Here’s a strange one. The world surrounding rapid prototyping often focusses on the additive, layer-based processes, SLA, FDM, SLS etc etc. That’s fine. But if there’s one thing these systems are not. its rapid. At an inch an hour, Z corp is probably the fastest.

The thing that often gets missed in the many publications and trade shows surrounding that tag, is that there are much quicker ways to create prototypes and the strange thing is, that they typically are much more cost effective and less complex than their additive counterparts. The perfect example is Roland and its range of Modela products. These are effectively small form factor CNC machines, many capable of cutting some tough materials, from the usual chemical wood, resins and model-board, through all manner of plastics and such and into metals, particularly aluminium and copper (which is super handy for electrode machining). What the smaller machines (the MDX-15 and MDX-20) lack in the ability to cut tougher materials, they do make up for with digitising tools, using an integrated probe. The Larger machines (the MDX-540 range) are more benchtop, rather than desktop, but give you much bigger working envelopes, greater cutting speed and (with some accessories for tool changing and auto-rotating billets) unattended operation.

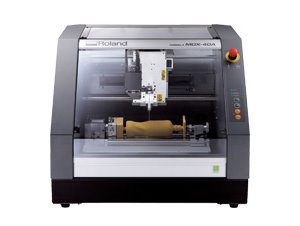

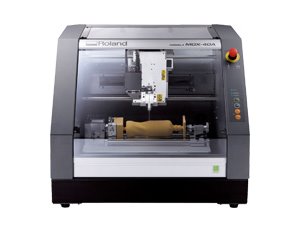

Roland has just launched a new machine which bridges the gap between the end of their range, the MDX-40A – an iteration of the MDX-40 launched a little while ago. This is based on a much more rigid chassis that the desktop machines, provides you with automation options and gives you the ability to cut tougher materials – but in a much smaller form factor.

It’s got a build envelope of 305 (X) x 305 (Y) mm 123 mm (Z). If you have the new optional rotary axis, it’ll support materials up to 270mm long by 120mm in diameter (10.63” long by 4.72” in diameter) – four times the previous model – and its big enough to mill a 500ml bottle. I’ve met a great number of people in the structural packaging space and they swear by these things, as they can do amazing things with acrylic (Tin Horse spring to mind).