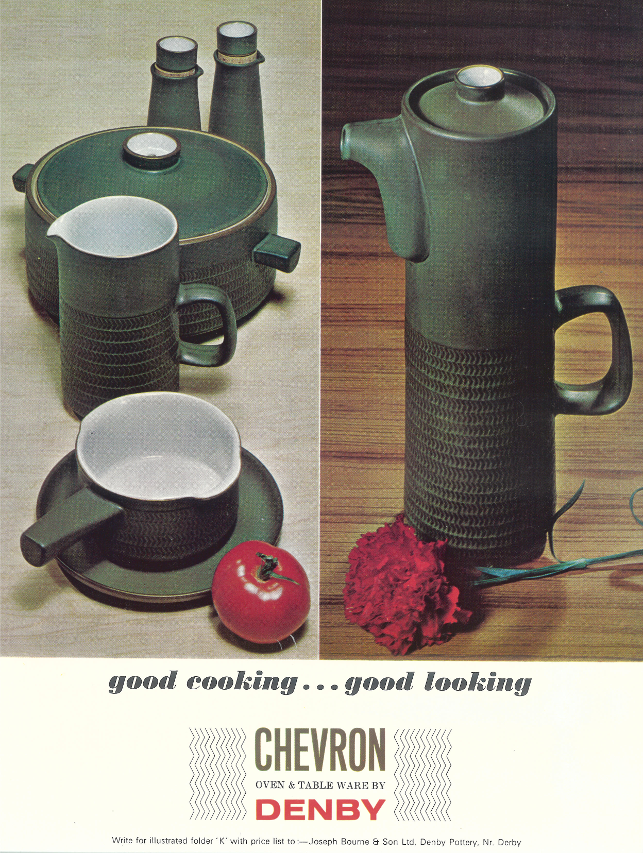

The ‘Natural Canvas’ range was inspired by Denby’s 1962 Chevron range

In its journey from clay to pot each item of Denby Pottery gets passed through over 20 pairs of hands. The raw material, which comes from the same seam of clay the factory was founded on 200 years ago, is piled into an 18 metre high ‘Denby mountain’ that stands just behind the factory. From here the clay is moulded and shaped, fired in the kiln, glazed, fired in another kiln, hand finished, then possibly back in the kiln again if a pattern has been applied, and then inspected.

It is a process that takes two to three weeks and, on average, 100,000 stoneware pieces emerge from the factory each week before being boxed up and distributed to 40 countries around the world.

New for 2017 is the Denby Studio Craft range, which comes in four wood-inspired glazes and features ridged items, such as the bowl

Located within the factory is the design studio where Richard Eaton, Denby’s design director, heads up a small design team. Having been at the company for over 30 years, he knows a thing or two about designing pottery and for him the defining aspect of the process is its experimental nature.

“We are often described as the biggest studio pottery in the UK because at our heart we make beautiful stoneware but in an industrial way,” he says.

“We design as though we are only going to make two or three pieces rather than ten or twenty thousand. So, for us, the whole design process is experimental and we never have a really tight brief that says we have to have a certain size of pot at a certain colour.”

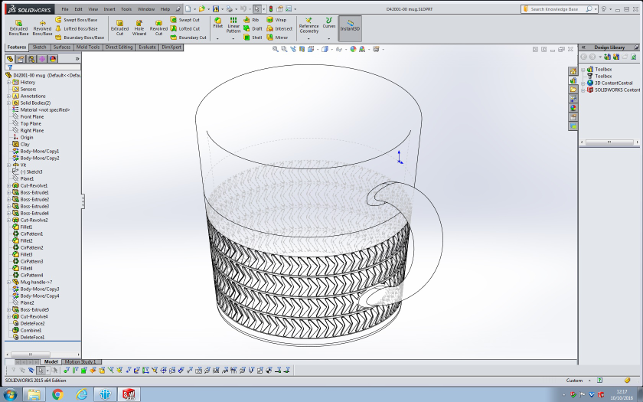

The ridged effect on the outside of the mug in the Denby Studio Craft range was created in SolidWorks and then numerous prototypes produced using the ZPrinter 650

Taking shape

The design team is essentially split into two disciplines – shape development and then colour and pattern.

