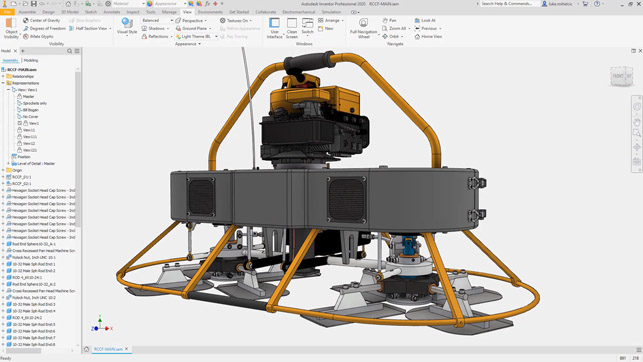

Al Dean looks at Autodesk Inventor 2020, and finds while the latest update might not be Autodesk’s primary focus these days while its younger sibling Fusion grabs attention, the company’s mid-range mechanical CAD product quietly continues to deepen and mature

In the mid-range mechanical CAD market, few systems offer the depth of functionality associated with Autodesk Inventor.

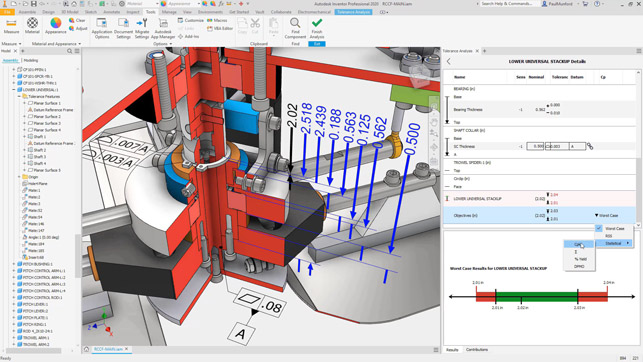

Through some smart acquisitions and a lot of integration work, Autodesk has built out a set of solutions that covers not only core design and engineering in both 2D and 3D, but also simulation, manufacturing and more.

With Autodesk moving to a more regular release schedule – one that features an annual update, along with three richer updates during the year – there’s usually a fair amount to check out. So shall we begin with Autodesk Inventor 2020?

Inventor has been freshened up for this release. Core functionality is the same, but the look and feel is a lot clearer, with core commands overhauled

User experience

Let’s kick things off with a look at the common elements in Inventor – the ones that apply to all customers, no matter what their use case or industry sector – and begin with the user experience and interface.

While Autodesk has always made a better-than-average go of keeping Inventor clean, fresh and up to date, particularly compared to some of its peers in the mid-range market, this release sees a pretty extensive overhaul of how the system looks.

While I realise that icon redesigns may not be the most enthralling of subjects, in this case, it seems perfectly valid. To understand why, we first need to bear in mind that today’s user environments are very different from how they were when Inventor was first released, almost two decades ago.

Back then, the desktop was king and designers and engineers didn’t expect mobility from their computing.

Fast-forward to today, and the mobile workstation is a big part of the picture and software is used in a wide variety of locations, environments and lighting conditions. If lighting isn’t great, the screen is hard to see. If software is too dark, the same holds true.

Because of this, Autodesk Inventor 2020’s introduction of a new ‘light theme’ will prove useful to many, as will the refresh of most of the icons in the system.

In addition, work that began during the 2019 release cycle to modernise core commands and move them into a single panel continues in this latest update. The goal here is to present all options and variables in a single, easy-tounderstand space.

While not every aspect of Inventor has been tackled yet, you’ll see improvements to the most commonly used operations, including extrude, revolve and sweep.

This is in addition to work already done on the hole command in 2019. While this work is being done, there’s also the opportunity to add in new functionality, such as the sweep operation now getting the ability to sweep a solid along a path.

This has been a popular update in many major systems in the last year and, rather than sweeping a 2D profile along a path, allows you to sweep a 3D geometric form to create the sweep.

At first glance, the differences here may seem a little esoteric, but when you think about modelling up complex linear/rotary mechanisms, where maintaining the form you need with a simple sketch isn’t going to work, then having a 3D form driving feature creation will pay dividends in terms of getting the functionality you want.

It’s also worth noting that by using a panel approach, Autodesk is also making these operations more flexible in their use – for example, with a panelised command, you’re now able to switch between the sketch and the feature without having to exit the operation first.

Finally, in terms of user interface and usability, this release sees the addition of improved support for multiple monitor set-ups. It’s now possible to drag a window out of the Inventor frame entirely, rather than trying to span it across two or more windows, and place it on another monitor.

