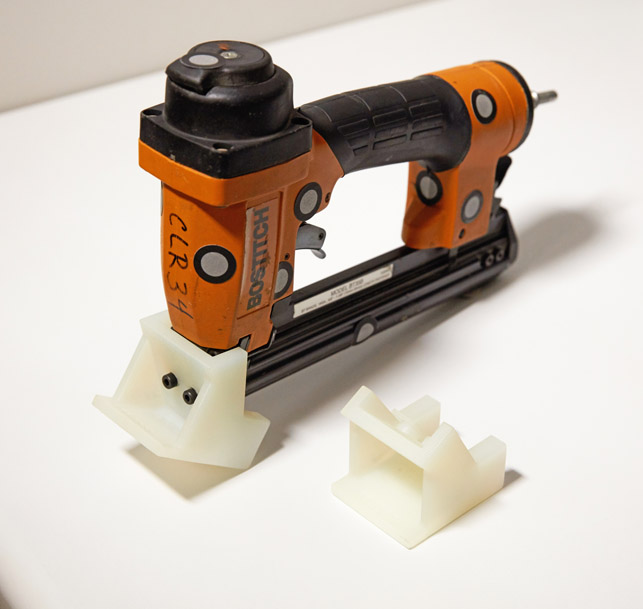

Furniture pin tack gun guide, 3D-printed in Durable Resin

Atour around Ashley Furniture’s Arcadia, Wisconsin-based manufacturing facilities soon reveals the recipe for the company’s success. As with most modern manufacturers today, you’ll find a variety of new technologies at work there, and 3D printing is a big part of the picture. It has slowly trickled onto the factory floor, and gradually transformed a range of manufacturing processes, from fabrication to assembly.

The incremental adoption of 3D printing technology at Ashley Furniture has been quite deliberate. It is a clear example of the company’s commitment to lean manufacturing processes and a kaizen approach.

This is characterised by employee-driven incremental changes, which save significant time and costs in getting products to market, and empower staff to be more productive and focus on more creative work in their day-to-day jobs.

“We started out just making one simple sample, because we could make that sample in a matter of a few hours versus having to potentially source from an international vendor that would take weeks,” says Vaughn Pieters, senior director of casegood operations at Ashley Furniture.

“We were able to use 3D printing technology to compress some of those timelines and make better more educated decisions with our design staff,” he continues.

“Now, we’ve continued to grow that with how we use 3D printing technology, to make components that help us run our day-to-day business on the manufacturing floor.”

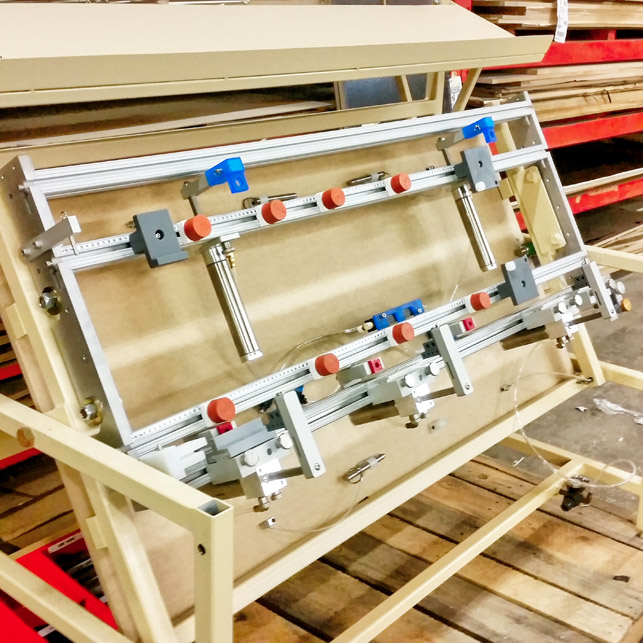

A universal assembly fixture system uses 3D-printed parts to simplify adjustments between product changeovers, completely eliminating the need to spend machine shop resources to build each new fixture from scratch

3D printing technology – adapt and change

In addition to time and cost savings from outsourcing parts, 3D printing technology has transformed some more traditional processes on the floor. For example, the company has developed a universal system for an assembly fixture.

Now, when introducing a new SKU [stock taking unit], production engineers only need to print new parts to adapt the system, and assembly workers follow simple instructional guides for each changeover. The system has significantly reduced set-up time in the assembly area, as well as the storage footprint of the original large fixture pieces, which could weigh up to 200 pounds.

“We’ve literally replaced fixtures that are three feet by six feet with a simple bin system; it’s a two-minute setup time,” says Brian Konkel, a production and design engineer. “It frees up jig builders from repetitive tasks to work on more pressing issues, from busy work to looking at more challenging items.” Pieters adds: “Things like 3D printing and automation are making the job easier for the employee so that it’s not so heavy and not so industrial.”

Key to taking full advantage of new technologies is ensuring they will grow with your ideas. Ashley Furniture takes full advantage of Formlabs’ Engineering Resins, for example, and is constantly experimenting with new resins.

This flexibility in finding solutions that can replace machined parts, and being able to stand up to the rigours of cycling through shifts on the floor, is part of what helps Ashley Furniture scale its use of 3D printing technology, with no signs of stopping.

Furniture fabrication and assembly boosted through onsite 3D printing

Default