How SimScale FEA simulation was used to analyse multiple temperature contours for a surveillance camera design faster than they could be prototyped, avoiding issues that would likely not have been uncovered until the product made it to market

Spark, an Italian surveillance technology company, has been producing innovative CCTV camera designs since 2012, pushing the robustness and reliability of its products both inside and out.

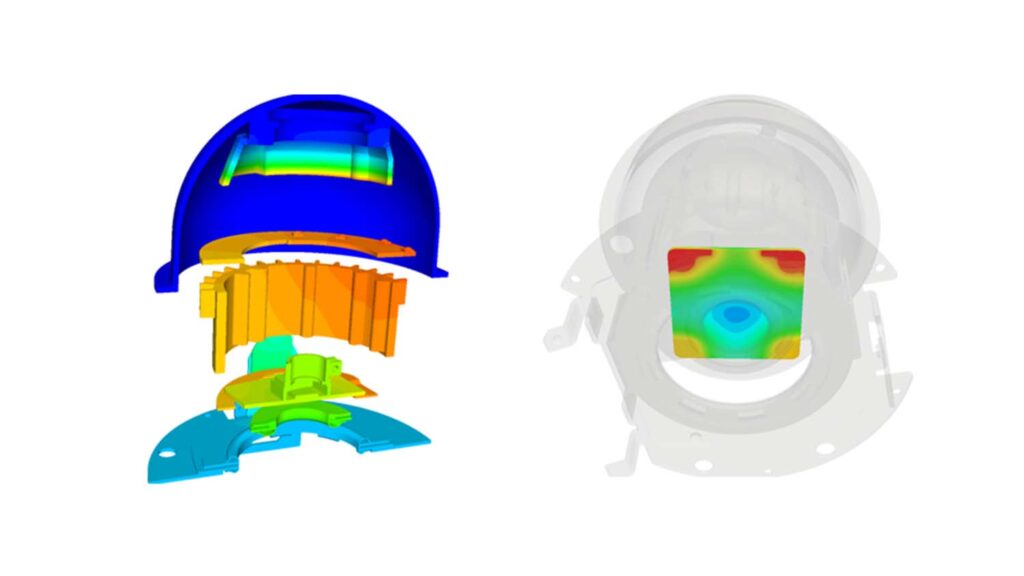

When considering adding infrared LEDs to its Mira camera to enable night vision, Spark wanted to analyse the temperature contour on the heat sinks and on the image sensor board for each of their design versions.

This way they could determine which of their designs best matches the required operating conditions and as such could move into physical prototyping.

The project involved running transient SimScale FEA heat transfer simulations to analyse the temperature distribution on a surveillance camera considering heat generation from both the LEDs inside as well as from the image sensor.

Two design approaches were validated, considering different heat sinks and different convection configurations.

In order to be able to assess the temperature contour over time due to the different heat sources inside the camera, Spark technical product owner Massimiliano Marchionni ran four different transient heat transfer analyses.

The CAD was then meshed using the automatic Tet-dominant algorithm available through SimScale’s HPC-powered cloud simulation platform, which created meshes with around 1.2 million nodes.

The design validation was then performed for two setups and for two different camera designs with the help of a transient heat transfer analysis type.

The main purpose of the simulation was to assess the temperature distribution on the heat sink which is located inside the device – its role being to dissipate the heat generated from the LEDs.

The other goal behind the simulations was visualisation of the temperature distribution on the image sensor’s board and how it is affected by the heat dissipated from the heat sink and the other camera components.

Each simulation contained two different volumetric heat sources, one assigned to the LED and the second one on the image sensor.

All air exposed walls were assigned a boundary conditions that modeled convective heat transfer to the exterior, taking into consideration different transmissibility coefficients.

The simulations were then performed for a gap time of 1,500 seconds and with 32 cores. Each one took on average around 130 minutes to complete.

The simulations were then performed for a gap time of 1,500 seconds and with 32 cores. Each one took on average around 130 minutes to complete.

The possibility to assess the heat sink configuration early in the design process was of great value to Spark, allowing them to speed up the development with simulation earlier in the design stages.

“We are using SimScale FEA simulation to drive mechanical decisions during design time,” said Marchionni from Sparks’ headquarters in Reggio Emilia, Italy.

“Our mechanical engineers use SimScale to test new solutions and to choose the one with a better heat distribution. In particular, we are not interested to estimate the exact temperature in critical areas but instead, we use SimScale to find bottlenecks in heat dissipation and to confirm our thermal solutions by comparing different 3D models and different materials.

Marchionni continued: “The real value of using SimScale comes down to the working days we saved on managing thermal issues in case we would have found them first after mass production. I see SimScale as a form of prevention.”

By running all the four configurations simultaneously in the cloud, Spark estimates it saved 75 per cent of the time that it would’ve taken to run physical tests for the two initially proposed designs.