The design, development and analyses of thermal fluid systems, as found in the power generation, aerospace, oil and gas industries, are often a complex and costly business.

The sheer scale of the projects is huge and the risks, both in terms of finance and safety, are massive. With this in mind it is essential to get things right, first time, and careful planning is essential.

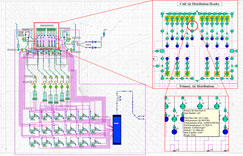

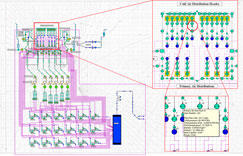

Integrated simulation of coal fired power station

A combination of technologies is typically used to design these complex systems. When designing a new power plant for example, one usually starts with a concept design to determine the impact of process conditions and cycle lay-out on efficiency and power. The next level of analysis is to improve the accuracy by taking piping losses, compressor and turbine efficiency and secondary flows such as leak or bleed flows into account.

The greatest detail and accuracy is obtained though the analyses of sub-systems such as the boiler, reactor or heat exchangers using Computational Fluid Dynamics (CFD) codes.

The problem is this process is usually disjointed between the concept and detailed 3D based CFD analyses and often means that designs are conservative, and redundancies and inefficiencies are built into a system. Concept design tools are too high level, while CFD simulation tools are often too complex and too time consuming to be used efficiently.

Looking to bridge the gap between these technologies is a product called Flownex. Sold in the UK by Athena Horizons, the software offers system-level design, simulation and optimisation of thermal fluid systems in a single integrated environment. The system works by linking together ‘intelligent’ component models in a network to represent a complex system and then using the software’s algorithm, which resembles that of a conventional fundamental CFD code, to analyse and optimise it.

The workflow

The engineer starts by creating a schematic to map out the system CFD thermal fluid network. This is done by dragging and dropping components and nodes into the ‘drawing area’. Flownex comes with a huge library of components including heat exchangers, heat transfer components, discretized piping runs, restrictors, turbos, pumps, and power specific items such as those found in the nuclear and power generation industry. Custom items can also be created using a full parser and compiler for writing Microsoft C# code. Flownex also boasts a control and electrical library, since no large plant functions without PLCs, controllers and electrical components like breakers and switches.

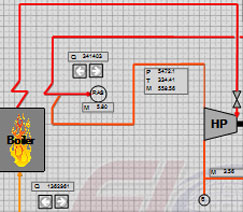

Coal fired boiler draught plant simulated from the air intakes, through the primary and secondary air sides, taking induced and forced draft fans into account, through the mills, the boiler and out the back to the smoke stack

With the nodes and components in place the next stage is to add boundary conditions. For example, the pressure or temperature at any point in a network.

Once the network is defined a working fluid needs to be assigned. In addition to a wide range of gases, gas mixtures and liquids, the system is able to work with homogeneous two-phase fluids. In reservoirs for example the level of the fluid in the tank is calculated as part of the results.

In terms of analysis, Flownex can solve both steady-state and dynamic problems and the feedback of results is extremely quick. These can be viewed in a results table, on graphs or can be summarised in pre-defined Excel reports. A number of charting and visualisation tools are also available.

The power of the system comes into play when the engineer starts to experiment with the integrated components and work through a balancing and optimisation process, providing valuable information regarding the impact of different component designs and operating conditions on the overall plant performance. This not only helps to identify any bottlenecks in the system, but helps ensure that the system is as efficient as possible.

Because the solver can provide accurate results in near real time and Flownex are also being linked to actual plant SCADA’s in creating full scope industrial plant simulators. Experimenting with different options is simple, which makes it easy to optimise the network to achieve the best possible solution and identify any uncertainties and their effect in terms of risk, safety, delays and cost.

Conclusion

In summary, Flownex is a simple, but effective tool for system CFD thermal fluid network design and optimisation. It takes the simplicity of a generic schematic design tool and backs it up with solid engineering calculations all in the same environment, integrated with controller and electrical components. Then, if the engineer wishes to increase its power and extend its reach further, it can also be integrated with actual plant controllers to bring the actual interlocks and control response into the engineering model that can be used for example to evaluate control philosophies and operator procedures.

| Product | Flownex |

|---|---|

| Company name | Flownex (Athena Horizons) |

| Price | from £6,000 |