Altair has announced updated solver technologies and enhanced user experiences within the release of its 2021 simulation software update.

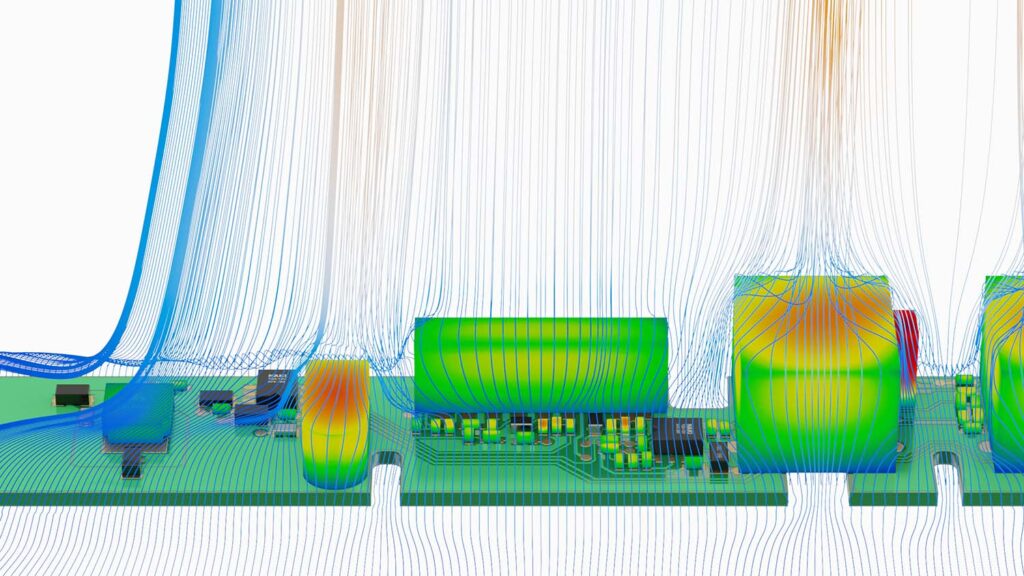

The huge range of updates is topped by the impetus on Altair 2021 for end-to-end electronic system design, to enable the design of smarter connected devices through all aspects of physical, logical, thermal, electrical, and mechanical design.

In the 2021 release, Altair says that it has accelerated a variety of applications in this sector, from more efficient printed circuit board (PCB) design review, verification, analysis, and manufacture to the design of motors, sensors, and actuators with simulation.

Notable Altair 2021 updates include improved simulation and optimisation of wireless connectivity, including 5G and electromagnetic compatibility; more capabilities for PCB fabrication, assembly, and end-of-line testing.

Additionally, expanded workflows, that aim to simplify and automate analysis of structural stress, vibration, thermal, and drop-test performance, have been built on for non-experts.

“In addition to accelerated simulation of real-world product performance and expanded simulation-driven design for manufacturing functionality, this release brings a robust end-to-end electronic system design toolset to our customers,” said Altair CEO James Scapa.

“The latest updates to our simulation solutions enable customers to develop complex products more profitably by simulating 5G connectivity, electronic board level performance, modern manufacturing processes, and more.”

All the simulation products are supported by the new Altair Material Data Center, which claims the largest number of plastic materials and properties available on the market.

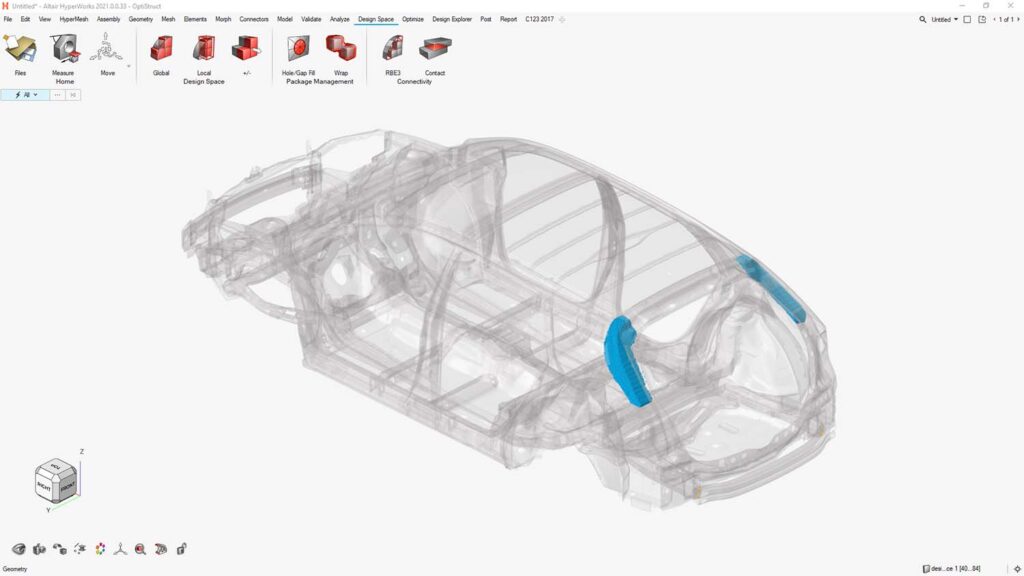

This will be a bonus for anyone closely following Altair’s simulation-driven design for manufacturing (SDfM), which has expanded for 2021.

The expanding functionality of Altair’s SDfM offering now spans casting, stamping, moulding, extrusion, additive, and foaming.