Stratasys (Dimension Printing’s parent company) made its mark in the rapid prototyping world when it introduced the Fused Deposition Modelling (FDM) process that’s is now at the heart of all of its products.

Like most rapid prototyping systems, FDM builds 3D models sequentially in thin slices. But while other systems use powders, resins, lasers and other optics, FDM uses a filament of extruded material to build its 3D model. Where SLA (Stereolithography) traces the outline of a part layer then fills it in, FDM deposits near molten material from a nozzle, tracing the exterior boundary of each layer then zig-zagging within that to add the material.

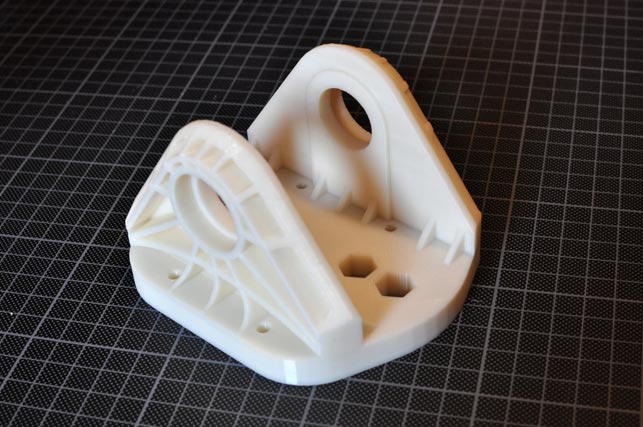

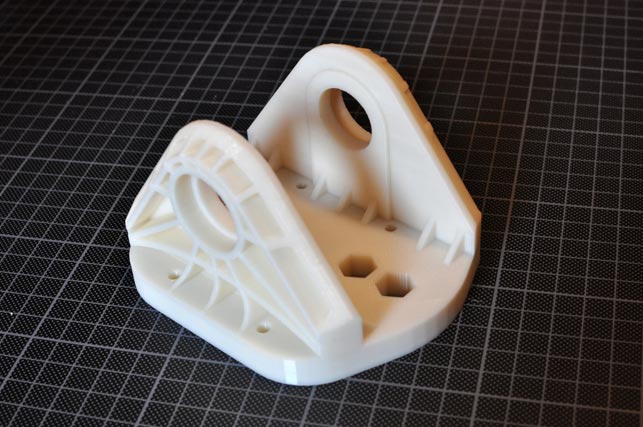

FDM models are renowned for their toughness and accuracy making them suitable for physical testing

In most FDM machines the system also deposits a support material to assist with maintaining form within the model during the building process and to allow users to build complex parts in the required orientation. This support material is then removed (it’s water soluble) and hey presto, there’s a 3D model, realised as a physical 3D part.

The benefit that FDM has traditionally held over its competitors is the superior structural integrity of the parts. By using near molten material (typically ABS but others are available in the higher-end systems), the technology gives users a very good approximation of product-intent material. Parts are more resilient, suitable for form, fit and function testing and generally stand up well to the rigours of life as a prototype part. So, there’s the background, now let’s looks at the specifics of the uPrint machine, which Dimension is touting as a personal 3D printer.

Personal service

The uPrint is a very small form factor machine and it sits easily on an office desk. I would hazard a guess that this is about as small as these things are going to get considering it sports a very usable 203 x 152 x 152 mm build envelope. Installation is very similar to that of a traditional printer. Everything is clearly labelled and there’s even a quick reference guide.

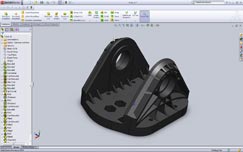

The part in SolidWorks – an STL file is exported to the required resolution. Higher resolution will mean much less faceting in the final model

The machine comes into two core parts: the printer itself and the material bay. The material bay sits underneath the printer and can be doubled up to offer longer periods of unattended model building. Once it’s assembled, you connect the machine via Ethernet and get the software up and running.

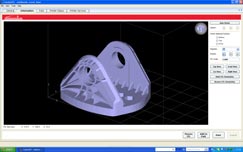

The system comes with Catalyst EX software which offers all you need for model preparation, from machine admin and control, through STL data import, orientation and scaling tools to prepare each build job.

Inside each material bay the ABS and support material are held in reels of filament, which are fed directly into the nozzle. These are 0.254 mm in diameter and this dimension not only defines the layer thickness during the build process, but also has an effect on the resolution. While FDM models are known for being dimensionally accurate, when working with intricate detail (close to the 0.254mm dimensional limit), it is possible to run into problems. That said, judicious choices made when orienting the part, can certainly help achieve the desired level of detail.

