While our review (Fusion 360 – Q4 2016) brings us up to date with what’s changed and been added in Fusion 360 over the last year, there is an on-going development road map which, for once, the software company is making public.

Fig.1 Bowser access to the full set of Fusion 360 capabilities is coming

Additionally, a good view into the near-term future of the product was shown off at the company’s recent Autodesk University event in Las Vegas. So here’s a summary of the key points shown and where things are heading.

Branch & merge

This has been floated as a forthcoming feature for Fusion 360 for a good couple of years now and it looks like 2017 will finally see it released into the product.

Branch and merge is a method of managing multiple design iterations in a single stream of managed versions and revisions.

It allows you to fork a part or product’s development, to explore options or ideas, then to bring those different iterations together into the final or on-going form.

Browser access

Last year, Autodesk quietly announced Project Leopard, which was the initial showing of its move to put Fusion 360 in the browser and its answer to the whole “Full cloud or not” question/debate/argument. While it hasn’t seen much discussion, the intent is clear.

The local install/stream of the Fusion 360 client will continue, but users will also be able to load up their browser, log-into Fusion 360 and create and edit models, without having to use the fuller install as they would currently.

Of course, that browser client will differ slightly in terms of looks and feel (we’d imagine), the capabilities will be much the same and you’ll be able to use it on a much wider number of platforms – including the iPad or even smartphones, if squinting at small rectangles is your bag.

Fig. 2 Sheet metal and PCB integration/interoperability will greatly benefit multi-disciplinary teams

Sheet metal

From the brief demo we saw, Fusion 360’s sheet metal tools are nearly ready. The workfl ow looks as you would expect, with a little bit of that Fusion magic added in.

As with all sheet metal design tools, the concept is that you’re always working with a uniform thickness sheet material, adding fl anges, bends and other features as you work up your model.

What makes sheet metal interesting in the context of fusion is that the process is always tied to building forms that take reference from other parts of a products’ structure — whether that’s building around PCB boards, within injection moulded components or encasing more mechanical or electronic/electrical items in a form that can be fabricated.

Here, Fusion’s ability to mix all of these up, using direct modelling techniques to finalise the form, makes a lot of sense.

Electronics, PCBS & Eagle

If you weren’t aware, Autodesk has been on something of a spending spree when it comes to electronics design.

The company has acquired a number of outfits that are feeding technology and capability into Fusion 360. Perhaps the biggest news is that Autodesk now owns the Eagle PCB design tools. So you can expect, if not a direct integration of the design tools, certainly a better level of associativity between the mechanical design tools in Fusion 360 and the PCB design and layout tools inside Eagle.

Alongisde this, Autodesk also acquired ECAD.io in 2015, from the team that developed SolidWorks’ CircuitWorks add-on, so there will also be greater interoperability with other PCB design tools (primarily using the IDF format as the conduit).

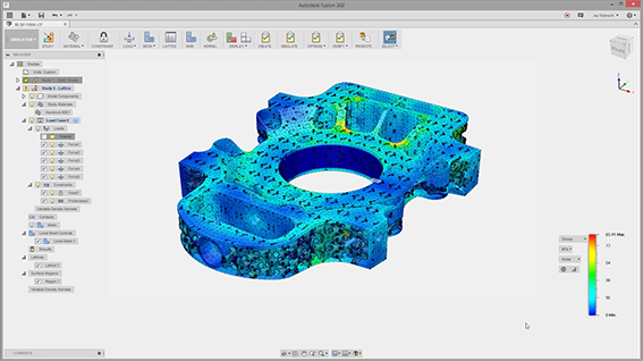

Fig. 3 By integrating technology from both Within Labs and NetFabb’s more advanced tools, Fusion 360 will see introduction of lattice design tools

Fig. 4 Autodesk acquired deposition simulation specialists, Pan Technologies

Lattice design & additive

Additive manufacturing is something that Autodesk is bullish on. Over the next year or so we’ll start to see greater integration of tools and technologies that it has acquired making their way into Fusion 360.

Tech and knowledge from both within the NetFabb acquisitions will start to creep into Fusion (NetFabb are behind many of the medical case studies you’ll have seen). This will focus on providing tools that allow you to take solid geometry and ‘lightweight’ it using lattice structures.

What’s interesting here is that there’s huge potential for saving weight, but also adding in addition functionality to parts, whether that’s gradient mechanical properties or assisting with implant acceptance in the medical field.

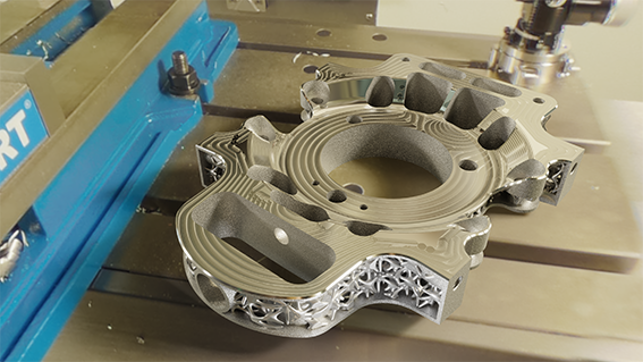

Alongside the lattice design work, Autodesk also acquired Pan Technologies, a start-up that has focussed on the simulation of powder bed and metal deposition process.

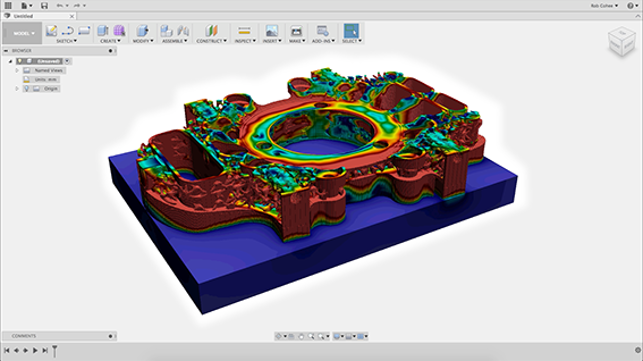

At AU, Autodesk showed off its workflow, from lattice design (Figure 2), simulation (Figure 3) as well as how that data can then be fed into the machining process for post-additive build machining operations, including the ability to accurately visualise how that final part will appear, complete with the tool markings from machining as well as the additive portions (Figure 4).

Fig. 5 Mixing additive and subtractive in a single visualisation

Keeping up to date

Autodesk is pretty transparent with its development plans. If you want a look at the roadmap it’s updated at the following address: fusion360.autodesk.com