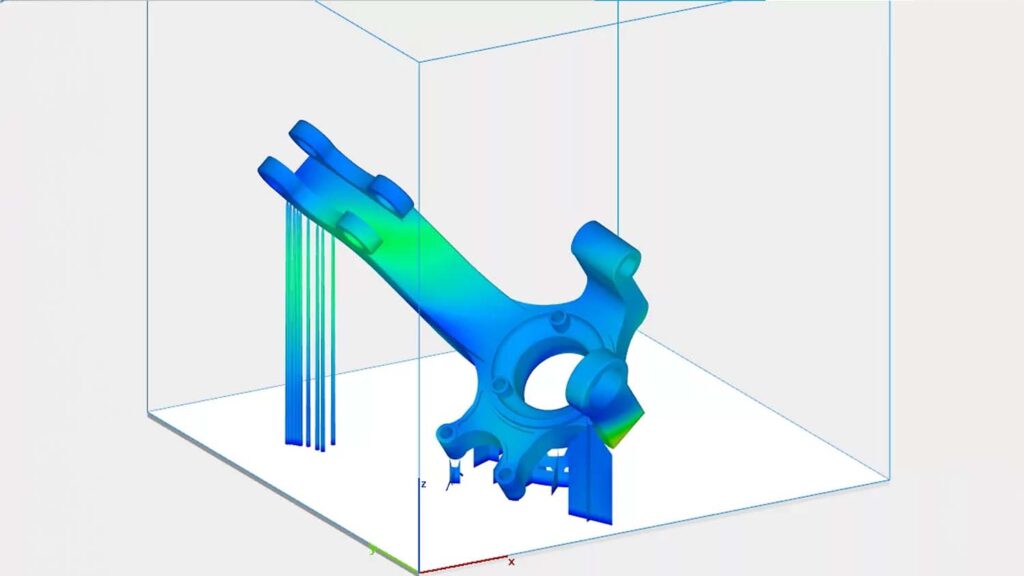

This new partnership will integrate Ansys Additive Suite into Materialise’s data and build preparation tool, Magics.

Materialise says that as a result, its workflow will deliver more value to Magics users by providing access to Ansys software, enabling R&D teams to prepare AM builds and run best-in-class simulations all within the same interface.

“Improving accessibility to simulation is an important step to support our customers in their metal 3D printing,” Materialise CTO Bart Van Der Schueren. “Our goal is to enable a smooth design process by empowering users to seamlessly run valuable and efficient detection and correction simulations in tandem with build and data preparation.

“This partnership will do so by providing a platform for innovation and a process by which users can 3D print quality products with confidence.”

Ansys senior VP of products Shane Emswiler, added: “Simulation changes the way we perceive our interactions with the world. Whether it be understanding the behaviour of new material or revisiting standardised product configurations, the adoption of Ansys technology into the AM workflow signifies the necessity and utility of simulation throughout all levels of the product life cycle.”