While the ribbon doesn’t replicate (instead, it remains on the main display), this does let you have multiple documents open, with the model browser and other free-floating dialogues available in a useful manner.

Considering the prevalence of multiple monitors, I would imagine this is a much requested feature. Just remember to quit your current command before moving windows, otherwise it won’t work properly.

Parts & assemblies

Now let’s move on to part and assembly modelling. As you’d expect, Inventor has mature set of tools for modelling both.

The part modelling tools naturally include standard solid and surface modelling, but in recent years, they have also begun to include a good set of sub-divisional, surfacestyle, free-form modelling tools from Autodesk’s T-Splines technology (also found in Fusion 360). And in terms of assembly modelling, Inventor has a good range of tools to let you make the most of both creating and editing these forms.

Starting with part modelling, there are some really nice updates in 2020, in terms of pure geometric modelling. One example is the addition of a face unwrapping tool.

Inventor already offers tools within the sheet metal environment to help with unwrapping neatly folded parts, but this new functionality in Autodesk Inventor 2020 is going to be super useful when it comes to trying to estimate blank size and form – perhaps to help with tooling design for stamping dies, for example.

You select a set of continuous faces, and the system will perform an unwrapping operation. There are options to lock a specific edge set as linear or to mark a set of edges as rigid (to maintain a feature shape), though you can only do this to a single set of contiguous edges.

The end result is a profile that can then be used in downstream applications. While this operation doesn’t factor in any stretching of material, it’s a good for a quick first pass or for prototype runs.

Assembly design

As ever on the large assembly front, this wouldn’t be a CAD release without at least lip service being paid to performance.

For the Autodesk Inventor 2020 release, the focus has been on improving specific actions and operations, rather than speeding up load times.

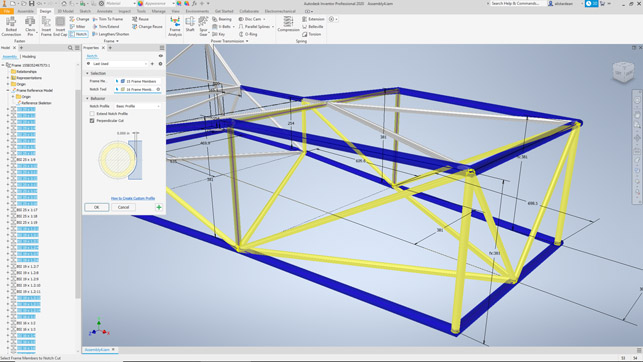

For those working with fabricated frameworks, for machine design, jigs/fixturing and so on, then the Inventor 2020 release is going to be a real time-saver.

While the Frame Generator tools have been in the system for many years now, they’ve not really seen much in the way of updates or enhancements – until this 2020 release, that is. While the core part of the system and its workflow haven’t changed – they use skeleton sketches to drive 3D frame design – the workflow will shorten, thanks to some new capabilities.

Essentially, the workflow follows the familiar path: you use a series of 2D and/or 3D sketches to create the reference for the framework and then either a library of intelligent standard forms or those you’ve created yourself, in order to quickly add in the rough elements for that framework.

The real improvements come into play once you have these constituent parts in place and start to focusing on finishing them – mitring them, creating mitre joints and notches, and so on. In previous releases, you had to work your way through each pair individually. This could take a considerable amount of time.

For 2020, however, this has been revamped. It’s now possible to create multiple joints in single operations.

To use the notch operation as an example, you select your frame members (those you want notched), then your notching tools (those whose form the members need to conform to) and the system does the rest.

There are options here for notching gaps and maintaining perpendicular cuts around the notch (ideal for CNC tube-cutting and shaping machines).

In conclusion

Autodesk is in a tricky position with Inventor. On the one hand, it’s got a fancy new system in Fusion, which it wants to promote as its future flagship. On the other hand, Fusion won’t satisfy everyone –and users engaged in more traditional engineering and manufacturing will still demand the richer, more mature and deeper toolset found in Inventor.

The fact that the Autodesk team has also just added Nastran, Nesting and a wealth of CAM NC programming technology to the associated collection only reinforces that commercial reality.

Yes, you might take a look at the updates to core Inventor and decide that, on the face of it, there’s not a huge amount of ‘newness’ there for the subscription money involved – but the truth is that we’re now at the point where workflow consolidation, new efficiencies and evolving existing tools is the order of the day, rather than swathes of brand-new technology.

