At bolting solutions specialist Nord-Lock Group, the Boltight and Superbolt businesses are using augmented reality, powered by PTC, to showcase their products at customer sites and exhibitions

An offshore drilling platform has hundreds of critical bolts and often requires miles of pipeline to be laid underwater and then across land to transport oil and gas to a refinery.

All along these large diameter pipelines are flanges that feature large numbers of hefty bolts, which, for obvious reasons, need to be securely tightened.

“When those bolts are tightened, you have to ensure that they are not going to come loose through wear and tear,” says Sandy Andringa, marketing manager at Boltight.

Boltight and Superbolt are part of the Nord-Lock Group, specialising in both mechanical and hydraulic tensioning products to help secure bolts in environments where safety and accuracy is paramount.

“Essentially, how hydraulics work is tensioners are attached to a bolt or stud, and high pressure hydraulics are applied through a hose to tighten by axially stretching the bolt.

This ensures that each bolt is tightened in the same way and at the same pre-load,” Andringa explains.

“Superbolt tensioners provide a mechanical advantage by dividing the load among multiple small jackbolts,” adds Jason Kozlowski, marketing manager at Superbolt. “These multi-jackbolt tensioners [MJTs] can stay tight securely and indefinitely after they are properly installed.

Even more impressive is that all sizes of MJTs – even enormous ones – can be safely installed or removed by a single worker, using ordinary hand tools.”

In-person demonstrations of how tensioners work can be a cumbersome endeavour, as they involve lugging heavy tools around to customer sites and exhibitions.

However, at a forthcoming oil & gas sector show in May, Nord-Lock Group will be demonstrating both Boltight and Superbolt products virtually through the use of augmented reality (AR) powered by PTC.

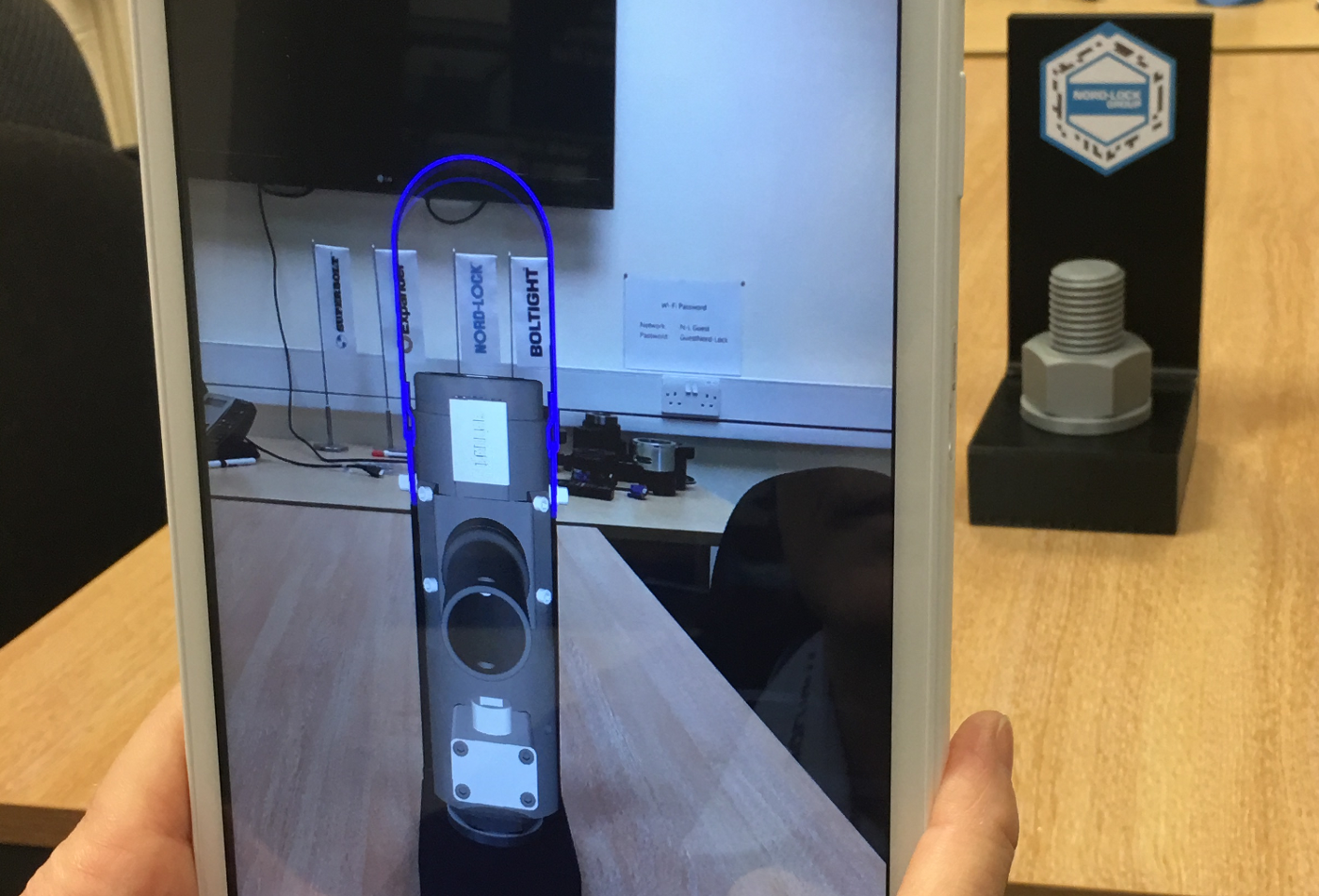

To view this experience, the user simply downloads the Vuforia View app from Google Play or Apple App Store onto their mobile device.

