The headline update for Geomagic Studio 11 is the introduction of a set of tools designed to bridge the often wide chasm between physical data capture and digital design. Geomagic has been working towards this goal for the last few releases, most notably with the introduction of the Fashion module.

This offers the ability to extract design intent and, with a wide variety of surface fitting tools, reconstruct clean, accurate surfaces which can be read into your workhorse CAD system. This release not only extends these tools further by consolidating commands and workflow and adding new tools, but it also adds another level of intelligence to the process.

The high-level concept is that, by using this set of tools, the physical form of a component can be captured and rebuilt not only as a set of CAD-readable surfaces, but with a reconstructed CAD-native feature tree. This allows users to make much more use of the geometry than would be possible with dumb surfaces. It also means design intent can be added.

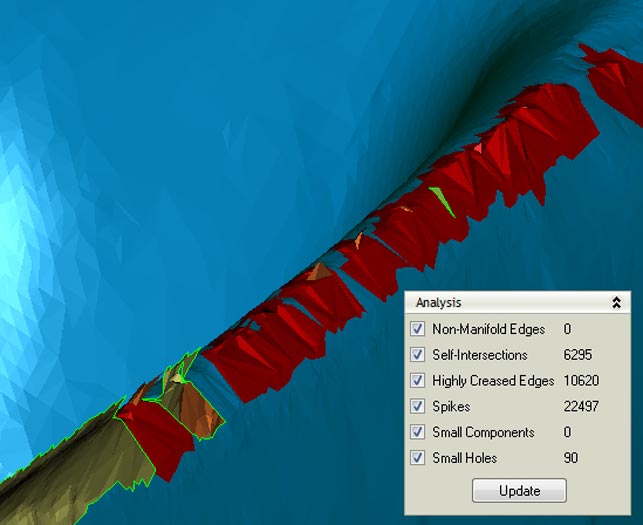

An imported polymesh that has all manner of errors within it. The Mesh Doctor runs a series of checks for common problem areas and reports back the results. The system can then automatically fix them or the user can dive in and work on them manually

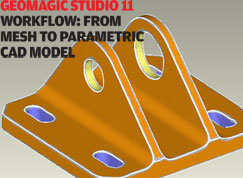

In its first release, Parametric Exchange interoperates with 3 and 4, Inventor (2009 and 2010) and SolidWorks (2008 and 2009). The workflow is something a little like this and can be followed visually at the bottom of the page: The user begins by working on scanned data within Geomagic. For those unfamiliar with the system, it presents a wealth of tools for working with point cloud data. Separate scans can be registered, data can be cleaned, a watertight polygon mesh can be built and unwanted features removed. The user then dives into the system and inspects the poly-mesh to find fillet radii and all manner of surface types (such as planar surfaces, cylinders, etc).

A guide to the basic Geomagic 11 workflow

The next stage is to start to define each of those to the level of detail required. Initially, open surfaces are created. Fashion now includes all manner of tools for extracting curves and sketches from the point cloud, and editing as required to create “good” curves. The end result is a mixture of untrimmed and trimmed surfaces (and boundary curves) that are ready to be transferred to the CAD system. At any point in the process users can inspect how much that surface-based definition of the part deviates from the scanned data.

In the SolidWorks example shown in Figure 4 when transferred to a CAD system, the API is used to reconstruct the features, surfaces and curves in a logical history tree. It’s worth noting that each entity is contained within the feature browser to the left of the screen – and this works much the same regardless of whether Inventor, SolidWorks or Pro/Engineer is used. The next stage is to use that data to add the final trimming, cuts and splits to create the final watertight model.

Mesh Doctor

Alongside Parametric Exchange, the other big news for the Studio 11 release is the introduction of the Mesh Doctor. When dealing with reverse engineered data, whether coming from a processed point cloud, an imported polymesh or anything else, errors within that data are very common indeed.

The nature of any reverse engineering process – whether using traditional CMM style processes or the increasingly common non-contact scanning devices – means that holes, gaps or other errata appear. This is the main reason that systems such pas Studio exist in the first place.