And from this perspective, Inventor 2020 is a cracking release. Across the board, Autodesk has found ways to improve complex workflows, as seen in the updates made to Frame Generator, which could drastically reduce the steps needed to detail out and complete a complex framework.

Finally, let’s look at cost. At the time of writing, a seat of core Inventor costs £2,286 per year or £288 per month.

By contrast, Autodesk’s price for its Product Design & Manufacturing Collection, meanwhile, comes in at £2,988 per year or £372 per month. This gets you Inventor, Fusion 360, Inventor CAM, Inventor Nastran, Inventor Nesting, 3ds max, Navisworks, Recap Pro (for reality capture/reverse engineering) and, of course, AutoCAD.

In other words, this collection represents some serious value for money. On its own, Inventor is already a functionally rich product. When you combine it with industry-leading simulation, CNC machine programming and more, it becomes something very empowering.

Manufacturing & simulation: New tools in PD&M collection

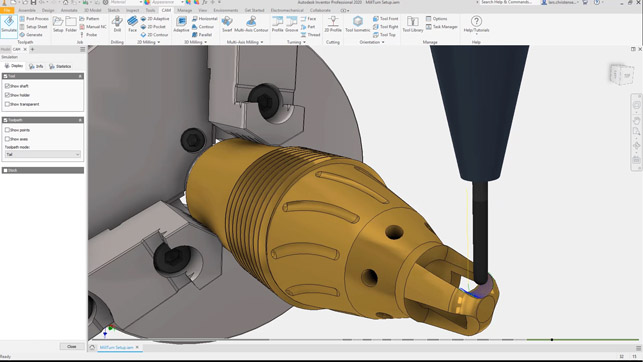

In recent years, Autodesk’s product range for manufacturing has grown from pretty much zero to a rich set of tools and technologies that covers everything from mould design and sheet metal through to 5-axis machining. So it was inevitable that some of these capabilities would make their way into Inventor.

In general, these types of tools are to be found in Autodesk’s Product Design & Manufacturing Collection. (In case you missed it, ‘collections’ is the term used by Autodesk for bundles of industry-focused solutions. There’s also an Architecture, Engineering & Construction Collection and a Media & Entertainment Collection.)

In its 2020 update, Product Design & Manufacturing Collection gains manufacturing technology in two key areas. First, there’s been a rebranding of the Inventor HSM product as Inventor CAM (not to be confused with the Inventorintegrated product from SolidCAM). This brings a range of CAM focused capabilities from basic 2.5-axis, through 3-axis and into 5-axis simultaneous machining.

Second, the Autodesk Inventor 2020 release sees the first time that Inventor Nesting has been made available as part of a collection.

Based on technology acquired from Magestic Systems in 2014, this is a pretty rich set of tools that allow you to quickly extract sheet metal forms from assemblies, carry out all of the true shape nesting you need, and perform sheet optimisation and scrap reduction tasks.

Of course, with Inventor CAM, there are also laser cutting capabilities or you can pass the data out of the system via DXF and so on.

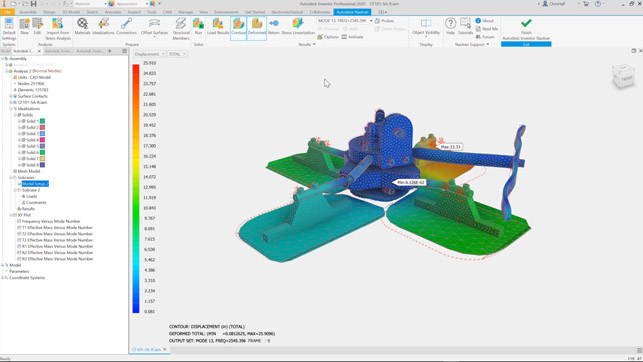

A final addition to the Product Design & Manufacturing Collection is the addition of Inventor Nastran.

Again, as the result of an acquisition, Autodesk Inventor 2020 has its own flavour of the Nastran simulation solver (as do Hexagon and Siemens PLM).

Inventor Nastran, meanwhile, sees that world-renowned simulation engine available as an integrated part of Inventor.

Of course, Inventor has had some stress-analysis technology for a while, but this is a whole new ball game, which includes linear static and thermal analysis, as well as some tools to help repurpose and idealise Inventor data for simulation.

| Product | Inventor 2020 |

|---|---|

| Company name | Autodesk |

| Price | on application |

Pingback: Autodesk Inventor vs Fusion 360 - Full Comparison & Table