The part in Dimension’s CatalystEX application, which allows users to define a range of build parameters

At present, the uPrint only has one material option – Dimension’s ABSplus – and it’s only available in ivory (or off white). While the material is actual ABS, it’s important to realise that the exact same production intent characteristics of injection-moulded parts will not be achieved because of the inherent weakness of the layer-based build process. Still, compared to some 3D printing methods, these are exceptionally hard-wearing models and you can do most things to them including, milling, drilling, painting and even electro-plating.

In terms of the actual build process, models are built up layer by layer directly on to a ‘disposable’ model base. While Dimension discourages re-use of these bases, it is generally perfectly acceptable.

Build speed is not exactly fast, but comparative to other 3D printing systems. For example, the test model we supplied (see Figure 1) has a biggest dimension of 100mm and took 13 hours to build.

At the end of the build process, little post processing is required as the support material is water soluble, but an optional clean station is also available that automates support removal.

Parts are more resilient, suitable for form, fit and function testing and generally stand up well to the rigours of life as a prototype part

Cost of ownership

The uPrint represents a step change for Dimension Printing. The company has seen huge success with its range of BST, SST and Elite 3D printers and has shifted a huge amount of units. The competition between Dimension Printing and its arch-rivals Z Corporation and Objet, has helped drive down the cost of 3D printing technology over the last few years. But the introduction of the uPrint takes this a step further.

The start price for the uPrint is £12,500. This gets you the machine, one material bay (plus a carrier for both build and support material), the Catalyst EX software, some build and support material to get started and a year long maintenance contract. If you want to add the additional material bay, that costs £1,275 and material carriers for both build and support materials are £250 each. The optional clean station costs £2,250.

While the capital costs of the system are critical, you also need to bear in mind the on-going costs of owning and maintaining one of these machines. A year’s maintenance is included with the device, with additional years being £1,600 per annum, and I’d certainly recommend this. Even though the technology is comparatively simple compared to other 3D printers, the last thing you need is a spool jam or blocked nozzle when you have a project deadline looming.

Available in red, green and white the uPrint is much smaller than many 3D printers and set-up is incredibly simple, taking inspiration from 2D printers

In terms of consumables, the ABS plus material costs £690 for five spools. The support material is the same price and while you won’t typically use as much as you will build material, it can vary depending on the form of your parts. Other than that, the model bases cost £115 for 24 of them.

In terms of raw material costs, the part you see in Figure 1, which has a biggest dimension of over 100mm, cost £27.51 for the build material and £12.33 for the support, so all told around £40.

Just out of curiosity, I ran the same STL file through a number of online service providers and the lowest quote I got was over £300. Now, while I’m no accounting expert and understand that capital costs need to amortised, if you’re a heavy user of rapid prototyping and maybe already invest heavily in outsourced FDM model builds, being able to recoup the cost of the machine in around 50 builds or less seems very good value.

Conclusion

When looking at overall running costs the uPrint presents solid value for money. It’s also an extremely well-engineered product and the models, made in durable production intent ABS, are impressive.

Bringing 3D printing in house is a big leap for some, but it can bring huge benefits to the product development process. Because the design team has the machine to hand it will use it to its fullest potential, rather than erring on the side of caution when outsourcing. After all, if you purchase a tool, you need to use it more to get more value from it. No hassle of getting purchases signed off, no waiting for the FedEx man to show up with a package of broken bits, just the ability to fabricate your prototype models and get on with the job.

If you want another perspective on the uPrint, I’d suggest you download Lou Gallo’s SolidWorks HEaRD podcast (solidworksheard.com). He has a nice audio-based introduction to the uPrint, from unboxing to test builds.

uprintTech Specs

Machine dimensions (W x D x H) 635 x 660 x 787mm

Machine weight: 76kg (with single material bay)

Build envelope: 203 x 152 x 152mm

Layer thickness: 0.254 mm

Build method: Fused Deposition Modelling (FDM)

Model material: ABSplus (single ivory colour)

Network connectivity: Ethernet TCP/IP 10/100 base T)

Support removal: Water soluble (optional cleaning station)

| Product | uPrint 3D Printer |

|---|---|

| Company name | Dimension Printing |

| Price | From £12,500 |