They then scan the code using this app and immediately it will bring up a 360-degree experience that they can view and walk around.

“For the first time on our stand, we’re going to have a virtual metre-high flange section, which will appear when you scan the mark on the ground.

Using the app, visitors can then walk around and view a demonstration of how four of Nord-Lock Group’s products are used to tighten and secure bolts onto that flange,” say Kozlowski.

Starting out in AR

The company’s interest in AR goes back to mid-2018, when a young Boltight engineer came to hear about PTC’s AR capabilities through PTC reseller, Concurrent.

When Andringa joined the company, the engineer demonstrated the AR and she straight away saw the potential, especially from a marketing perspective, as well as the ability to demonstrate the hydraulic tool range of products.

“My initial thoughts were that it would be brilliant for exhibitions, to demonstrate how a virtual tensioner fits onto and tightens a bolt.

Almost like an extension of our catalogue that, instead of having products static on a page, a user can scan the mark and the products would be brought to life through an AR experience,” says Andringa.

Buoyed by this possibility, Andringa met with the Concurrent team to discover what would be involved in designing such experiences.

“Having met with Concurrent, we realised it wouldn’t be too much of an investment to start things off, so we decided to kick-start a project to create an AR experience for our Typhoon hydraulic tensioning tool, which is predominantly used for wind turbine applications, at a forthcoming exhibition to see what could be achieved,” she explains.

Before actually designing the experience, Concurrent first held a workshop with Andringa and her team.

“We call this a discovery workshop, which we do with all our clients before designing an AR experience,” explains Atif Khan, technical consultant at Concurrent.

“Through this workshop, we build up a storyboard to help us fully understand who the end user viewing the AR experience will be, as this ensures that we create an impactful AR experience,” he continues.

“Tailoring the experience to the end user ensures that it’s something that they will keep referring back to. It will then start being used as a standard day-to-day piece of technology, and this is where AR becomes really powerful.”

Creating the AR experience

To create this initial AR experience of the Typhoon tensioner, Khan first had to import the Typhoon’s Creo CAD files into Creo Illustrate.

“In Creo Illustrate, we can create any illustrations and animations.

In the example of Boltight, this included an exploded view, showing all the different components in the tool and then an animation demonstrating the tool in use,” says Khan.

These files are then imported into Vuforia, PTC’s enterprise AR software.

It’s here that the layout and user interface is created, along with all the information the user needs to understand how the tool is used, including ‘click throughs’ or links to technical datasheets, YouTube videos and the enquiry page on Nord-Lock Group’s website, for example.

This first AR experience proved to be very successful, not only at the wind turbine exhibition for which it was created, but also for customer demonstrations, saving on travel and posting costs.

“We had a customer who wanted to see exactly how our tensioner would fit on their bolt.

We had to print a 3D model and ship it to them. But if we had already had AR using Vuforia View, we could have produced the exact specification of their tool from the CAD models in Creo, sent those across and they could have virtually placed that on that bolt,” says Andringa.

Boltight now has five AR experiences developed. In 2019, three further AR experiences were developed for Superbolt.

“With the latest Superbolt AR experience, we show the user how to tighten their mechanical tensioner.

So rather than just highlighting what the product is, AR allows us to take it to the next level, by guiding users through the exact, correct installation procedure,” explains Kozlowski.

Getting to grips with AR

While Concurrent developed the first couple of AR experiences, Andringa and Kozlowski went on a training course with the Concurrent team to learn how to use the software themselves, including creating animations in Creo Illustrate and then putting them into Vuforia Studio.

“Vuforia Studio is really user-friendly, as it’s a very drag-and-drop method of working.

Essentially, whatever widget, buttons, images or tables you want to show in the experience, you have a list of them and you can simply drag and drop them onto your working ‘canvas’, which is what you end up seeing on the mobile device,” says Khan.

“On top of that, it also eliminates all of the traditional heavy Javascript coding that you’d typically be doing in that sort of scenario.

So rather than creating Javascript to link a button to an animation playback, it’s all done through the user interface, by dragging and dropping rather than having to physically type in the code yourself.”

Andringa adds: “Of course, we are still learning – and when we struggle, Concurrent are on hand to support us.

I’m not technical, but I’m getting the hang of it, especially Creo Illustrate, and I’m actually enjoying it.”

But in the long-term, says Kozlowski, “we would like to have the skills to do everything we want to do in-house.

The opportunities are endless and we are already discussing a new project where this could be used.”

AR adds value

The AR experiences that Boltight and Superbolt are developing together with Concurrent for the oil & gas exhibition in May will clearly demonstrate the value of AR.

With AR technology still being relatively new, there will be a level of ‘wow factor’ about its use on the stand.

But beyond this intrigue and fascination in what’s novel, there is certainly a usefulness to the technology in its ability to convey valuable information to the end user a lot quicker and easier than by other means.

This use for marketing purposes can also be expanded out to other use cases.

An obvious one is for assembly instruction guides, into which Superbolt has already expanded, as well as manuals and e-learning modules for online training.

“The next step will be to produce AR experiences for all the products in our range to enable customers to see how they will fit and work on their application.

Each of our experiences has other key information available such as videos, literature and maintenance procedures,” says Kozlowski.

Companies like Boltight and Superbolt are proving how the deployment of AR can impact marketing and sales, with the potential of the technology to be applied to other areas of the business in the near future.

As Khan says, “People are often wary of new technology like AR, but the more we can get them used to it, the more they’ll realise the potential and how powerful it can be and so the more it will take off.”