What Mesh Doctor represents is a persistent set of checks that can be carried out on polygon meshes to ensure users have the best quality data to work with. Mesh Doctor is initially used when opening the dataset and runs a series of checks that look for errors, such as non-manifold or highly creased edges, self intersections, and spikes, or small components and holes that may typically appear.

The system analyses these and presents the user with a list of errors that can be selected, inspected (using the 3D view to zoom into problem areas automatically) and dealt with accordingly. Common problems can be rectified automatically and Studio handles that following a click of a button. In cases where the automated tools can’t be used, Studio enables users to dive in and work with the geometry manually, replacing geometry, filling holes and fixing errors.

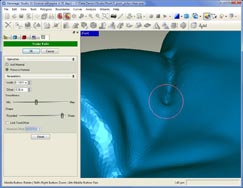

The Sculpt Knife tool provides much greater control over manual smoothing where the user paints in smoothing operations interactively on the geometry

Other updates

In terms of the less ‘headline grabbing’ updates there are new tools related to working with new geometry, rather than data generated by scanning hardware. The first, the Mesh Radius Analysis tool, allows the use of curvature analysis to find the radii of either all edges within a part (perhaps a moulding which is typically more filleted than a metallic component) or a specific selected area.

Mesh Radius Analysis gives a reading for each radius found which can then be used when defining proper fillets downstream in a CAD system. This tool is incredibly useful to restore design intent with used or retired components where time has taken its toll, and provides a decent baseline set of data to work with further.

Hole filling is something that every reverse engineering user will be familiar with – mostly because in many cases it can mean major headaches, particularly when working with complex, sculpted surfaces. Studio now includes a Tangent Filling option that fills holes while maintaining the tangency of the surrounding geometry. This is intended as an alternative to the Curvature Filling option which, although incredibly powerful, can sometimes give erratic results, particularly with complex forms.

An interesting update is the Relax Polygon option. Previous versions of the software smoothed out errors with ease, but this could have a rather undesirable effect on edges. The new release provides a Curvature Priority option that ignores areas where high degrees of curvature are found (namely, edges) and these will be locked out from smoothing operations. The tool provides a visualisation of what’s locked and what’s not.

Also on the subject of smoothing, the new Sculpt Knife tool provides much greater control over manual smoothing (where the user paints in smoothing operations interactively on the geometry). This provides control over the width (or to use the painting analogy further, brush sizes) and the amount of offset allowed (or the distance polygon vertices can move to achieve that smoothness away from the original geometry).

Finally, there’s been some cross-pollination from the Fashion module into Studio, with the ability to trim polygons with a curve. This allows the use of a curve to define the boundary of a sub-set of a model, either sketched in manually or using curvature change to drive the creation of the sketch.

Conclusion

By taking a broad look at the process of reverse engineering or the capture of digital data from physical parts, there are two forces at work. There is currently an explosion in the hardware available to capture the raw data. Some are highly complex and accurate, but costly solutions, while others make use of consumer grade electronics to achieve a lower price point, but this often comes at the expense of accuracy. While there’s a boom in reverse engineering hardware, perhaps the most critical part of the process is doing something with that raw data.

It’s in this field that Geomagic has built up its expertise over the last decade, providing tools that allow users to work with raw source data and create usable geometry. With the Studio 11 release, this advances greatly, particularly with the introduction of Parametric Exchange, which allows users to take physical data and create solid, accurate, clean and above all, intelligent CAD models – and by doing so, adding design intent and editability back into the process.

Alongside Parametric Exchange, the other major updates for this release continue much of the good work Geomagic has been putting into the products over the last few years. While all of the tools have been there in some shape or form for a while, the last few releases have seen much consolidation of commands. A good example is the Mesh Doctor. While this doesn’t represent new functionality, it takes existing tools, brings them into a single, persistent dialog and allow users to work on geometry, fixing errors and re-running checks, all from one place. This can only serve to make these processes, which are often time consuming, much more efficient. And you can’t ask for much more than that in my book.

| Product | Studio 11 |

|---|---|

| Company name | Geomagic |

| Price | on application |