Schiebel has used the latest design technologies to optimise its aircraft, enabling its unmanned craft to go further than ever before. Stephen Holmes hears how Altair simulation tools helped get this optimised, 3D-printed design off the ground

Demand for unmanned air systems (UASs) has grown massively over the last decade, with significant advances made in both the range and robustness of vehicles.

Schiebel’s Camcopter S-100, able to operate both day and night, even in adverse weather conditions, and with a beyond line-of-sight capability of up to 200 km over land and sea, has proved to be one of the most versatile.

The Camcopter S-100’s vertical take-off and landing ability make it ideal for rough terrain and marine uses, including maritime patrol, fire and emission monitoring, supply line surveillance, airborne laser scanning and aerial cinematography.

To achieve this flexibility, the design of the S-100 perfectly balances fuel economy with toughness. Its carbon fibre and titanium fuselage allows it to reach altitudes of over 5,000m and to carry a 34kg payload, while staying airborne for over 8 hours.

From its headquarters in Vienna, Austria, Schiebel has engineered the S-100 to be as light as possible to increase the vehicle’s reach, optimising the design for performance, while ensuring airworthiness.

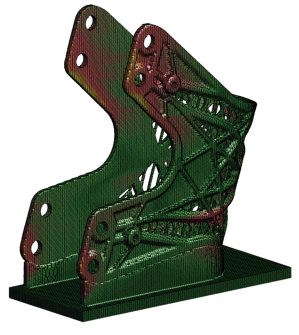

To ensure a perfectly tuned architecture and a lightweight design, while increasing stiffness and strength at the same time, Schiebel’s engineering team performed a wide range of simulations, especially to optimise the design of additively manufactured engine parts.

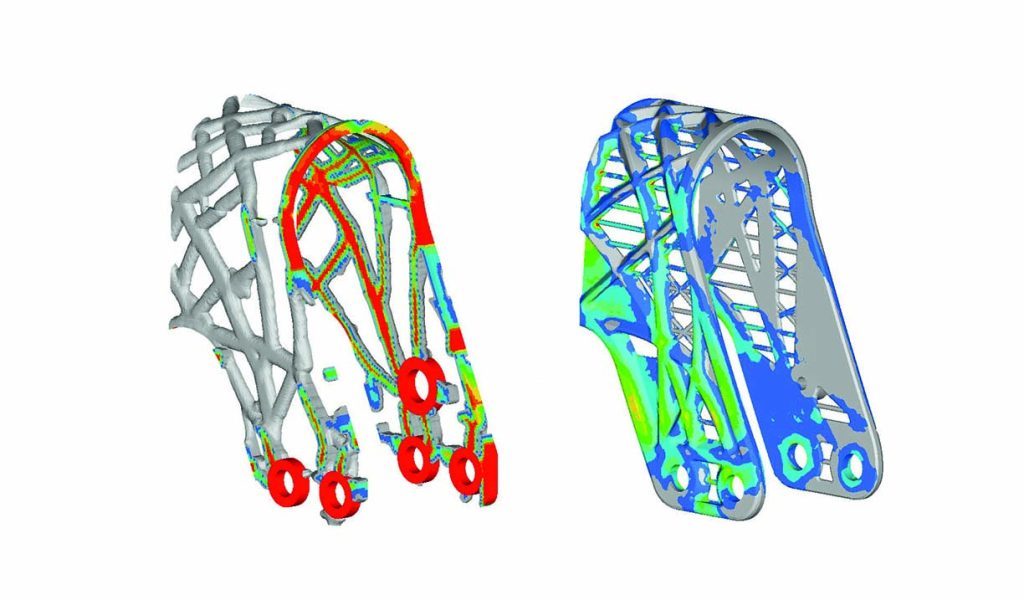

Using Altair’s topology optimisation structural design tool, the team has managed to reduce weight significantly while maintaining a high stiffness level. Subsequently, the system was evaluated for laminar and turbulent flow simulation, as well as conjugate heat transfer simulation using Altair CFDTM.

Schiebel – flight checks

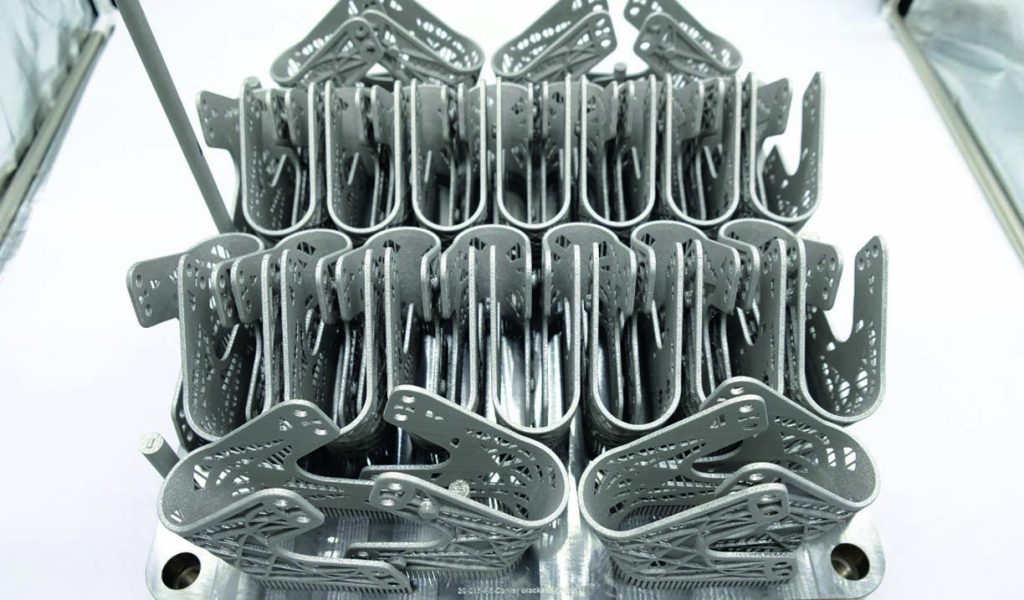

Since 2020, Schiebel has had in-house metal 3D printing capabilities. It uses an EOS M 400-4 metal 3D printer to manufacture landing gear brackets and titanium parts for its S-100 rotor engine, helping maximise durability and power output from the smallest possible weight and size.

To push the design for additive manufacture even further, Schiebel took advantage of its access to Altair Partner Alliance solutions and applied tools such as Additive Works Amphyon to simulate the AM process, including predeforming the parts to achieve the required accuracy of the end part.

Amphyon was also used for thermal stress simulation, allowing engineers to identify thermal hotspots and simulate the strength of the support structure. Members of Schiebel’s engineering team say that the combined use of additive manufacturing and simulation driven design has helped reduce the weight of components by up to 50%, while increasing stiffness and strength by the same amount.

Another major benefit of this simulation-led approach is a reduction in printing costs, as Amphyon simulations identify issues that might arise during printing before they occur, thus avoiding additional print jobs due to manufacturing defects.

“Altair solutions helped us create a topologically optimised engine part for our Camcopter S-100 and an efficient design that meets all demands. Using simulation enabled us to leverage the full potential of additive manufacturing and allowed us to accelerate our time to market,” says Schiebel head of additive manufacturing, Dominik Kohl.

“Thanks to Altair’s technology expertise and support, we are able to realise significant time and cost savings and offer our customers exceptional cost-benefit ratio.”

Every gram saved on the aircraft allows Schiebel to further increase endurance or payload capacity, keeping the company at the leading edge of aerial innovation and giving its designs the widest range of possible uses.