In terms of the former, not that long ago, the company’s designers would utilise craft skills for prototype development. For instance, hand throwing – that quintessential image of making pottery that involves throwing a ball of clay onto a revolving wheel and then forming the pot into the required shape by hand. The handles, for instance, would then be cast by filling a Plaster of Paris mould with slip (clay and water).

“When I first started here in 1998 I barely saw my colleague Gary Hawley, who was working on shape development, because he was hand modelling and carving handles out of plaster. In quite a short space of time technology has changed working practices,” says Nicola Wilson, senior designer at Denby Pottery who is largely responsible for colour and pattern.

First it was the investment in CAD, which allowed for the accurate 3D modelling of shapes. Then, in November 2006, Denby Pottery was one of the first manufacturers in the ceramic industry to employ a rapid prototyping machine (or 3D printer in today’s lingo) with the aim of cutting down the time it took to currently create prototypes (sometimes as long as four weeks) and, in turn, the time it took to bring products to market.

The company opted for Z Corp’s Spectrum Z310 fullcolour 3D printer (now owned by 3D Systems). Although the original intention was to use it on an occasional basis, within a short space of time the machine was cranking out prototypes all week for internal review by the design team but also for meetings with management and for focus group testing.

Casting a teapot. Moulds such as this are created by Denby’s designers from 3D printed models

“We found that it was a good machine for us because firstly, at the time, it was fairly cheap to run, and secondly, because it was so quick and easy to use, we could build ten different handles instead of just one to see what they looked like in terms of form and feel. In a sense, we were using it to sketch in 3D because neither the material nor the build time was precious,” explains Eaton.

In fact, they wore out that first machine and were classed by its manufacturer as a heavy user of the technology. “I remember the guy who invented the machine coming to visit. He was in the UK and had been to see an F1 racing team, which obviously uses the machine quite differently from ourselves being in the engineering industry, and in the afternoon he popped in here where we showed him how we use it to make mugs and plates,” laughs Eaton.

“But I think they were so happy to see somebody using it to the extent and for the application we were.”

Now on their third machine – the ZPrinter 650 – with the other two burnt out and in the cupboard, Denby’s design team also discovered an unanticipated benefit of 3D printing – that of using it to create moulds from the 3D printed models. The CAD data is used to make silicon case and plaster block moulds whereas previously these would have been carved by hand. This further saves time as well as increasing accuracy of those moulds.

As Eaton says, projects now take 18 months to two years whereas they could have previously taken up to four years.

However, to cut time even further the design team are currently looking at ways to 3D print the pots directly in dry clay so that they are ready for glazing immediately.

“So instead of going from a white plaster model back through all the engineering process that we do, in essence, you can go straight to an idea. It’s still in it’s infancy, but the opportunity to print clay in the same way as metal or plastic is printed would save quite some time building prototypes,” says Gary Hawley, senior designer.

The Denby Pottery design team with Richard Eaton, design director, seated centre

Right tool for the job

But despite this extensive use of 3D printing, Eaton makes it clear that they aren’t slaves to the technology. Rather they utilise the prototyping method best suited to a particular project.

For instance, in the latest ‘Denby Studio Craft’ range, the new ridged mug and bowl were prototyped in two very different ways.

The design team, who like to keep abreast of various lifestyle, food and home interior trends, had noticed that consumers were favouring a natural aesthetic in their homes and so aimed to give this new range a relaxed and earthy feel both in terms of shape and colour. The ridged feature on the outside of the mug and on the inside of the bowl (which is a wide bowl available in two sizes) would lend to this aesthetic.

“The bowls came from a hand thrown piece and hadn’t even seen a CAD machine from sketches – we went straight to the potter’s wheel to create that prototype,” explains Eaton.

