The use of new Digimat simulation tools should be of interest for Stratasys’ Fortus 900mc users looking to target production manufacturing

Part of the Hexagon Group, MSC Software has continued to expand its simulation expertise into the world of 3D printing with industry heavyweights Stratasys and Materialise.

Although both differ in the materials covered, both look to take advantage of advanced simulation technologies to conquer potential build errors.

Stratasys is collaborating with MSC’s e-Xstream Engineering, an advanced tool for multi-scale modeling of composite materials and structures, to deliver high performance process modeling and structural analysis numerical tools.

Central to the collaboration is the objective to develop predictive simulation solutions for Stratasys’ Fused Deposition Modeling (FDM) technology to enable the production of tighter tolerance, higher performance parts.

This is aimed at being achieved in conjunction with e-Xstream Engineering’s standalone material modeling platform, Digimat, which offers a self-contained module to enable a flexible interface that is accessible for basic to advanced level designers, as well as other users across multiple manufacturing based workflows.

Core functions of its collaboration include process simulation applied to the design-to-3D-print workflow to achieve the high accuracy and repeatability required by manufacturing users of its production FDM printers.

The software will help predict and mitigate part warpage as well as realise the impact of design decisions on the manufacturing process before the part is produced.

Further to the collaboration, the next release of e-Xstream’s material modeling platform, Digimat, will deliver the first material models of Stratasys’ Ultem 9085 resin, with a complete process package for its Fortus 900mc 3D Printer.

Customers are provided the numerical tools necessary to perform both process simulation and structural analysis by feeding critical process information from Stratasys’ pre-processing software, Insight, to Digimat’s AM module, available for download at the end of November 2017.

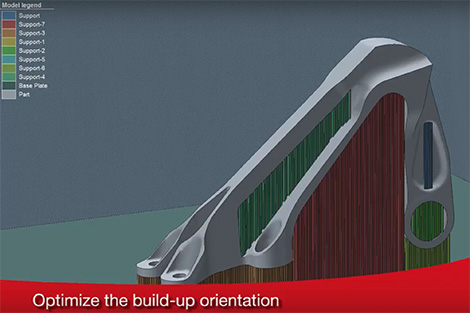

MSC’s Simufact will aid positioning of support structures for metals 3D printing

Materialise, however, is looking to take advantage of MSC’s Simufact simulation expertise for metals, within its Magics Metals module for data preparation and support generation.

As a result, the support structures in the Simufact Additive software will be represented with Materialise Magics features.

“When it comes to optimising the build process based on simulation results, the support structure plays a significant role in achieving first-time-right print results,” explained Dr. Hendrik Schafstall, CTO at Simufact engineering.

“Our customers will benefit from Materialise’s leading representation of support structures integrated in Simufact Additive, further strengthening our simulation process chain.”