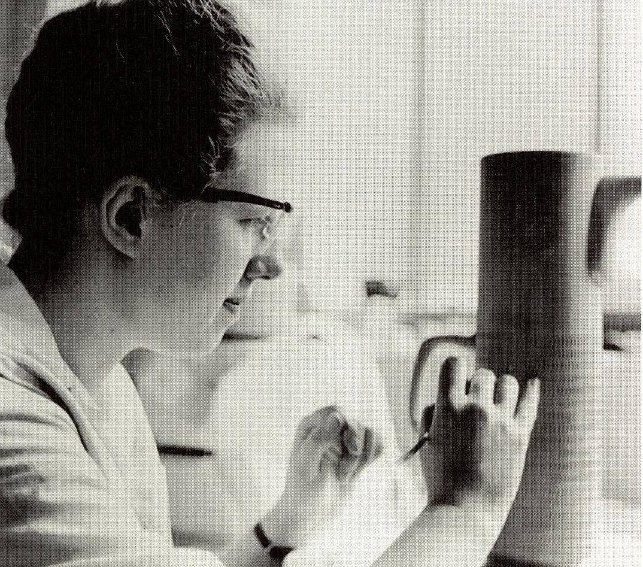

Gill Pemberton designed Chevron in 1962, which she is hand-etching here

“Whereas, the mug came completely from CAD and 3D printing because we knew it had to be engineered for the ridges that come out of a mould. But despite these different processes for NPD [new product development] they still look part of the same range and you don’t feel there is any disconnect between the two.”

Although only these two items were created from scratch, the other universal pieces used in ‘Denby Studio Craft’ will feel completely different with a new glaze, which comes in four wood-inspired tones.

“The initial inspiration behind these was a textured wooden spoon as I loved the warmth of the tones and the texture of the wood grain,” explains Wilson.

This Scandinavian-esque range was very popular and reacting to modern trends Denby’s designers decided to resurrect it using today’s technology

“The unique thing to Denby Pottery is that we are working with very reactive glazes unlike a lot of the industry that have a clear glaze on white which they then put a pattern on. This involves the designers working closely with the glaze team, who have a wealth of knowledge about the raw materials needed to create the glaze ‘recipe’ and how to combine them to achieve Denby’s wide variety of colours and finishes” adds Wilson.

Denby Pottery – Blue sky thinking

Although the design team have launch windows throughout the year, Eaton promotes “blue sky thinking” amongst the designers encouraging them to have their own pet projects bubbling away in the background.

“It’s that blue sky thinking which I think helps create a lot of the newness that we do otherwise we’d end up redesigning ourselves all the time. So we are all looking for the next big ‘wow’ and then we go off on a different tangent. It might not be on the agenda but if we think it’s really good, we’ll go do it,” says Eaton.

One such idea came from Hawley who felt inspired to resurrect a chevron design that artist Gill Pemberton had created back in 1962. This Scandinavian-esque design was very popular at the time and Hawley thought that, with a bit of an update, it could be just as popular today.

Whereas each item would have been created by hand, today the chevron pattern was designed in SolidWorks

Although he wanted to copy the rouletted feature that runs along the bottom of the original stoneware he didn’t want to use the same process used at the time, which involved painstakingly creating the indentations by hand with a small tool that was pushed into a clay pot as it was being spun round on the potter’s wheel. Instead he used CAD to emulate what was done at that time by hand.

The team knew that he was onto something and so they decided to launch a new ‘Natural Canvas’ range with key items – namely the mugs, cups, jugs, teapot, sugar bowl and cafetiere – carrying this new chevron pattern.

While Hawley was refining the Chevron pattern in SolidWorks and then through the use of 3D printing, the glaze team were working on a neutral glaze that would give the range a naturally white yet contemporary feel.

“In the first trials that Nicola glazed, the dark clay body colour of the chevrons broke through. So I ended up going back into SolidWorks to make the pattern 0.3mm instead to give it the right depth so that the glaze would sit over the top,” explains Hawley.

The process of making the resulting Natural Canvas range involved many rounds of 3D printing

Also, the chevron pattern resulted in a different mould process than normal. “We had to run silicone cases over those plaster models so that it was flexible enough to allow for the depth of the texture, which was a bit of a challenge for our production team but it is good to keep them on their toes,” laughs Hawley.

Although he jests, the production team are the crux of Denby Pottery and it’s those 20 pairs of skilled hands that each item passes through that results in a product that feels handcrafted yet is of a very high quality, with each one ever so slightly yet pleasingly different from the next.